Honda 90 Series Motorcycle Shop Manual (S90, CL90, CD90, C90, CT90)

S90 service documentation with engine, transmission, frame, electrical systems, troubleshooting guide, specifications and maintenance procedures for all models.

Manual Preview

Sample pages from the Honda 90 Series Motorcycle Shop Manual (S90, CL90, CD90, C90, CT90) manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda 90 Series (S90, CL90, CL90L, CD90, C90, CT90) — 1977–Onwards Technical Service Archive | 90 Series Repository.

- Established Securement Values: The engine cylinder bore and stroke measures 50×45.6 mm (1.97×1.80 in) is specified as the primary combustion displacement requirement Architecture.

- Operational Fluid Capacity: For engine lubrication, 0.9 L (1.9 US pint, 1.6 imp pint) is rated at the oil sump specifications Norms.

- Essential Gap Specs: The tappet clearance establishes 0.05 mm (0.002 in) for both inlet and exhaust valve adjustment settings Bounds.

- Baseline Power Draw: Maximum engine output governs 8.0 PS at 9,500 rpm — represents the net flywheel power output Topology.

- Approved Torque Specs: Peak crankshaft torque is designed for 0.65 kg-m (4.7 lb-ft) at 8,000 rpm on standard configurations Matrix.

- Measured Tension Specs: The primary reduction ratio sets 3.72:1 ratio for drive gear transmission specifications Standards.

Professional Workshop Service Manual & Technical Specifications

Unified Technical Repair Manual: Motorcycle Official Honda S90, CL90, CD90, C90, CT90 - Maintenance & Repair Reference Documentation-Framework

Design-Core: S90, CL90, CL90L, CD90, C90, CT90 motorcycle models // Asset-ID: Four-stroke Single-cylinder Engines / Chain-driven Overhead Camshaft Systems // Design-Core: 89cc displacement, 8.2:1 compression ratio, dual oil filtration system.

| System Component | Reference Data | Documentation |

|---|---|---|

| Engine Architecture | Chain-driven OHC, 75° tilted cylinder, semi-spherical combustion chamber | Complete technical specifications provided |

| Transmission Systems | Four-speed constant mesh (C90: three-speed), automatic and manual clutch variants | All gear ratios and reduction data documented |

| Brake Configuration | Internal expanding shoe, front and rear systems | Component inspection criteria included |

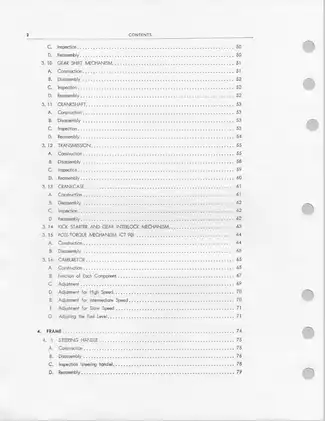

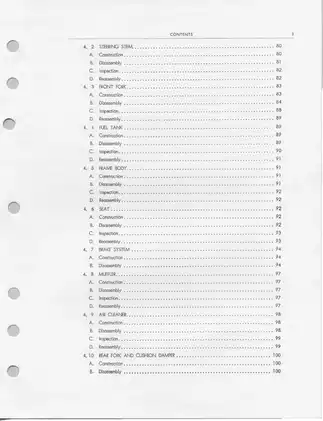

Diagnostic procedures address the comprehensive engine architecture alongside electrical and frame systems, conveying the fuel supply mechanism, ignition timing procedures, and lubrication protocols through systematic sector analysis. The manual encompasses the clutch assembly, transmission gears, crankshaft alignment, and cylinder head valve mechanisms, while systematically navigating suspension geometry, steering stem bearing adjustment, and frame integrity assessment. Further documented are the carburetor construction with main jet, needle jet, and air bleed hole specifications, along with drive chain tension parameters and brake shoe wear evaluation procedures. Additionally presented are front fork hydraulic dampening oil capacity requirements, rear cushion spring loading specifications, and wheel rim runout tolerance documentation.

Diagnostic Architecture

Calibration requirements are specified for tappet clearance, spark plug gap adjustment, and contact breaker point spacing to maintain precise valve timing and ignition performance across all engine speeds. The document provides cylinder compression pressure baselines, establishing compression ratio specifications and detailing remedial inspection protocols when pressure falls outside serviceable limits. Fuel system documentation covers the carburetor float chamber operation, choke mechanism functionality, and slow-speed mixture adjustment procedures through detailed component interaction analysis.

Technical Methodology

Electrical system documentation covers battery capacity ratings, spark plug specifications, alternator output measurements, and complete wiring harness routing for both general export and U.S.A. export variants across all model types. The ignition system section references timing mark alignment procedures, contact breaker point gap verification, and spark advance mechanism operation for synchronization with crankshaft rotation. Lighting system specifications include headlight wattage ratings, taillight and turn signal lamp data, with switching arrangement diagrams provided for main ignition circuit control.

Systematic Framework

Suspension service documentation covers telescopic front fork construction with hydraulic dampening fluid capacity specifications, spring free length measurements, and piston stop ring installation procedures alongside swing-arm rear suspension assembly with two-stage cushion damper oil fill requirements. Steering system data includes head pipe cone race bearing inspection protocols, trail angle references, and caster angle specifications for precise wheel alignment verification. Brake system documentation presents internal expanding shoe construction details, brake panel assembly procedures, and brake shoe wear thickness reference values for both front and rear wheel applications.

Strategic Architecture

Disassembly instructions are documented for the primary engine components including cylinder head removal sequencing, piston ring groove inspection methods, connecting rod bearing clearance measurement procedures, and crankshaft axial alignment verification on V-blocks. The clutch assembly section details wet multiple disc configurations with friction disc thickness specifications, primary drive gear backlash tolerance ranges, and proper torque application procedures for lock nut securing. Carburetor adjustment documentation presents high-speed fuel mixture control through main jet sizing, intermediate-speed regulation via jet needle clip positioning, and slow-speed mixture tuning through air screw rotation with specific idle RPM target values established for each model variant.

Structured Parameters

Wear limits are specified for valve stem diameters, valve seat contact width verification using bluing compounds, and piston ring end gap measurements to confirm proper combustion chamber sealing integrity. Front wheel assembly documentation includes brake shoe spring tension requirements, speedometer gear installation procedures, and axle bearing preload specifications alongside hub oil seal retention methods. The rear wheel section addresses final driven sprocket tooth count data, drive chain joint clip directional orientation, and chain tension adjustment through rear axle sleeve nut positioning with alignment mark references on both suspension arms. The manual documents torque specifications for the engine mounting bolts to ensure proper oscillation integrity.

Periodic maintenance scheduling provides inspection intervals at 500-kilometer and monthly increments with progressive intervals extending to 12,000 kilometers, addressing engine oil change procedures, oil filter screen cleaning, spark plug electrode gap verification, carburetor synchronization, and brake pad wear assessment. Troubleshooting protocols identify engine noise sources through tappet clearance variance analysis, spark plug fouling conditions from rich fuel mixture exposure, and fuel system blockage diagnosis through fuel cock flow verification procedures. The service tester operating instructions reference ignition coil secondary resistance measurement, battery output voltage evaluation, and A.C. generator performance confirmation under various engine speed conditions.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)