Cub Cadet Series 7000 M4 7360SS Compact Tractor Service Manual (170 P.)

Covers engine overhaul, transmission disassembly, hydraulic systems & differential diagnostics. Factory repair procedures including compression testing, injection timing, and component assembly torque specs.

Manual Preview

Sample pages from the Cub Cadet Series 7000 M4 7360SS Compact Tractor Service Manual (170 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Cub Cadet M4 7360SS — 1996–2005 Mechanical Industrial Digest for Series 7000 Binder.

- Engineered Wattage Specs: Engine oil capacity is configured at 4.5 liters (4.8 US quarts) Requirements.

- Calibrated Generation Capacity: For hydraulic operation, 43 liters (45.9 US quarts) limits the transmission and fluid reservoir Threshold.

- Measured Burn-in Temperature: Cooling system volume is set to 7.1 liters (7.9 US quarts) Mapping.

- Standard Enclosure Specs: The fuel tank requires 35 liters (9.2 US gallons) for operational range Configuration.

- Prescribed Fastener Specs: Valve clearance represents 0.25 mm (0.0098 inches) cold setting Benchmarks.

- Verified Electrical Specs: Alternator output is measured at 50 amperes nominal charging capacity Range.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Maintenance Workshop Manual: Cub Cadet Series 7000 M4 7360SS Compact Tractor Service Manual Knowledge-Base

Diagnostic-Area: Cub Cadet M4 7360SS, 7192–7305, 7530–7532 // System-Coverage: Engine assembly, Transmission operation, Hydraulic systems Logic // Application-Range: Diesel compact tractor service documentation for comprehensive overhaul and component replacement.

| Component | Parameters | Calibration-Standards |

|---|---|---|

| Engine Block | Cylinder bore, compression pressure, crankshaft runout | Documented with measurement procedures |

| Fuel Injection System | Nozzle pressure, injection timing, delivery valve specifications | Complete calibration standards provided |

| Transmission Assembly | Gear backlash, shaft end play, synchronizer clearance | See Chapters 6-7 for detailed specifications |

| Hydraulic System | Pump pressure relief settings, cylinder clearances, valve neutral position | Comprehensive service standards included |

| Steering System | Toe-in adjustment, wheel free play, cylinder rod dimensions | Reference data for field adjustment |

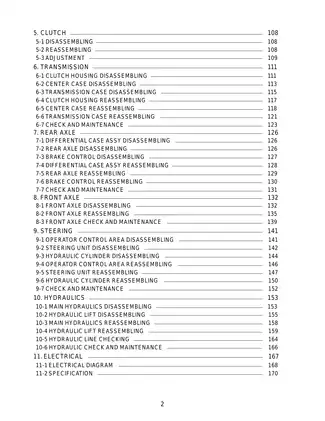

Service procedures are grouped by engine overhaul protocols, transmission disassembly sequences, rear axle differential assembly, front axle component removal, steering unit reconstruction, and hydraulic system maintenance. The document encompasses cylinder head valve mechanism inspection, timing gear and flywheel reassembly, crankshaft bearing clearance measurement, cooling system thermostat replacement, fuel injection nozzle testing, electrical starter motor inspection, alternator charging system diagnosis, clutch assembly and adjustment, transmission housing reassembly, differential case assembly, front axle knuckle arm repair, steering hydraulic cylinder installation, and hydraulic lift control linkage configuration.

Adjustment procedures are detailed for valve clearance settings when the engine is cold, fuel injection timing using delivery valve removal methods, and idler speed configuration via governor control. Timing procedures are documented for crankshaft positioning relative to top dead center compression stroke, injection pump shim thickness selection, and nozzle opening pressure washer adjustment. Technical notes are provided for lubrication oil filter replacement, pressure relief valve spring adjustment, and oil seal installation with specified depth requirements. Quality checks are addressed for compression pressure measurement across all cylinders, piston ring end gap clearance, connecting rod thrust clearance verification, and main bearing journal clearance inspection. The manual documents torque specifications for engine mounting bolts to ensure proper fastener fatigue prevention.

Electrical Specifications: System type 12-volt negative ground; Battery capacity 500 CCA; Alternator output 50 ampere; Starter motor 2 kilowatt with solenoid switch; Headlamp 35 watts; Panel lamp 3.4 watts.

Capacities Reference: Engine oil with filter change 4.5 liters; Cooling system 7.1 liters; Transmission and hydraulic fluid 43 liters; Rear axle lubricant 6.5 liters; Fuel tank 35 liters.

The 174-page manual includes detailed disassembly sequences for all major assemblies, comprehensive inspection criteria for wear limits and clearance specifications, step-by-step reassembly procedures with torque value charts, and troubleshooting flowcharts for fuel knock, overheating, exhaust smoke, idle speed variation, power loss, and starting system faults. Wiring diagrams, component identification illustrations, and assembly cross-section drawings support the technical content throughout. Special tools referenced include compression gauge adaptor, piston pin setting tool, camshaft bushing installer, and oil pressure switch socket wrench, with complete part numbers for each specialized equipment requirement.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)