1979-1987 Ford 1100-2110 Tractor Shop Manual

Ford 1100 through 2110 tractor technical documentation covering service procedures and specifications. Complete repair reference for two-wheel and four-wheel drive models from 1979-1987.

Manual Preview

Sample pages from the 1979-1987 Ford 1100-2110 Tractor Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ford 1100–2110 Tractor Series — 1979–1987 Manufacturer Tactical Expert | Nonsynchromesh Technical Guide Library Module.

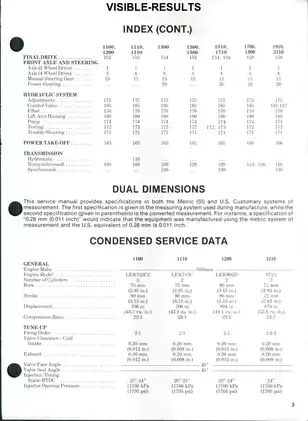

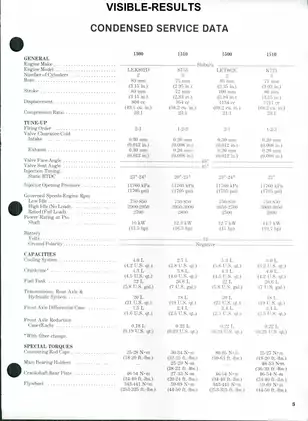

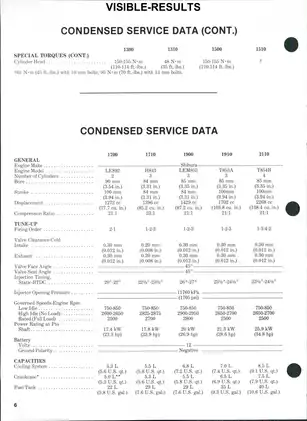

- Prescribed Native Resolution: 706–2268 cc cylinder displacement is designed for the two to four cylinder engine architecture framework.

- Standard Clamp Forces: Connecting rod cap torque reaches 24–83 N·m (18–62 ft-lbs) establishes secure fastening protocol norms.

- Maximum Fluid Levels: Fuel tank capacity spans 14–40 L (3.7–10.6 US gal) requires appropriate storage margins bounds topology.

- System Wattage Specs: Engine power output is configured at 8.2–25.9 kW (11–34.8 hp) at rated load specifications.

- Calibrated Cold Start Limits: Glow plug system operates on 12-volt negative ground is measured at combustion initiation architecture.

- Nominal Scan Resolution: Valve clearance is established at 0.20–0.30 mm (0.008–0.012 inch) intake and exhaust standards topology.

Professional Workshop Service Manual & Technical Specifications

Specialized Maintenance Workshop Manual: Tractor Ford 1100, 1110, 1200, 1210, 1300, 1310, 1500, 1510, 1700, 1710, 1900, 1910, 2110 Tractor SHOP Manual 1979-1987 Knowledge-Base

Performance-Values: Ford 1100 through 2110 tractor models (1979-1987 production) // Series-Validation: Multi-cylinder diesel engine configuration with transmission system logic // Machine-Range: Two and four-wheel drive variants with hydrostatic and nonsynchromesh transmission options.

| Metric | Technical-Path | Framework |

|---|---|---|

| Engine Specifications | Diesel combustion systems documented | Complete reference data provided |

| Transmission Systems | Hydrostatic, nonsynchromesh, and synchromesh pathways | Comprehensive assembly documentation |

| Hydraulic Components | Lift system control architectures | Procedural components detailed |

| Electrical Configuration | Charging and starting circuit layouts | Wiring diagrams for all model variations |

| Brake and Drive Systems | Final drive and power take-off assemblies | Assembly and removal procedures included |

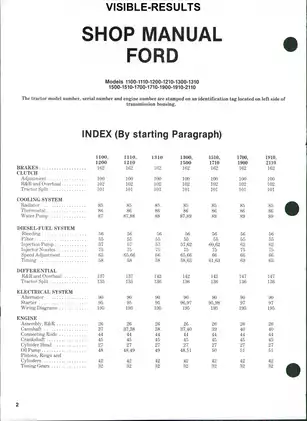

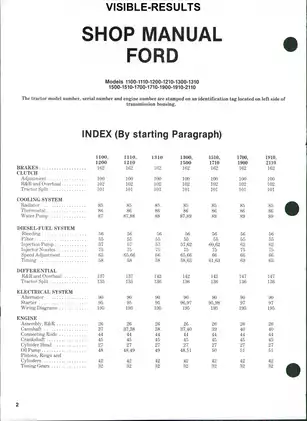

Outlining the operational framework across thirteen tractor models, this manual encompasses engine assembly procedures, transmission maintenance covering hydrostatic and standard gearbox configurations, and hydraulic lift system operations, documents cooling system specifications for pressurized radiator assemblies, and covers electrical system components including alternator regulation and starter motor service. The document provides front axle and steering gear information for both two-wheel and four-wheel drive configurations, describes differential carrier bearing adjustments and bevel gear mesh positioning, and includes power take-off drive arrangements for both standard and mid-mount installations.

Structured Benchmarks

Maintenance guidelines are included for clutch adjustment and service procedures across single and dual plate designs. The manual documents torque specifications for engine fasteners to ensure proper component retention.

Integrated Nexus

OEM guidelines are included for fuel system bleeding, injection pump timing verification, and diesel injector nozzle testing protocols. Transmission service information covers gear backlash measurement, shift fork clearance verification, and synchronizer cone wear assessment.

Strategic Framework

HVAC system procedures are included for radiator hose routing, thermostat operation, and water pump bearing preload calibration on all model configurations. The manual addresses differential assembly overhaul including ring gear and pinion installation with mesh position verification.

Precise Framework

Torque specifications are documented for cylinder head fastening to ensure proper gasket sealing and engine integrity. The document includes reference data for brake drum specifications, final drive gear replacement, and hydraulic cylinder rod assembly on all production variants.

Precise Nexus

The manual provides an indexed reference structure with condensed service data tables listing engine specifications by model, including bore and stroke dimensions, firing order sequences, valve clearance reference points, and compression ratio values. Hydraulic system pressure relief settings are referenced, along with flow control valve adjustment procedures and lift arm positioning feedback mechanisms for single and dual-lever control configurations. Wiring diagrams are included for all electrical system configurations, documenting battery connections, glow plug circuits, lighting layouts, and safety start switch installations.

FAQ

Customer Reviews

Read what our customers say about this Ford Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)