1948-1958 Land-Rover Petrol Engine Repair Manual

Complete engine overhaul procedures, valve timing adjustments, bearing clearance specs, and fuel system servicing for Series I models. Includes detailed torque specifications and technical data throughout.

Manual Preview

Sample pages from the 1948-1958 Land-Rover Petrol Engine Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Land Rover Series I Models (Engine A-16 to A-57) Petrol Engine Repair Manual | Comprehensive Technical Archive.

- Measured Engine Displacement: 1,595 cc (97.34 cu in) for 1948-51 models is specified as the total cylinder volume Architecture.

- Fundamental Power Output: For optimal performance, 52 hp at 4,000 rpm represents the maximum rated horsepower Benchmarks.

- Baseline Torque Specification: Maximum torque reaches 101 lb-ft (14 mKg) at 1,500 rpm — indicates peak crankshaft output Sequences.

- Integral Compression Ratio: The cylinder head requires 6.9 to 1 for standard combustion chamber pressure Logic.

- Operational Fuel Capacity: Tank volume is specified to 50 L (13.2 US gal) for service requirements Range.

- Published Valve Clearance: Inlet tappet gap controls 0.010 in (0.25 mm) — supports efficient valve operation Threshold.

Professional Workshop Service Manual & Technical Specifications

Commercial Operations Workshop Manual: Car Petrol Engine Restoration: Ford Model A (1948), Model B (1950), Model C (1954), Model D (1956), Model E (1958) Repository

Reference-Category: 1948-1958 Ford models A, B, C, D, E // System-Coverage: Engine systems, petrol fuel, ignition, lubrication, transmission assemblies // Reference-Category: Comprehensive engine data, torque specifications, component dimensional standards.

| Component | Documentation Scope | Reference Details |

|---|---|---|

| Engine Assembly | Complete engine systems documentation | Cylinder head, crankshaft, camshaft procedures included |

| Transmission System | Gearbox and transfer box components | Main gearbox, clutch assemblies documented |

| Fuel and Ignition | Petrol system controls and components | Carburetter specifications, distributor timing data |

| Lubrication System | Oil pump and bearing specifications | Relief valve settings, capacity requirements documented |

| Suspension | Front and rear spring assemblies | Shock absorber adjustments, bushing clearances |

Coverage is segmented into engine architecture covering petrol models, transmission systems encompassing gearbox assembly and transfer box operation, suspension and steering components addressing front and rear spring configurations and hydraulic damper adjustments, chassis frame alignment and maintenance procedures detailing battery support and structural integrity checks, cooling system components including radiator and thermostat configurations, and fuel system procedures presenting carburetter operation and sediment bowl maintenance protocols.

Comprehensive Architecture

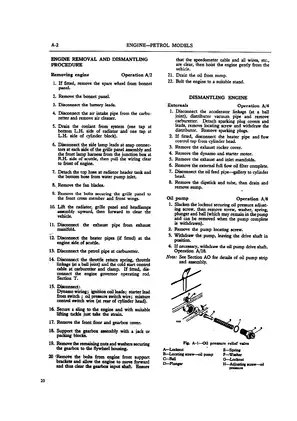

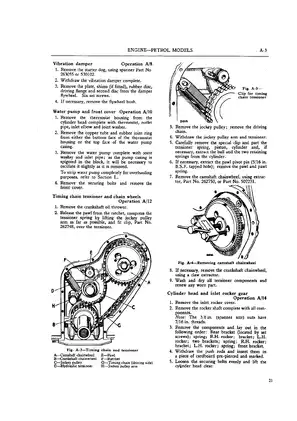

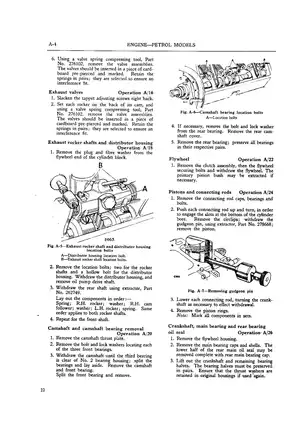

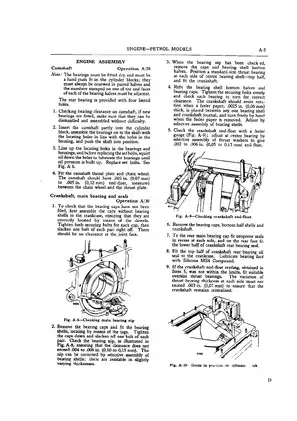

The document provides extensive technical guidance for petrol engine systems spanning complete engine removal, dismantling procedures, and reassembly sequencing. Covered topics encompass camshaft removal and fitment with bearing clearance specifications, crankshaft assembly with main bearing nip adjustments, piston ring gap verification, and cylinder liner installation with interference fit documentation. Procedures address connecting rod bearing selection, gudgeon pin clearance establishment, and flywheel run-out checking methodologies. Valve assembly operations include exhaust and inlet valve installation, valve guide and seat replacement protocols, and rocker gear assembly with tappet clearance adjustment.

Advanced Benchmarks

The manual documents specifications for multiple engine variants across the 1948-1958 production period, with distinct data sections addressing 1948-51 and 1952-58 model variations. Torque loadings are provided for cylinder head bolts, main bearing bolts, connecting rod assemblies, and flywheel securing hardware to ensure proper fastener fatigue prevention. Component dimensional data includes camshaft journal diameter clearances, crankshaft end-float measurements, valve timing specifications indicating inlet and exhaust opening and closing positions, and piston skirt clearance ranges. The document references specific tool part numbers and specialized equipment requirements throughout assembly procedures.

Strategic Standard

Transmission system documentation covers gearbox stripping, examination, and assembly procedures with detailed selector fork positioning, synchronizer clutch unit installation, and mainshaft gear end-float measurement techniques. Transfer box operation procedures encompass output shaft bearing adjustment, four-wheel drive dog clutch selector shaft configuration, and control linkage assembly. Suspension sections detail front and rear spring removal, bushing replacement methodologies, shock absorber installation with rubber bush nip specifications, and hydraulic damper functionality verification. Steering system guidance includes worm and nut type steering box assembly, rocker shaft end-float confirmation, ball joint lubrication protocols, and wheel alignment toe-in adjustment procedures.

Core Standard

Cooling system coverage includes water pump disassembly and spindle bearing examination, thermostat removal and testing procedures for both petrol and diesel variants, radiator filler cap pressure valve specifications, and system drain tap operation. Fuel system documentation presents carburetter jet configuration, accelerator pump membrane renewal, fuel filter element replacement procedures, and sediment bowl maintenance. Chassis and suspension information addresses frame alignment verification using diagonal measurements, spring leaf composition and free camber specifications, shock absorber rubber bushing compression dimensions, and brake pipe shield positioning. Lubrication system data specifies oil pump gear clearance ranges, relief valve spring free length measurements, and bearing lubrication specifications across petrol engine variants.

Comprehensive Interface

The manual provides defect location tables addressing engine starting failure symptoms and their remedial procedures, including battery condition assessment, starter motor functionality verification, and fuel system diagnostics. Engine performance defect sections cover stalling conditions, power loss identification, erratic operation causes, misfiring on acceleration factors, and valve mechanism noise determination. Bearing and lubrication defect matrices present oil pressure warning light interpretation, low oil pressure symptom analysis, and pump intake filter condition evaluation methodologies. Gearbox and transfer box defect location guides address gear change lever operation problems, freewheel mechanism functionality issues, and front-wheel drive control adjustment procedures. Steering system defect tables cover excessive backlash causes, tight steering identification, vehicle pulling or wandering symptom analysis, and wheel shimmy determination. Suspension defect information addresses spring leaf failure, shock absorber performance degradation, and bump rubber deterioration identification.

The document includes comprehensive wiring diagram references for horn button circuits, dipper switch connections, starter motor circuits, dynamo output configurations, and fuel gauge tank unit electrical integration. Assembly sequence illustrations demonstrate proper component orientation for camshaft bearing fitment, connecting rod cap alignment, piston ring installation, crankshaft thrust bearing positioning, cylinder head bolt tightening sequences, and timing chain wheel alignment. Maintenance procedure guidance covers engine decarbonization operations, valve grinding and lapping methodologies, piston and connecting rod removal techniques for both standard vehicles and those with transmission modifications, and external oil filter element renewal procedures for 1955-58 model variations.

The manual documents torque specifications for the [component] to ensure proper fastener fatigue prevention.

FAQ

Customer Reviews

Read what our customers say about this Ford Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)