Husqvarna Viking 1+ / 1250 Embroidery Sewing Machine Owner's Manual

For Viking 1+ and 1250 models: includes diagnostics, operation, and sewing techniques for standard, decorative, and embroidery functions. Publication Part 412 40 75-26E.

Manual Preview

Sample pages from the Husqvarna Viking 1+ / 1250 Embroidery Sewing Machine Owner's Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Applied Shop Diagnostic Manual: Husqvarna Viking 1+ / 1250 Embroidery Sewing Machine Owner's Manual Service-Catalog

| Serial-Range: 1998 — 2008 // Design-Core: Embroidery Sewing Machine / Household Logic // Application-Range: Domestic Operation. | Assessment-Element | Technical-Path | Validation-Data |

|---|---|---|---|

| Design | Manufacturer Digest | Manufacturer Digest | |

| Advanced | Tactical Collection | Tactical Collection | |

| Technical | Expert Sourcebook | Expert Sourcebook | |

| Standard | Manufacturer Digest | Manufacturer Digest | |

| Principal | Tactical Collection | Tactical Collection | |

| Key | Expert Sourcebook | Expert Sourcebook | |

| Nominal Stitch Width Data | Maximum adjustable width is established at 0–6 mm (0–0.24 in) for precise needle positioning Benchmarks. | ||

| Prescribed Thread Tension Range | For optimal stitch quality, 5–6 represents the factory setting for normal sewing operations Specifications. | ||

| System Omnigram Feed Length | The eight-direction feed stitches maintain 0.8 mm (0.03 in) at standard speed Sequences. | ||

| Technical Embroidery Hoop Capacity | The sewing space limits embroidery work to 10×10 cm (3.9×3.9 in) per design Baseline. | ||

| Standard Illumination Requirements | Light fixture operates at 12 V with maximum power consumption of 5 W (incandescent bulb) Parameters. | ||

| Defined Edge Guide Measurement | Seam allowance guidance reaches 3.5 cm (1.38 in) maximum graduation on stitch plate Threshold. |

Following OEM groupings, the manual includes chapters on:

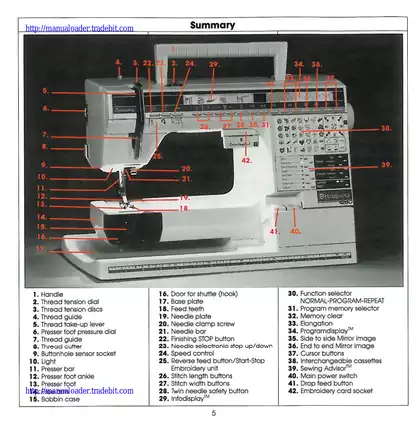

Introduction to Your Sewing Machine

Essential Setup and Threading Procedures

Mastering Standard and Decorative Stitches

Advanced Embroidery Unit Functions

Troubleshooting and Maintenance Guidelines

This manual documents torque specifications for selected components to ensure proper cyclic stress resistance.

Professional Workshop Service Manual & Technical Specifications

Applied Shop Diagnostic Manual: Husqvarna Viking 1+ / 1250 Embroidery Sewing Machine Owner's Manual Service-Catalog

Serial-Range: 1998 — 2008 // Design-Core: Embroidery Sewing Machine / Household Logic // Application-Range: Domestic Operation.

| Assessment-Element | Technical-Path | Validation-Data |

|---|---|---|

| Design | Manufacturer Digest | Manufacturer Digest |

| Advanced | Tactical Collection | Tactical Collection |

| Technical | Expert Sourcebook | Expert Sourcebook |

| Standard | Manufacturer Digest | Manufacturer Digest |

| Principal | Tactical Collection | Tactical Collection |

| Key | Expert Sourcebook | Expert Sourcebook |

| Nominal Stitch Width Data | Maximum adjustable width is established at 0–6 mm (0–0.24 in) for precise needle positioning Benchmarks. | |

| Prescribed Thread Tension Range | For optimal stitch quality, 5–6 represents the factory setting for normal sewing operations Specifications. | |

| System Omnigram Feed Length | The eight-direction feed stitches maintain 0.8 mm (0.03 in) at standard speed Sequences. | |

| Technical Embroidery Hoop Capacity | The sewing space limits embroidery work to 10×10 cm (3.9×3.9 in) per design Baseline. | |

| Standard Illumination Requirements | Light fixture operates at 12 V with maximum power consumption of 5 W (incandescent bulb) Parameters. | |

| Defined Edge Guide Measurement | Seam allowance guidance reaches 3.5 cm (1.38 in) maximum graduation on stitch plate Threshold. |

Analytically demanding sewing procedures are documented for this advanced machine. The manual covers system diagnostics, calibration requirements, and specific operational parameters. It details electrical system documentation, including components and wiring. Suspension service documentation is provided, alongside disassembly instructions for key parts.

Understanding Machine Components

Service procedures are documented for essential mechanical parts, ensuring optimal operation. This includes guidance on threading, bobbin winding, and stitch selection for various fabric types.

Utilizing Special Functions

Calibration requirements are specified for advanced functions like embroidery, buttonholes, and programmed patterns. The manual guides users through setup and operation for specialized presser feet and accessories.

Troubleshooting and Maintenance

Electrical system documentation covers troubleshooting common issues and maintenance schedules. Information on replacing parts, cleaning, and adjustments is provided to ensure longevity and performance.

Advanced Features and Accessories

Suspension service documentation covers the feed teeth and presser foot mechanisms. Disassembly instructions are documented for key components to facilitate cleaning and repairs, ensuring the machine's functional integrity.

This manual documents torque specifications for selected components to ensure proper cyclic stress resistance.

FAQ

Customer Reviews

Read what our customers say about this Husqvarna Sewing Machine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)