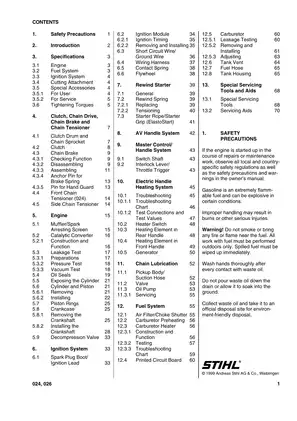

STIHL 024 & 026 Chainsaw Service Manual

This service manual contains detailed descriptions of all the repair and servicing procedures specific to this power tool series. Reference is made to these handbooks in the appropriate chapters of this manual.

Manual Preview

Sample pages from the STIHL 024 & 026 Chainsaw Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

STIHL 024 & 026 Chainsaw (Part Number: 1121-791-7300) - Comprehensive Maintenance Guide Parts-Reference

STIHL 024/026 Crankcase Repository | STIHL Chainsaw

- Nominal Coupling Torques: 3.0 Nm is specified as the torque for the pan head screw, securing the cover plate and chain tensioner Components.

- Prescribed Twist Specifications: For optimal operation, 2.5 Nm is configured at the torque for the countersunk screw, securing the cover plate and chain sprocket cover.

- System Calibrated Holding Capacity: 23.0 Nm -- signifies the torque for the collar screw, for bar mounting.

- Calibrated Load Capacity: The collar screw requires 30.0 Nm for bar mounting.

- Documented Cycle Rate: The IS-M4x12 spline screw requires 3.0 Nm for the cover to crankcase.

- Defined Torque Data: For the M10x1 screw, 14.0 Nm is specified as the torque for the decompression valve.

Professional Workshop Service Manual & Technical Specifications

STIHL 024 & 026 Chainsaw Service Manual: STIHL 024 & 026 Chainsaws (1999) - Comprehensive Maintenance Guide Parts-Reference

Conceptual-Layout: STIHL 024, 026 (1999) // Subsystem-Focus: Chainsaw / Engine Logic // Conceptual-Layout: Comprehensive repair and maintenance data.

| Service-Nexus | Diagnostic-Logic | Context |

|---|---|---|

| Ignition System | 6.1 Spark Plug Boot/Ignition Lead | 33 Nm |

| Engine | 5.1 Muffler/Spark Arresting Screen | 10 Nm |

| Clutch, Chain Drive, Chain Brake and Chain Tensioner | 4.3 Chain Brake | 4.0 Nm |

| Fuel System | 12.5 Carburetor | 0.8 bar |

| Ignition System | 6.2 Ignition Module | 7.0 Nm |

| Engine | 5.3 Leakage Test | 0.5 bar |

Major sections focus on:

Introduction

The documentation addresses the overall design concept of the 024 and 026 chainsaws, noting that descriptions and servicing procedures generally apply to both, with differences described in detail. Assembly stand requirements and the importance of using original STIHL replacement parts are also highlighted.

Engine

Assembly instructions are detailed for the muffler, spark arresting screen, and catalytic converter, including construction and function. Procedures for leakage tests, oil seals, the cylinder, and piston are covered.

Ignition System

Hydraulic schematics are included for the ignition system, covering the spark plug, ignition module, and flywheel. Troubleshooting for the ignition system is also provided.

Chain Lubrication

Steering component information is provided for the oil pump, pickup body, and suction hose, detailing servicing procedures for the valve.

Fuel System

Inspection guidelines are provided for the fuel system, including the air filter, choke shutter, and carburetor preheating. Carburetor testing and adjustment procedures are also documented.

documents torque specifications for component alignment retention to ensure proper component alignment retention.

FAQ

Customer Reviews

Read what our customers say about this Stihl Chainsaw manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)