SHARP SF-7320 / SF-7370 Copier Service Manual (80 P.)

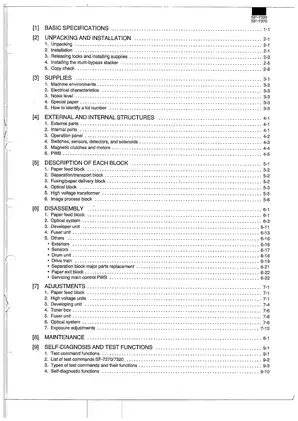

Diagnostic procedures and component service for SF-7320/SF-7370 copiers. Covers paper feed, optical system, fuser unit, and developer assembly with detailed disassembly and adjustment protocols.

Manual Preview

Sample pages from the SHARP SF-7320 / SF-7370 Copier Service Manual (80 P.) manual

Purchase & Download

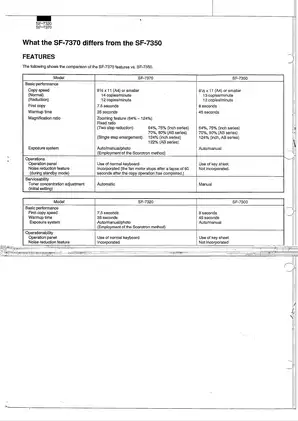

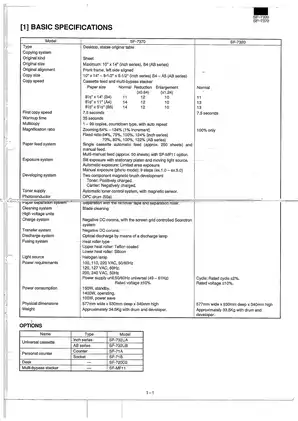

Models Covered & Key Technical Specifications

SHARP SF-7320 & SF-7370 Copier — 1990s

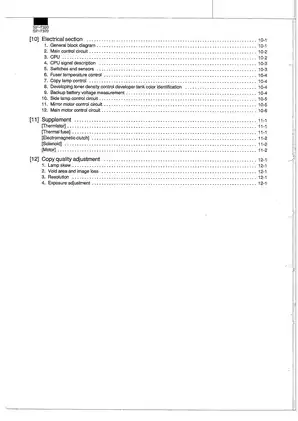

Integrated Documentation Catalog | SF-7320/7370 Series Archive.

- Design Output Performance: 14 copies/minute is designed for the normal cassette feed rate capability Architecture.

- Calibrated Linear Velocity: For first copy production, 7.5 seconds delivers the initial output timing response Standards.

- Advanced Gross Dimensions: The original size maximum requires 10" × 14" (B4 metric) — establishes the input document boundary Specifications.

- Standard Rotational Force: The transfer corona unit is configured at 18.0 ± 3 nA (MHVG output current) for charge deposition Matrix.

- Principal Play Limits: Side margin void area is measured at 5 to 8 mm (lead edge tolerance range) Limits.

- Key Burn-in Temperature: Upper heat roller surface maintains 180 degrees Celsius — establishes the fusing thermal protocol Envelope.

Professional Workshop Service Manual & Technical Specifications

Multi-System Calibration Parts Manual: SHARP SF-7320 & SF-7370 Copier Maintenance & Repair Manual - Comprehensive Diagnostics and Service Procedures Data-Compendium

Model-Portfolio: SHARP SF-7320, SHARP SF-7370 // Assembly-Group: Optical systems / Electromechanical modules Logic // Model-Portfolio: High voltage transformer units, developing systems, fusing mechanisms.

| Component | Baseline | Calibration-Standards |

|---|---|---|

| Paper feed system | Single cassette + manual feed | Documented specifications for feed rates |

| Optical block | Mirror-based slit exposure | Complete calibration procedures included |

| Fusing system | Heat roller temperature control | Temperature thresholds and thermistor values documented |

| Developer unit | Two-component magnetic brush | Toner concentration sensor adjustment data provided |

| Image process | OPC drum with charge layers | Voltage potential reference values included |

The repository is divided into technical chapters addressing paper feed mechanisms, separation and transport systems, fusing block operations, optical exposure pathways, high voltage transformer operations, and image processing cycles. These chapters cover the complete service architecture alongside disassembly sequences, adjustment procedures, maintenance schedules, self-diagnostic functions, electrical schematics, and supplemental component specifications. The manual integrates operational theory, structural layouts, connector identification, sensor configurations, and troubleshooting logic.

Installation guidelines are provided for the SF-7320 and SF-7370 copier models, including unpacking procedures, environmental requirements, machine positioning on level surfaces, and power source specifications. The document references proper environmental conditions (20–25°C, 65–45% RH nominal) and notes the relationship between temperature and humidity settings for optimal performance. Maintenance guidelines are included for the developer unit, featuring removal techniques for the toner hopper, MG roller configuration, and DV blade replacement every 120,000 copies. OEM guidelines are included for disassembly operations across the paper feed block, optical system components, fuser unit sections, and drum-related assemblies, with detailed precautions regarding corona wire handling, lens carriage positioning, and bearing installation. Transmission service information covers the mirror base drive wire tensioning, lens position sensor alignment, and stepping motor configuration for magnification adjustment on the SF-7370 model. HVAC system procedures are included for thermal management within the fuser block, documenting the thermistor installation, thermostat clearance verification, and heater lamp replacement protocols.

The manual documents torque specifications for optical system components to ensure proper mechanical alignment and stable operational geometry.

The document provides electrical schematics detailing the main control circuit architecture, CPU signal descriptions, power supply pathways, copy lamp control circuits, fuser temperature regulation, developing toner density monitoring, side lamp control for the SF-7370, mirror motor regulation, and main motor synchronization. Switches, sensors, detectors, and solenoid function descriptions are integrated throughout, alongside troubleshooting status codes (mirror base feed trouble L1, mirror base return trouble L3, magnification error L6, heat roller thermistor failure H2, memory backup voltage U1, AE sensor malfunction U3). The supplement section addresses thermistor operation principles, thermal fuse construction varieties, electromagnetic clutch mechanics, solenoid conversion systems, motor speed detection methodologies using photo encoders and rotary encoders, and bridge servo voltage regulation techniques. Copy quality adjustment procedures document image skew tolerances (1.5mm maximum), void area specifications (5–8mm side margin), lead edge image loss limits (2.5–11.5mm), resolution verification across normal, enlargement, and reduction magnification modes, and exposure density calibration using the Sharp gray chart reference standard.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)