2002 Mercury 30/40 EFI FourStroke Outboard Motors Service Manual

Mercury 30/40 EFI FourStroke — Electronic Fuel Injection, powerhead diagnostics, cylinder head/block service, mid-section assembly, gearcase procedures. PN 90-883064

Manual Preview

Sample pages from the 2002 Mercury 30/40 EFI FourStroke Outboard Motors Service Manual manual

Purchase & Download

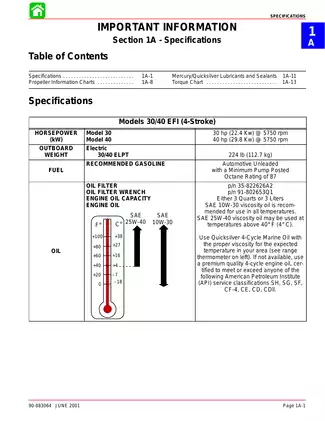

Models Covered & Key Technical Specifications

Mercury 30/40 EFI FourStroke (90-883064) — 2002

Strategic Operational Compendium | 30/40 FourStroke EFI Edition.

- Established Form Factor: Engine displacement reaches 747 cc (45.6 cu in) for the comprehensive outboard architecture Bounds.

- Operational Output Quality: Horsepower rating controls 30 hp at 5750 rpm for the 30 EFI model, delivering peak marine performance Topology.

- Certified Fastener Specs: Spark plug gap is measured at 0.040 in (1.0 mm) across all three cylinders, ensuring proper ignition Matrix.

- Factory Tolerance Values: Valve clearance cold requires intake setting of 0.006–0.010 in (0.15–0.25 mm) and exhaust at 0.010–0.014 in (0.25–0.35 mm) Standards.

- Approved Amperage Specs: Alternator output delivers 12.6 V–20 Amps (252 Watts) rectified and regulated for battery charging margin Protocol.

- Measured Unit Dimensions: Transom height specification indicates 20 in (51 cm) long shaft configuration for standard installation envelope Guidelines.

Professional Workshop Service Manual & Technical Specifications

Commercial Manual: Outboard Motor Official Mercury 30 EFI (2002) & 40 EFI (2002) FourStroke Outboard Motors - Factory Diagnostics & Repair Procedures Procedure-Library

Technical-Benchmarks: Mercury 30/40 EFI FourStroke (2002+) // Architecture-Focus: Electronic Fuel Injection System Logic // Technical-Benchmarks: Multi-section service framework with 594-page specifications.

| Characteristic | Component Reference | Documentation |

|---|---|---|

| Powerhead Systems | Cylinder head, crankshaft, lubrication components | Complete specifications included |

| Electrical Assembly | Ignition timing, charging, starting systems | Detailed circuit descriptions provided |

| Fuel Delivery | EFI sensors, fuel injectors, pressure regulators | Comprehensive sensor data documented |

Correctly requiring thorough documentation, this service reference encompasses cylinder head servicing alongside crankshaft inspection procedures. The document encompasses mid-section systems including power trim and steering bracket maintenance, proceeding through lower unit gear housing protocols. Coverage is segmented into important information alongside electrical system details, then transitions toward electronic fuel injection theory of operation, which addresses troubleshooting and diagnostics methodology. Service procedures span mechanical fuel pump configuration through vapor separator assembly techniques, examining emissions control information alongside cylinder block reassembly protocols. The manual explores lubrication system function by detailing oil pump architecture, then progresses through mid-section maintenance covering clamp/swivel bracket operation, power trim hydraulic circuits, and manual tilt assist mechanisms. Lower unit procedures document gear housing configurations for non-Bigfoot and Bigfoot assemblies. Attachment and control linkage sections address throttle/shift linkage calibration alongside tiller handle installation. Color wiring diagrams conclude the reference material.

Operational Threshold

Timing procedures are documented for ignition advance verification at idle and wide-open throttle conditions. The manual documents torque specifications for the fastener assembly to ensure proper corrosion joint prevention. Technical notes are provided for crank position sensor calibration and manifold absolute pressure sensor operation, ensuring electronic control module function. Valve clearance reference data is included for intake and exhaust valve adjustment procedures at cold engine temperature.

Diagnostic Topology

Quality checks are addressed for compression verification using specified psi measurement methodology across all three cylinders. The cylinder leakage testing chapter includes detailed procedures for identifying defective intake valves, exhaust valves, piston rings, and head gasket conditions. Engine coolant temperature sensor resistance specifications enable troubleshooting of temperature-dependent control functions. Fuel system vacuum and pressure testing methodologies establish baseline performance criteria.

Advanced Benchmarks

The troubleshooting chapter addresses Guardian protection system activation parameters, including overheat speed control and low oil pressure speed control thresholds. Engine speed limiter settings prevent operation beyond 6350 rpm under full cylinder conditions. Battery voltage monitoring specifications range from 10 volts minimum to 16 volts maximum for system protection. Manifold absolute pressure sensor interpretation guides technicians through load-based fuel delivery calculation.

Comprehensive Standard

The powerhead removal section documents mounting bolt sequences and torque procedures for proper engine separation from the mid-section. Crankcase cover installation guidance includes Loctite Master Gasket application methodology and center bolt two-stage tightening protocol. Cylinder head installation encompasses bolt torque sequences progressing through 17 lb-ft initial tension to 35 lb-ft final specification. Lower unit attachment procedures detail bearing carrier nut torque and trim tab screw fastening.

Engineered Sequences

The intake manifold assembly removal procedure requires high-pressure fuel line depressurization before service. Fuel injector extraction utilizes specialized cap tool methodology to prevent fuel system component damage. Throttle body removal necessitates intake manifold disassembly as a prerequisite step. Electronic control module connector disconnection and bracket removal must precede intake assembly separation from the cylinder block.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)