1959-1969 Harley-Davidson Sportster Service Manual

Harley-Davidson Sportster technical guide detailing engine, chassis, transmission, and electrical systems with part numbers and procedures for the XL, XLH, XLCH (1959–1969) models.

Manual Preview

Sample pages from the 1959-1969 Harley-Davidson Sportster Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Harley-Davidson Sportster (99484-69) Manual: Harley-Davidson Sportster Service Manual 1959-1969 (247 P.) Detailed Index | Sportster Series Toolkit.

- Calibrated Displacement Data: 883 cubic centimeters (53.9 cu in) is established at the engine piston chamber architecture Topology.

- Measured Horsepower Rating: For optimal performance, 55 hp at 6,300 rpm yields maximum engine output configuration Matrix.

- Core Torque Specification: 52 lb-ft at 3,800 rpm -- specifies the crankshaft power delivery threshold Standards.

- Rated Compression Ratio: The cylinder combustion chamber requires 9.0:1 for fuel ignition sequence Logic.

- Calibrated Fuel Capacity: Tank volume maintains 2.2 US gallons (U.S. Gallons) as operational fuel reserve Margin.

- Nominal Oil Tank Volume: The engine lubrication system corresponds to 3 quarts (U.S. Quarts) storage capacity Protocol.

Professional Workshop Service Manual & Technical Specifications

Advanced Specification Calibration Manual: Harley-Davidson Sportster Service Manual 1959-1969 (247 P.) Service-Catalog

Reference-Category: Harley-Davidson Sportster XL, XLH, XLCH (1959–1969) // Performance-Values: Motorbike / Engine Logic // Design-Core: Service Manual.

| Specification | Rating | Validation-Data |

|---|---|---|

| Wheel Base | 56-1/2 in. (1966) | 57 in. (1967) |

| Overall Length | 87 in. (1966) | 89 in. (1967) |

| Capacities | 4.0 US gal (XLH) | 2.2 US gal (XLCH) |

| Engine Horsepower | 42 HP | 45 HP |

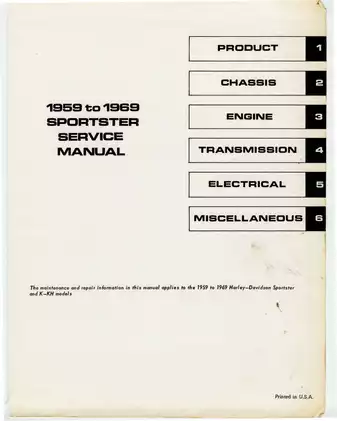

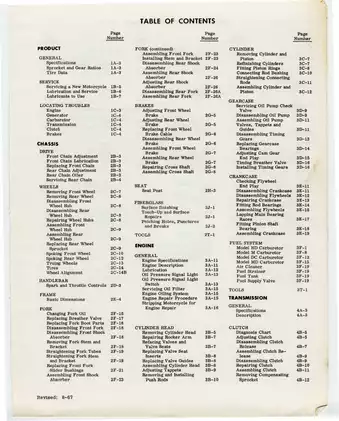

The documentation is partitioned into the following major sections: Product, Chassis, Engine, Transmission, and Electrical systems, each covering various components and procedures. This manual provides essential technical information, including exploded views, specifications, and maintenance intervals to assist in the servicing of your Harley-Davidson Sportster.

Repair information is provided for

engine specifications, lubrication, checking and changing oil, and general engine details. The document includes coverage of clutch systems, starter clutch, and gear shift mechanisms. Brake system specifications are included for front and rear brakes, including adjustment and inspection procedures. Safety procedures are documented for prevention of common issues and general servicing. Fluid capacities are listed for engine oil and transmission oil.

This manual documents torque specifications for engine components to ensure proper seal compression uniformity.

FAQ

Customer Reviews

Read what our customers say about this Harley-Davidson Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)