2000 Sharp AR-151/AR-156/AR-F152 Digital Copier Service Manual (174 P.)

Disassembly procedures, circuit diagrams, and optical section calibration for 15 CPM digital copiers with 400 dpi CCD scanning. PN: 00ZARF152/A1E

Manual Preview

Sample pages from the 2000 Sharp AR-151/AR-156/AR-F152 Digital Copier Service Manual (174 P.) manual

Purchase & Download

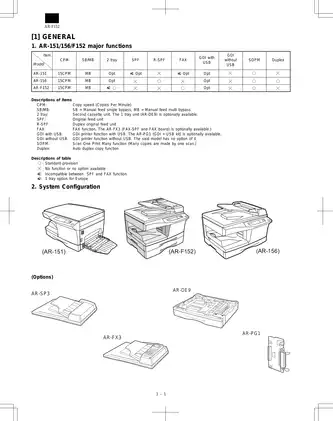

Models Covered & Key Technical Specifications

SHARP AR-151, AR-156, AR-F152 — 2000 Consolidated Engineering Blueprint | AR Series Collection.

- Reference Holding Capacity: 250 sheets is set to the cassette tray capacity Mapping.

- Integral Measurement Bounds: For optimal resolution, 400 dpi defines the CCD sensor scanning specification Configuration.

- General Circuit Specs: 800 W — is standardized to the heater lamp power requirement Benchmarks.

- Certified RPM Specs: Maximum engine speed corresponds to 3200 rpm Range.

- Factory Installation Footprint: Weight yields 19 kg (AR-151 with drum cartridges) Sequences.

- Established Charge Quantity: Heat roller temperature is established at 165°C–190°C for fusing operation Baseline.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Service Manual: Sharp AR-151, AR-156, AR-F152 Digital Copier Reference-Archive

Model-Portfolio: AR-151, AR-156, AR-F152 // Reference-Category: Digital Copier / Electrostatic Logic // Maintenance-Category: Complete service specifications documented.

| Technical Domain | System Component | Documentation Status |

|---|---|---|

| Document Overview | Operational Sections | Complete specifications provided |

| Engine Systems | Copy Speed Configuration | 15 CPM documented |

| Thermal Management | Heat Roller Temperature | 165°C–190°C range specified |

| Optical Resolution | CCD Sensor Capacity | 400 dpi scanning documented |

| Memory Architecture | Image Storage | 2 MB capacity specified |

Repair data is categorized into General specifications, Consumable Parts, External Views and Internal Structures, Unpacking and Installation, Operational Descriptions, Disassembly and Assembly, Adjustments, Simulation and Trouble Codes, User Program, Maintenance, Electrical Section, and Circuit Diagram, addressing 174-page service documentation for professional technicians.

OEM specifications cover the developing bias voltage control circuit, main charger grid adjustment procedures, transfer charger output regulation, and toner motor aging verification processes. The documentation addresses complete electrostatic image formation systems including charging, transfer, separation, and developing mechanisms. Assembly instructions are detailed for drum replacement procedures, charger wire cleaning protocols, and fusing unit maintenance operations. System operation descriptions cover scanner unit functionality with xenon lamp exposure, CCD sensor processing at 400 dpi resolution, and laser unit writing mechanisms. Wear limits are specified for developer cartridge lifecycles, OPC drum service intervals, and consumable part replacement schedules.

The manual provides torque specifications for fusing unit components to ensure proper heat roller assembly integrity. Hydraulic schematics are included for paper transport mechanisms coordinating resist roller solenoid timing, paper feed clutch engagement sequences, and duplex mode reversal operations. Technical documentation includes complete PWB unit layouts identifying exposure lamp inverter control, main MCU processing architecture, FAX control integration (AR-F152), LSU motor drive circuits, and power supply voltage regulation. Electrical section references cover high voltage adjustment procedures, copy density calibration methods, and communication section diagnostics for FAX-equipped models.

Detailed specifications document paper feed capacity ranges from 250-sheet cassette systems to 50-sheet multi-bypass configurations, operating temperature envelopes between 10°C–30°C, and first copy time benchmarks achieving 9.6 seconds for A4 tray delivery. Simulation mode entries enable diagnostic testing through 67 numbered procedures including optical system checks, SPF motor verification, aging cycles, and sensor operation validation. Maintenance intervals specify developer replacement at 25K cycles, drum cartridge service at 18K impressions, and systematic cleaning protocols for optical components. Circuit diagram documentation encompasses 13 detailed schematic pages mapping MCU processor interfaces, ASIC control logic, motor drive arrays, sensor input multiplexing, and power distribution networks across both copier and FAX subsystems.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)