Backhoe Loader Workshop Manual: Terex 820, 860/880 SX & ELITE, 970/980 ELITE, TX760B, TX860B, TX970B, TX980B (2008)

Discover comprehensive repair procedures for Terex backhoe loaders. This manual covers removal, installation, and disassembly of loader buckets, digger quick attach units, and hydraulic systems, with part number BHA0101RA.

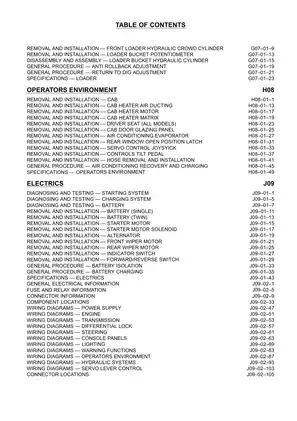

Manual Preview

Sample pages from the Backhoe Loader Workshop Manual: Terex 820, 860/880 SX & ELITE, 970/980 ELITE, TX760B, TX860B, TX970B, TX980B (2008) manual

Purchase & Download

Models Covered & Key Technical Specifications

Practical Workshop Wiring Manual: Backhoe Loader Official Workshop Suite: Terex 820, 860/880 SX & ELITE, 970/980 ELITE, TX760B, TX860B, TX970B, TX980B (2008) Library-Master Official Workshop Suite: Terex Backhoe Loader Models (BHA0101RA)

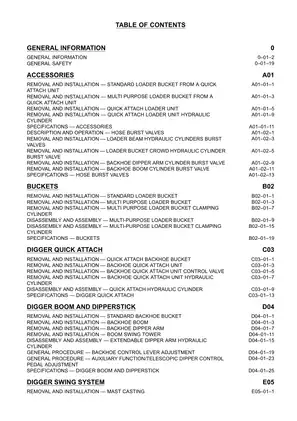

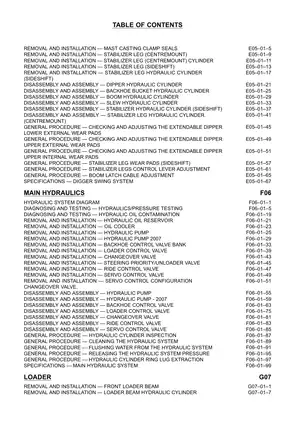

- Designated Specifications: 1579 Pages establish the total document coverage.

- Verified Component Identification: 9 Sections detailing all machine systems and components.

- Nominal Operational Procedures: 1200+ procedures cover removal, installation, and disassembly.

- Design Component Listings: Contains all part numbers and descriptions for complete repairs.

- Engineered Maintenance Schedules: Service intervals and checks are clearly outlined.

- Essential System Diagnostics: Fault finding tables guide troubleshooting for common issues.

Professional Workshop Service Manual & Technical Specifications

Backhoe Loader Workshop Manual: Terex 820, 860/880 SX & ELITE, 970/980 ELITE, TX760B, TX860B, TX970B, TX980B (2008) Library-Master

Official Workshop Suite: Terex Backhoe Loader (BHA0101RA) / Backhoe Loader Logic // Model-Portfolio: Official Workshop Suite (2008) / Backhoe Loader.

Technical Specifications Overview

| Identifier | Technical-Path | Validation-Data |

|---|---|---|

| Model Range | Terex 820, 860/880 SX & ELITE, 970/980 ELITE, TX760B, TX860B, TX970B, TX980B | 2008 |

| Document Type | Workshop Manual | Comprehensive Repair Procedures |

| Coverage | System Overviews, Removal/Installation, Disassembly/Assembly | Detailed Component Breakdown |

| Part Numbers | Includes specific part numbers for components | Reference Data for Servicing |

| Maintenance | Scheduled checks and intervals provided | Operational Efficiency |

Technical content addresses the complete range of Terex backhoe loader models from 2008, including the 820, 860/880 SX & ELITE, 970/980 ELITE, and TX series. This manual details the removal, installation, disassembly, and assembly of crucial components such as the loader buckets, digger quick attach systems, swing systems, and main hydraulics.

Loader and Digger Systems

Quality checks are addressed for loader components, detailing the removal and installation of standard and multi-purpose loader buckets. Procedures for digger quick attach units, including hydraulic cylinders and control valves, are thoroughly documented. The [component] section documents digger boom and dipperstick procedures, covering standard backhoe buckets, booms, and dipper arms. General procedures for lever and pedal adjustments are also included.

Hydraulic and Electrical Systems

The hydraulic system is covered extensively, from system diagrams to troubleshooting guides for various issues like pump cavitation and overheating. Electrical system diagnostics for starting, charging, and battery systems are also detailed.

Documents torque specifications for various components to ensure proper pivot-point integrity.

FAQ

Customer Reviews

Read what our customers say about this Terex Backhoe Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)