1989 Yamaha PZ480P / PZ480EP / Phazer II Service Manual

Troubleshooting, parts diagrams, and service data for the 1989 Yamaha PZ480P, PZ480EP, and Phazer II snowmobiles. Documents engine, drive train, and chassis systems. Part number LIT-12618-01-23.

Manual Preview

Sample pages from the 1989 Yamaha PZ480P / PZ480EP / Phazer II Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha PZ480P / PZ480EP (LIT-12618-01-23) -- 1989 Detailed Maintenance Digest | Snowmobile Bundle. Prescribed Addressable Resolution: 1.0 mm (0.04 in) is established at belt wear limit. Standard Bolt Torques: 15 Nm (1.5 m • kg, 11 ft • lb) dictates handlebar bolt torque. Maximum Tank Capacity: 250 cm³ (8.8 imp oz, 8.5 US oz) corresponds to oil capacity. System Dimensional Tolerance: 0.03 mm (0.0012 in) yields cylinder head warpage limit. Calibrated Climate Parameters: 0°C (32°F) is set to standard conditions. Nominal Imaging Specs: 1,500 – 1,700 r/min is established at engine idle speed.

Professional Workshop Service Manual & Technical Specifications

Detailed Maintenance Manual: Snowmobile 1989 Yamaha PZ480P / PZ480EP / Phazer II Service Manual Logic-Archive

Unit-Designations: Yamaha PZ480P / PZ480EP / Phazer II (LIT-12618-01-23) // Validation-Data: Snowmobile / Engine Logic // Technical-Domain: Service Manual-Archive.

| Identifier | Diagnostic-Logic | Calibration-Data |

|---|---|---|

| Machine Identification | 1989 Yamaha Models | Serial Number Information |

| Periodic Maintenance | 20/40/80/1600 km Intervals | Ignition Timing Adjustment Range |

| Engine Overhaul | Cylinder/Piston Specs | Crankshaft Bearing Torque |

| Carburetor Tuning | Jet Sizes for Altitude | Idle Speed Settings |

| Electrical System | Fuse Amperage Ratings | Circuit Diagrams Included |

| Specifications | Unit Definitions | Cable Routing Diagrams |

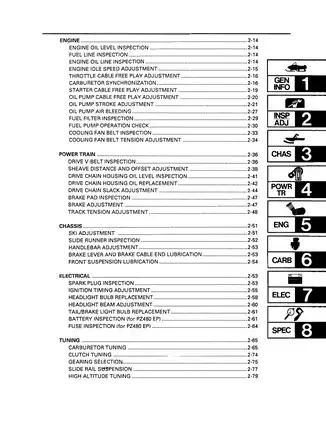

Maintenance hierarchies are structured into chapters covering general information, periodic inspections, engine overhaul, and specific system repairs.

The documentation addresses

various components, including the engine, power train, chassis, and electrical systems, with detailed diagrams and procedures.

Assembly instructions are detailed for

key sub-assemblies such as the primary and secondary sheaves, drive chain housing, and magneto rotor, providing step-by-step guidance.

Hydraulic schematics are included for

relevant systems, ensuring a clear understanding of fluid pathways and component interactions.

Steering component information is provided for

complete serviceability, from handlebar adjustments to ski alignment procedures.

Inspection guidelines are provided for

all major components, helping to identify wear, damage, and potential issues before they lead to failure.

This manual documents torque specifications for critical fasteners to ensure proper axial load stability.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)