2004 Sharp AR-168S/D Digital Multifunctional Service Manual (185 P.)

Covers AR-168S/AR-168D copier units with procedures for drum replacement, charger maintenance, optical calibration, and fusing control. Ref: 00ZAR168D/A1E

Manual Preview

Sample pages from the 2004 Sharp AR-168S/D Digital Multifunctional Service Manual (185 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sharp AR-168S, AR-168D Digital Multifunctional System — 2004 Analytical Resource Documentation | AR-168 Series Division.

- Published Rotational Force: Heat roller surface temperature requires 165–190°C for standard fusing operation Threshold.

- Specific Storage Capacity: For hydraulic operation, 17 L (4.5 gal) dictates the transaxle capacity Standards.

- Integral Fit Tolerances: Intake valve gap corresponds to 0.20 mm (0.008 in) cold lash setting Matrix.

- Operational Climate Specs: Maximum rated current yields 8 A at 120 V AC standard power supply Margin.

- Fundamental Travel Rate: Maximum throughput reaches 16 ppm (Letter size paper feed) Protocol.

- Universal Clamp Forces: Main charger grid bias is set to 580 ± 12 V output voltage Architecture.

Professional Workshop Service Manual & Technical Specifications

Thorough Overhaul Wiring Manual: Copier Sharp AR-168S/D Digital Multifunctional System Service Manual (188 P.) Chassis-Documentation

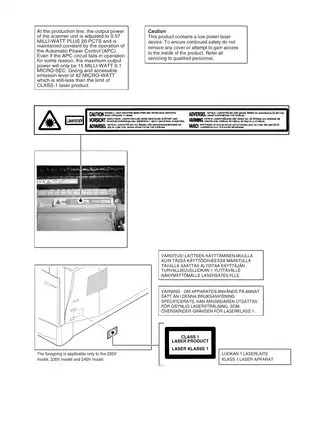

Model-Portfolio: Sharp AR-168S, AR-168D (00ZAR168D/A1E) // Subsystem-Focus: Digital Multifunctional / Electrostatic Copy Logic // Coverage-Scope: 600 dpi resolution, 800 W heater lamp, 165–190°C fusing operation.

| Metric | Technical-Path | Context |

|---|---|---|

| Specifications | Basic operational parameters | Documented across Chapter 2 with complete machine dimensions 518mm(W) × 503mm(D) × 380mm(H) |

| Copy Process | Electrostatic imaging workflow | Complete specifications provided including OPC drum structure and laser wavelength 770-795nm |

| Disassembly Procedures | Component-level service access | Documented for high voltage, optical, fusing, and paper transport sections |

| Circuit Diagrams | Electrical system architecture | Complete wiring documentation provided in Chapter 14 with MCU, operation, and power supply schematics |

| Adjustments | Calibration and alignment procedures | Documented procedures for optical magnification, copy density, and high voltage settings |

| Test Commands | Diagnostic access protocols | Complete command reference provided with trouble code definitions |

Systematizing the service groups into adjustments configures operational descriptions, details copy process, references test command procedures, and establishes maintenance alongside electrical section analysis.

Wear limits are specified for the developing unit with 250K page cycle and drum kit rated at 25K impressions within the consumable parts inventory. The documentation addresses OPC drum layer construction with 20 micron thickness specifications and aluminum base composition for the photoconductive element. Assembly instructions are detailed for transfer charger unit removal requiring release of front and side cabinet assemblies before accessing internal high voltage components. System operation descriptions cover scanner section mechanisms including optical unit with 3-line CCD sensor configuration and CCFL white lamp illumination at 2.8W consumption. The manual provides torque specifications for fastener assemblies to ensure proper dynamic load distribution throughout mechanical subsystems.

Document sections reference fusing temperature control circuitry with thermistor-based monitoring achieving surface temperature regulation between 165-190°C during standard operation modes. Complete operational flow documentation spans paper feed mechanisms supporting tray capacity of 250 sheets with universal-type cassette and front-loading access configuration. Reversing tray operations for AR-168D duplex models include transport path descriptions with switchback functionality enabling two-sided document processing at 5.2 copies per minute. External interface specifications include USB 2.0 connectivity with shielded twisted pair cabling and IEEE 1284 bi-directional parallel port supporting 36-pin configuration for data transfer operations.

Test command reference tables provide access to mirror scan verification, SPF motor operation checks, and polygon motor lock detection protocols through numeric key entry sequences. Maintenance cycle settings allow selection among 3,000 to 25,000 sheet intervals with counter displays tracking total pages, developer consumption, and drum cartridge utilization across service intervals. Circuit diagram section spans MCU board architecture with H8S/2321 CPU peripheral connections, ASIC image processing pathways with HG73C114HF controller, and SDRAM memory interface supporting 8MB to 128MB capacity configurations.

Installation procedures document protective packing material removal including scan head locking switch release and developer unit insertion with magnetic roller distribution requirements. Unpacking sequences reference toner cartridge shaking protocols and cushion extraction from transport packaging before operational deployment. Paper loading specifications define front guide slide-type adjustment and left guide insert-type positioning to accommodate A4, B5, Letter, and Legal size media within maximum height indicators.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)