1999-2002 Suzuki SV650/S Service Manual (489 P.)

Wiring diagrams, specifications, and repair sequences for V-twin engine maintenance. Complete torque calibration data for cylinder head assembly and timing chain adjustment procedures included.

Manual Preview

Sample pages from the 1999-2002 Suzuki SV650/S Service Manual (489 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki SV650/S — 1999–2002 Advanced Systematic Documentation | SV650/S Series Repository.

- Verified Volume Data: Piston displacement reaches 645 cm³ (39.4 cu in) is established as the engine cylinder volume Bounds.

- Key Charge Quantity: For optimal performance, 16.0 L (4.2/3.5 US/Imp gal) fuel tank capacity is standardized to the fuel system Topology.

- Principal End Play: Drive chain 20-pitch length is specified at 319.4 mm (12.57 in) service limit Matrix.

- Advanced Cooling Specs: Engine coolant capacity reaches 1,600 ml (1.7/1.4 US/Imp qt) total solution capacity Standards.

- Defined Mass Specs: Dry mass is rated at 165 kg (363 lbs) for the complete motorcycle frame Margin.

- General Twist Specifications: Compression ratio represents 11.5:1 for standard combustion chamber pressure Protocol.

Professional Workshop Service Manual & Technical Specifications

Verified Operations Manual: Bike Detailed Suzuki SV650/S Repair Manual (1999-2002) Repair-Index

Conceptual-Layout: SV650/S (1999-2002) // Product-Line: Fuel system and transmission service information // Maintenance-Category: Engine and chassis performance data.

| Metric | Operational-Logic | Calibration-Standards |

|---|---|---|

| Engine Systems | Complete valve and combustion specifications | Service intervals documented |

| Transmission Assembly | Six-speed gear ratios with final drive reduction | Torque specifications provided |

| Cooling Circuit | Thermostat and radiator operation sequences | Temperature thresholds documented |

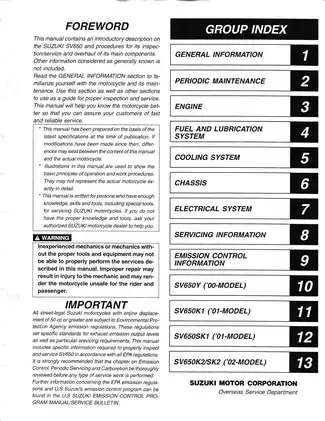

Engineering chapters address the front and rear cylinder heads, drive chain management, and clutch assembly, organizing fuel system procedures and suspension geometry. Repair procedures are structured around engine disassembly sequences, transmission service intervals, and electrical system diagnostics.

OEM guidelines are included for periodic maintenance scheduling across 1,000 to 24,000 kilometer intervals. Transmission service information covers six-speed constant mesh operation, gearshift fork clearances, and primary/final reduction specifications. HVAC system procedures are included for thermostat removal, water pump disassembly, and coolant circulation diagnostics. Technical specification data covers engine compression pressure, crankshaft journal clearances, and piston-to-cylinder tolerances. Parts identification is covered for valve springs, piston rings, and bearing assemblies.

The manual documents torque specifications for the engine sprocket nut to ensure proper rotational loosening prevention. Detailed chapters describe the charging system regulator function, starter motor disassembly procedures, and ignition system operation. Exploded diagrams present component arrangement for the front brake caliper, rear suspension linkage, and steering stem assembly. System-level information includes fuel pump vacuum operation, carburetor diaphragm and piston adjustment, and emission control circuit verification. Technical specifications table identifies compression pressure limits (1,100 kPa minimum), crankshaft thrust bearing clearance ranges (0.050-0.110 mm), and valve stem deflection service limits (0.35 mm maximum). The document includes complete valve seat cutter specifications, fork oil capacity measurements, and brake fluid type classification (DOT 4).

FAQ

Customer Reviews

Read what our customers say about this Suzuki Bike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)