2013 Polaris Scrambler XP 850 HO Service Manual

Technical reference spanning multiple variants of the Scrambler XP 850 HO, covering all essential maintenance and repair procedures. Includes part numbers and diagrams. PN A13GH85AJ.

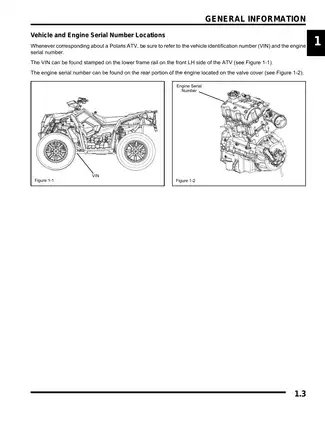

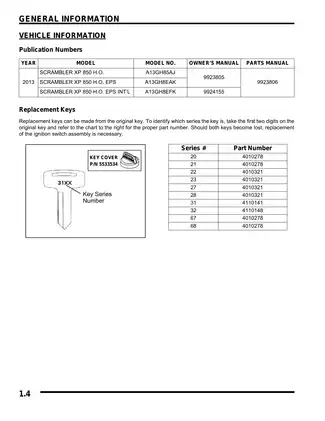

Manual Preview

Sample pages from the 2013 Polaris Scrambler XP 850 HO Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Functional Engineering Installation Manual: Polaris Scrambler XP 850 HO (2013) Overhaul-Reference Polaris Scrambler XP 850 HO / EPS / INT'L (A13GH8EAK / A13GH8EFK). Service Manual.

- System Specifications: 850 cc engine displacement optimizes power delivery for demanding terrain.

- Core Optical Resolution: 1200 dpi ensures clear and precise component identification in diagrams.

- Specific Fastener Torque: 47 ft-lbs for drive clutch retaining bolts ensures secure component attachment.

- Published Engine Oil: Polaris PS-4 Synthetic Engine Oil is recommended for optimal lubrication.

- Authorized Print Quality: 43 psi fuel pressure maintains consistent system operation.

- Calibrated Drivetrain Fluid: 37 oz. (1100 ml) AGL Gearcase Lubricant ensures proper drivetrain function.

Professional Workshop Service Manual & Technical Specifications

Functional Engineering Installation Manual: Polaris Scrambler XP 850 HO (2013) Overhaul-Reference

Year-Coverage: 2013 // Technical-Benchmarks: Engine and Drivetrain Specifications // Year-Coverage: 2013

| Identifier | System-Path | Calibration-Spec |

|---|---|---|

| Drive Clutch | Engine RPM | 7600 RPM |

| Drive Belt | Drive Belt Length | 105" |

| Driven Clutch | Spring Preload | 2.41" Front / 4.86" Rear |

| Transmission | Gear Ratio | Varies by Gear |

| Cooling System | System Capacity | 2 qts. (1.9 L) |

| Fuel System | Fuel Pressure | 43 psi +/- 3 psi |

Engineering chapters address

Engine Disassembly and Inspection

This section details the proper procedures for disassembling and inspecting key engine components, including the cylinder head, camshafts, and valves. It provides guidance on measuring critical dimensions and identifying wear to ensure optimal engine performance and longevity. Careful adherence to these procedures is vital for a successful rebuild.

Fuel System Troubleshooting

This chapter focuses on diagnosing and resolving issues within the electronic fuel injection (EFI) system. It covers common problems such as fuel starvation, rich or lean mixtures, and poor idle conditions. Technicians will find guidance on inspecting fuel lines, injectors, and the fuel pump to ensure proper fuel delivery and engine operation.

Cooling System Maintenance

Detailed procedures for maintaining the vehicle's cooling system are provided, including radiator cleaning, coolant checks, and water pump service. Emphasis is placed on proper coolant levels and the use of recommended antifreeze mixtures to prevent overheating and ensure efficient heat transfer. Attention is given to all hoses and connections to prevent leaks.

Transmission Service and Disassembly

This section outlines the steps for servicing the transmission, including removal, disassembly, and reassembly. It covers the inspection of all bearings, gear teeth, and shift components. Proper lubrication and torque specifications are emphasized to ensure the longevity and reliability of the transmission system.

Clutching (PVT) System Overview

An overview of the PVT system, including the drive clutch, driven clutch, and drive belt, is presented. This chapter explains the operation of these components and their role in engagement, upshift, and backshift. It also provides essential maintenance and inspection guidelines to ensure maximum performance and service life of the PVT system.

...documents torque specifications for various engine and transmission components to ensure proper service interval reliability.

FAQ

Customer Reviews

Read what our customers say about this Polaris ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)