1987 Yamaha TZR250 Motorcycle Service Manual

TZR250 service documentation with complete engine overhaul, cooling system, and carburetion specs. Includes power valve diagnostics and transmission assembly procedures. Technical reference PN 2MA.

Manual Preview

Sample pages from the 1987 Yamaha TZR250 Motorcycle Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha TZR250 — 1987–1996 Advanced Digital Sourcebook | TZR250 Series Module.

- Calibrated Displacement Data: 249 cm³ (15.2 cu in) is measured at the engine cylinder volume Bounds.

- Rated Compression Ratio: For optimal performance, 5.9:1 is set to the combustion chamber pressure Topology.

- Published Fuel Capacity: 16.0 L (4.23 US gal) — limits the fuel tank volume Matrix.

- Authorized Engine Idle Speed: The carburetor requires 1,150–1,250 r/min for standard operation Standards.

- Maximum Wheelbase Specification: Wheelbase reaches 1,375 mm (54.1 in) dimensional framework Margin.

- Documented Seat Height: Seat height maintains 760 mm (29.9 in) from the ground level Protocol.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Diagnostic Reference Manual: Yamaha TZR250 Motorcycle Service Manual Wiring-Compendium

Subsystem-Focus: TZR250 (1987) // Service-Level: Comprehensive engine and transmission service logic // Subsystem-Focus: Complete technical documentation with wiring diagrams.

| Metric | Parameters | Calibration-Data |

|---|---|---|

| Engine Configuration | 2-stroke liquid-cooled parallel dual-cylinder, 249 cm³ displacement | Complete displacement and bore/stroke specifications documented |

| Fuel System | Twin Mikuni TM28SS carburetors with float chamber assemblies | Jet sizing, fuel level reference data, and float height documentation included |

| Electrical Architecture | 12V CDI ignition with A.C. magneto, voltage regulator, rectifier system | Timing curves, coil resistance values, and circuit operation data provided |

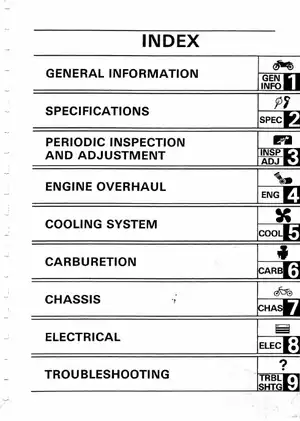

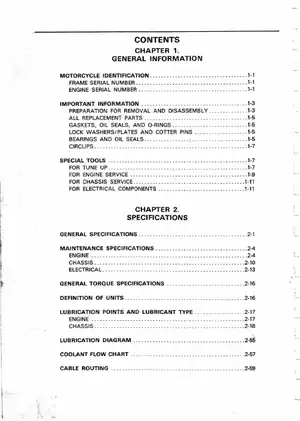

The repository is divided into engine overhaul procedures, cooling system maintenance, carburetion adjustments, chassis service operations, electrical diagnostics, and comprehensive troubleshooting sections. The documentation addresses transmission oil specifications, coolant replacement protocols, brake system verification, front fork servicing, and rear suspension tuning, while incorporating electrical system testing and component replacement sequences.

Integrated Protocol

Testing requirements are specified for spark plug gaps, ignition timing verification, and coolant system pressure checks. The manual includes specifications for the water pump impeller, thermostatic valve operation temperatures, and radiator cap opening pressures. Reed valve measurements, clutch friction plate thickness limits, and transmission axle runout tolerances are addressed within the inspection sections.

Strategic Threshold

Clearance measurements are addressed for piston-to-cylinder configurations, crankshaft bearing play, and clutch boss spline clearances. The documentation includes detailed reference data on engine oil capacity, transmission fluid volumes, and autolube pump output specifications. Wiring harness routing diagrams illustrate brake hose placement, throttle cable paths, and signal system lead configurations throughout the chassis assembly.

Integrated Logic-Path

Special procedures are addressed for carburetor synchronization between dual intake manifolds, Y.P.V.S. cable alignment with engine speed variation, and clutch cable adjustment relative to throttle opening. The manual documents oil pump clearance specifications, both tip and side clearance measurement protocols, and power valve holder bolt torque documentation to ensure proper component sealing.

Operational Framework

Verification procedures are included for brake fluid level inspection, fuel line integrity assessment, and cooling system leak detection using specialized testing equipment. The documentation provides reference specifications for steering head bearing preload settings, front fork spring rate data, and rear shock absorber gas pressure ranges. Wheel rim runout limits, brake disc thickness parameters, and tire pressure specifications based on load conditions are comprehensively detailed.

Diagnostic Parameters

Repair information is provided for valve clearance configuration data, oil seal installation techniques with application guidance on lubricant types, and bearing replacement procedures utilizing specialized puller tools. The manual documents torque specifications for cylinder head fasteners, crankcase bolts, and suspension mounting hardware to ensure proper assembly integrity. Wiring diagram annotations specify connector configurations, harness clamp locations, and cable routing clearances for the ignition, charging, lighting, and signal system circuits.

The document documents torque specifications for the crankshaft assembly to ensure proper rotational loosening prevention.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)