1985 Honda ATC70 Three-Wheeler Shop Manual

Complete engine, transmission, and chassis repair procedures. Detailed torque specifications, tool requirements, and troubleshooting for ATC70 models. Factory documentation with wiring diagrams and service bulletins included.

Manual Preview

Sample pages from the 1985 Honda ATC70 Three-Wheeler Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ATC70 (1985) — 1985 Specialized Analytical Sourcebook | ATC70 Series Package.

- Documented Tolerance Values: The engine displacement is standardized to 72 cc (4.4 cu in) operational Sequences.

- Measured Interference Fit: For optimal engine output, 3.6 BHP at 6,500 rpm is rated at peak crankshaft horsepower Baseline.

- Universal Electrical Load: The maximum torque specification sets 0.42 kg-m (3.04 ft-lb) at 5,000 rpm Requirements.

- Core Production Rate: The fuel tank capacity requires 4.3 liters (1.1 US gallons) for standard operation Threshold.

- Rated Imaging Specs: Engine oil capacity is calibrated to 0.7 liters (0.4 US quarts) service interval Mapping.

- Prescribed Clearance Data: Valve clearance specifies 0.05 mm (0.002 inches) intake and exhaust gap Configuration.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Calibration Parts Manual: Three-Wheeler Essential Repair Reference: Honda ATC70 Manual (1985) Troubleshooting-Index

Year-Coverage: 1985 ATC70 three-wheeler models // Assembly-Group: Engine and powertrain system documentation / Chassis and electrical logic // Year-Coverage: Complete factory service specifications for 1985 model production.

| Assessment-Parameter | System-Path | Context |

|---|---|---|

| Engine Components | Cylinder head, valve train, piston systems | Complete disassembly and inspection procedures documented |

| Drivetrain Assembly | Clutch, transmission, crankshaft, drive chain | Factory specifications for all transmission components |

| Chassis Systems | Front/rear wheels, steering, brake mechanisms | Suspension and brake service data included |

| Electrical Documentation | Ignition system, alternator, wiring | Complete electrical system reference with diagrams |

| Reference Materials | Torque specifications, tool requirements, service limits | Extensive specification tables throughout |

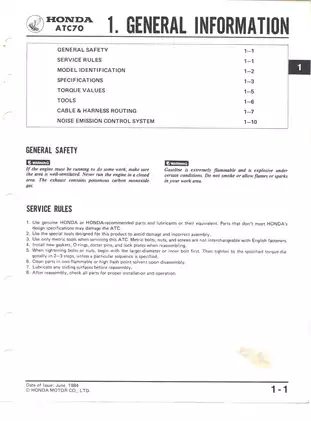

Maintenance information covers general service procedures, lubrication system documentation, fuel system component data, engine removal and installation sequences, cylinder head and valve operations, cylinder and piston specifications, clutch and gearshift linkage assembly procedures, recoil starter and alternator components, transmission and crankshaft assembly requirements, front wheel and steering assembly details, and rear wheel and brake system maintenance. The manual documents troubleshooting approaches for engine performance, electrical operation, clutch function, transmission shifting, steering and handling concerns, brake effectiveness, and overall vehicle diagnostics.

Technical Sequences

Technical specifications are provided for engine displacement (72 cc), bore and stroke dimensions (47.0 x 41.4 mm), compression ratio (7.53:1), and maximum horsepower (3.6 BHP at 6,500 rpm). The document includes carburetor identification data (PB38A), jet specifications (main jet #58, slow jet #38), and float level reference information (10.7 mm). Fuel tank capacity documentation is included (4.3 liters primary, 0.8 liters reserve), along with tire pressure specifications and rim size data. The manual documents torque specifications for the engine block, frame assembly, and drivetrain components to ensure proper mechanical fastener engagement.

Core Sequences

Factory specifications are documented for the four-speed transmission (primary reduction 4.058, final reduction 2.769), gear ratios for each position, and drive sprocket tooth counts (13T drive, 36T driven). Electrical system data includes spark plug specifications (NGK CR7HS or ND U22FSR-L), spark plug gap tolerance (0.6–0.7 mm), contact point gap range (0.3–0.4 mm), and ignition coil resistance values (primary 1.35–1.65 Ω, secondary 7.65–9.35 kΩ). Alternator coil resistance documentation is provided (2.43–2.97 Ω), along with condenser capacity specifications and starter system information.

Strategic Standard

Engine rebuild procedures are documented for valve clearance adjustment (0.05 mm intake and exhaust), cylinder compression testing (standard 1,200 ± 150 kPa, service limit 900 kPa), and piston ring specifications. The manual provides documentation for oil pump clearance tolerances (tip clearance 0.25 mm service limit, body clearance 0.20 mm service limit), oil filter rotor specifications, and recommended oil grades (SAE 10W-40). Valve guide replacement procedures and valve seat refacing data are included, along with stem-to-guide clearance specifications for both intake and exhaust valves.

Systematic Architecture

Drivetrain specifications are addressed in extensive detail covering clutch spring free length (25.08 mm standard, 23.1 mm service limit), disc thickness ranges (A: 2.55–2.65 mm, B: 3.35–3.45 mm), and plate warpage limits. Drive chain length specification (901.7 mm standard, 919.7 mm service limit for 72-pin chains) and adjustment procedures are documented. Brake system data includes rear brake drum internal diameter specifications (130 mm standard, 131 mm service limit), brake lining thickness standards (4.0 mm standard, 2.0 mm service limit), and brake lever free play ranges (15–20 mm).

Operational Interface

Reassembly procedures are specified for cylinder head installation with torque sequencing guidance, piston ring positioning (120-degree spacing for end gaps), and bearing preload specifications. The document provides complete wiring diagram reference with color coding (black, light green), engine stop switch continuity tables, and neutral switch operation data. Service bulletins address difficult shifting corrections and supply updated part numbers for transmission components. A comprehensive set-up instruction section covers pre-delivery assembly, with specific torque values for handlebar mounting, wheel installation, and drive chain adjustment. The manual documents torque specifications for the front axle nut, steering stem components, and brake system fasteners to ensure proper mechanical assembly security.

FAQ

Customer Reviews

Read what our customers say about this Honda Three-Wheeler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)