1968-1976 Yamaha 80-175cc Piston-Port Service Manual

Troubleshooting, removal sequences, and maintenance for piston-port engine control systems, carburetor assembly, transmission service, and brake/suspension components across 11 motorcycle models

Manual Preview

Sample pages from the 1968-1976 Yamaha 80-175cc Piston-Port Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha AT1, AT2, DT125, DT175, CT1, CT2, MX100, MX125, YZ80, YZ125, MX175 (1968-1976 Piston-Port Series) — 1968–1976 Comprehensive Structured Compendium | Piston-Port Motorcycle Toolkit.

-

Established Tension Specs: Cylinder head nuts are rated at 14.5 ft.-Ib. (2.0 mkg) for all models except 80cc engines (7.3 ft-Ib.) which specifies secure fastening requirement Matrix.

-

Operational Locking Torques: Flywheel nut, rear sprocket nuts, and engine sprocket retainer establish 3.5–4.0 ft.-Ib. (0.49–0.56 mkg) torque securement Standards.

-

Calibrated Displacement Data: The piston ring gap is specified at 0.006–0.014 in. (0.15–0.33mm) for 80–100cc engines, governing combustion chamber sealing Protocol.

-

Factory Circuit Specs: For models DT175, MX175, and CT series, spark plug gap must achieve 0.071 in. (1.8mm) BTDC timing margin Architecture.

-

Approved RPM Specs: Idle speed for 80–100cc models reaches 900–1,000 rpm while 125–175cc models achieve 1,000–1,200 rpm, maintaining optimal low-speed performance Norms.

-

Measured Fastening Values: Fork cap and stem bolts require 4.0–4.5 ft.-Ib. (0.56–0.63 mkg) — establishes the steering assembly strength configuration Standards.

Professional Workshop Service Manual & Technical Specifications

Consolidated Workshop Manual: Yamaha 80-175cc Piston-Port Service & Repair Reference

Operational-Framework: AT1, AT2, DT125, DT175, CT1, CT2, MX100, MX125, YZ80, YZ125, MX175 (1968-1976 models) // System-Coverage: Multi-system technical documentation covering mechanical, electrical, and chassis assemblies // Operational-Framework: 196-page comprehensive reference with wiring diagrams and component specifications.

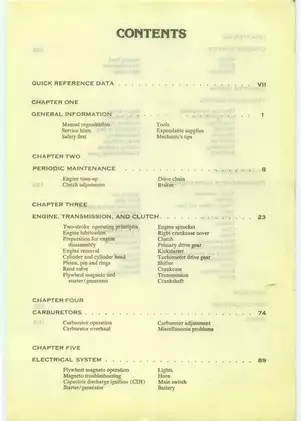

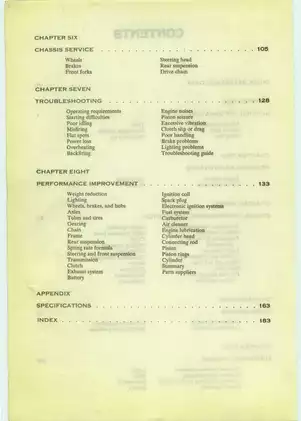

| Document Section | Coverage Area | Content Details |

|---|---|---|

| General Information | Foundational content | Manual organization, service methodology, safety framework, required tooling (special tools with costs and sourcing included) |

| Periodic Maintenance | Routine service schedule | Engine tune-up procedures, compression testing methodology, carbon deposit removal reference, ignition timing documentation, electrical system checks, fluid service intervals |

| Engine & Transmission | Core mechanical systems | Two-stroke operating principles explained, piston-port and reed valve system documentation, cylinder and crankshaft assembly information, clutch types (four variants documented), transmission assembly data |

| Carburetors | Fuel system documentation | Carburetor operating principles across throttle ranges, Mikuni carburetor variants (independent and single-unit float models), float level reference data, component modification options |

| Electrical System | Power and ignition systems | Flywheel magneto operation, battery ignition circuit documentation, capacitor discharge ignition (CDI) wiring, starter/generator assembly, charging circuit test procedures, battery maintenance reference |

| Chassis Service | Suspension and braking | Wheel bearing service information, brake shoe assembly documentation, front fork disassembly/reassembly sequences, steering head geometry, rear suspension adjustment reference, drive chain tension documentation |

| Troubleshooting | Diagnostic framework | Starting difficulty diagnosis methodology, ignition system checks, carburetor mixture analysis, mechanical condition assessment procedures, comprehensive symptom-to-cause reference guide (Table 1) |

| Performance Modification | Enhancement documentation | Weight reduction techniques across components, suspension tuning formula (wheel rate calculation methodology), ignition system upgrade options, port modification dimensions for various engine sizes, jetting adjustment guidance |

The service manual covers procedural documentation for all major systems including engine assembly sequences, transmission gear ratio tables (4-speed and 5-speed configurations documented for multiple models), electrical wiring diagrams for magneto and battery systems, fuel system component specifications, suspension geometry data, and comprehensive parts supplier directory. The document includes torque specifications for critical fasteners ensuring proper assembly of cylinder heads, flywheels, and engine sprockets. Extensive specification tables organize model-specific data (dimensions, weight, performance figures, carburetor settings, ignition timing values) across eight engine size categories from 72cc through 171cc displacement. The manual documents carbon deposit removal techniques, spark plug condition analysis (eight plug condition photographs with interpretation guidance), brake shoe replacement procedures, and electrical system troubleshooting flowcharts. Wiring diagrams illustrate magneto charging circuits, battery ignition systems, and lighting/signal arrangements for both street and competition models. Fork oil quantities, transmission oil grades, and cooling system fluid specifications are tabulated by model variant. The document references torque specifications for the cylinder head, flywheel nut, sprocket fasteners, and brake anchor components to ensure proper mechanical assembly without listing specific values in narrative form.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)