Hitachi Zaxis Technical & Workshop Manual for ZX160LC-3, ZX180LC-3, ZX180LCN-3 Excavators (2006-2012)

Manual Preview

Sample pages from the Hitachi Zaxis Technical & Workshop Manual for ZX160LC-3, ZX180LC-3, ZX180LCN-3 Excavators (2006-2012) manual

Purchase & Download

Models Covered & Key Technical Specifications

Zaxis 160LC-3, Zaxis 180LC-3, Zaxis 180LCN-3 / Hitachi Ltd Corporation

ZAXIS 160LC-3 (2006-2012) ZAXIS 180LC-3 (2006-2012) ZAXIS 180LCN-3 (2006-2012)

Production years (depending on model): 2006, 2007, 2008, 2009, 2010, 2011, 2012

Professional Workshop Service Manual & Technical Specifications

Hitachi Zaxis ZX160LC-3, ZX180LC-3 and ZX180LCN-3 Excavator Technical & Workshop Manual (2006-2012)

This comprehensive service bundle combines the Technical Manual (Operational Principle & Troubleshooting) and the Workshop Manual for the Hitachi Zaxis Series 3 hydraulic excavators. Spanning over 1,000 pages of factory-level information, this is the definitive resource for professional mechanics and fleet owners requiring precise data for maintenance, diagnostic procedures, and complex repairs.

This manual set is specifically designed for the following Hitachi Zaxis models:

- ZX160LC-3 (2006-2012)

- ZX180LC-3 (2006-2012)

- ZX180LCN-3 (2006-2012)

Applicable Serial Numbers:

- ZX160LC-3: 040001 and up

- ZX180LC-3, 180LCN-3: 020001 and up

Maximum Performance Through Technical Depth

This manual provides an unfair advantage for troubleshooting by explaining the "why" behind the machine's operation. With the integrated "Operational Principle" section, you gain a deep understanding of the hydraulic and electrical logic, allowing for faster diagnostics and reducing machine downtime.

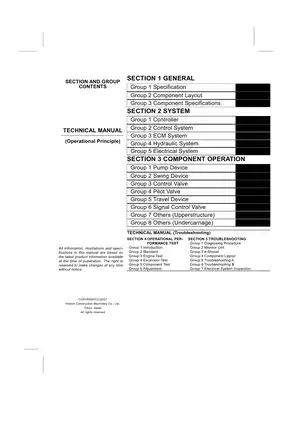

Detailed Table of Contents

SECTION 1: GENERAL

- Group 1: Specification (Dimensions, Working Range, Weight)

- Group 2: Component Layout (Main Component Locations)

- Group 3: Component Specifications (Engine, Pump, Motors, Valves)

SECTION 2: SYSTEM

- Group 1: Control System (Engine, Pump, and Valve Control)

- Group 2: ECM System (Engine Control Module Logic)

- Group 3: Hydraulic System (Main Circuit, Pilot Circuit)

- Group 4: Electric System (Circuit Diagrams, Monitoring)

SECTION 3: COMPONENT OPERATION

- Group 1: Pump Device (Regulator Operation)

- Group 2: Swing Device (Motor and Brake Function)

- Group 3: Control Valve (Spool and Relief Valve Logic)

- Group 4: Travel Device (Counterbalance and Brake Valves)

- Group 5: Others (Upperstructure Components)

- Group 6: Others (Undercarriage Components)

SECTION 4: OPERATIONAL PERFORMANCE TEST

- Group 1: Introduction (Preparation for Testing)

- Group 2: Standard (Performance Standards Table)

- Group 3: Engine Test

- Group 4: Machine Performance Test (Travel, Swing, Attachment)

- Group 5: Component Test (Pressure and Flow Checks)

SECTION 5: TROUBLESHOOTING

- Group 1: General (Diagnostic Codes and Procedures)

- Group 2: Troubleshooting A (Machine and Engine Diagnosis)

- Group 3: Troubleshooting B (Hydraulic Systems)

- Group 4: Troubleshooting C (Electrical Systems)

WORKSHOP MANUAL (REPAIR SECTION)

- Removal and Installation of Main Components

- Disassembly and Assembly of Pump, Motors, and Valves

- Engine Maintenance Procedures

- Undercarriage Service (Track Adjusters, Rollers, Idlers)

Why This Manual is Essential

- Mobile-Optimized Structure: Clear headings and grouped sections make it easy to find specific torque specs or wiring diagrams on a smartphone or tablet while in the field.

- Factory Accuracy: Uses original Hitachi terminology and diagrams, ensuring you follow the same procedures as dealership technicians.

- Safety First: Includes critical safety precautions and torque specifications to ensure repairs are performed correctly and securely.

Maintain the value of your Hitachi Zaxis equipment by using the correct technical documentation for all service and repair tasks.

FAQ

Customer Reviews

Read what our customers say about this Hitachi Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)