Ricoh Aficio SP C3800 Service Manual (293 P.)

Ricoh Aficio SP C3800 technical guide detailing comprehensive service procedures. Complete coverage of maintenance, troubleshooting, repair sequences and component specifications. Essential reference for authorized technicians.

Manual Preview

Sample pages from the Ricoh Aficio SP C3800 Service Manual (293 P.) manual

Purchase & Download

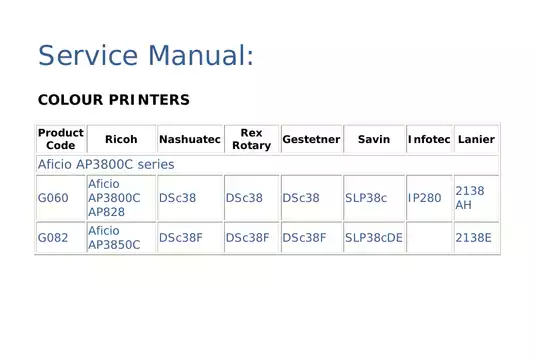

Models Covered & Key Technical Specifications

Ricoh Aficio AP3800C Series, Aficio AP3850C — 2001 Precision Technical Blueprint | AP3800C Series Repository.

- System Fill Specifications: 120 V, 60 Hz supply requires minimum 10 amperes is standardized to proper electrical installation Benchmarks.

- Core Deviation Limits: 220 V–240 V, 50 Hz/60 Hz configuration achieves permissible voltage fluctuation of ±10% Range.

- Specific Load Capacity: The machine installation elevation is calibrated to 2,500 m (8,200 ft) above sea level maximum operating altitude Sequences.

- Critical Cycle Rate: Polygon mirror motor operates at 21,850 rpm for B/W 600 dpi mode, increasing to 29,528 rpm for color processing is rated at high-speed beam writing Baseline.

- Universal Package Size: Transfer belt system achieves 125 mm/s color process speed at 1,200 × 1,200 dpi resolution, supporting 28 ppm full-color output Requirements.

- Calibrated Containment Volume: Development unit hopper capacity reaches 280 grams of toner developer per color chamber, sustaining continuous image production cycles Threshold.

Professional Workshop Service Manual & Technical Specifications

Commercial Hydraulic Manual: Printer 2001 Ricoh Aficio SP C3800 Technical-Briefing

Architecture-Focus: Aficio SP C3800 (2001) // Application-Range: Multifunction Color Printing Systems / Electrophotographic Technology Logic // Architecture-Focus: Four-Color Laser Exposure with Process Control Integration.

| System Component | Documentation Scope | Reference Details |

|---|---|---|

| Laser Exposure Module | Polygon mirror motor, synchronizing detectors, dual beam writing mechanism | Chapter 6.3 provides complete optical path and frequency adjustment data |

| Photoconductor Assembly | Four independent OPC drums with charge, development, and cleaning systems | Includes drum specifications and waste toner collection procedures |

| Fusing System | Belt-based heating with oil supply and temperature monitoring | Temperature specifications and energy saver mode configuration documented |

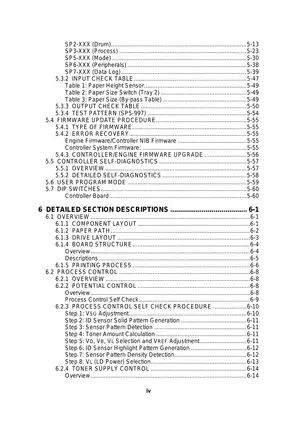

Organized into dedicated modules for Installation procedures including environment specifications and power requirements, Preventive Maintenance covering user-level and service-level component replacement cycles, and Replacement and Adjustment protocols addressing image registration, color shifts, and exterior cover removal. The document discusses Image development systems encompassing charge bias control, development unit operation, and toner supply mechanisms, while also exploring Process control methodologies including potential control self-check procedures and toner density feedback loops. Paper Feed systems receive extensive treatment with mechanisms for tray lift, size detection, and registration roller operation. Transfer and Paper Separation mechanisms are documented for belt contact, cleaning procedures, and image transfer current adjustment. Fusing technology receives detailed coverage spanning heating roller thermistor management, pressure roller fusing lamp operation, and oil supply unit detection. Troubleshooting guidance addresses service call conditions, process control error interpretation, and electrical component defect diagnosis.

The manual provides comprehensive coverage of the laser optical path, including F-theta lens correction and WTL (wavefront compensating lens) specifications. Wiring diagram references are included for the LD safety switch relay circuit and controller board layout. The document describes torque specifications for bolt attachment of various assemblies to ensure proper mechanical integration and prevent component separation during operation.

This service manual documents the complete mechanical, optical, and electrical architecture of the Aficio SP C3800 color printing system, including control parameter tables, signal flow diagrams, and preventive maintenance schedules. Extensive SP mode (service parameter) tables enable field technician configuration of process control thresholds, temperature profiles, and motor speed compensation values. The manual includes self-diagnostic procedures for the controller and engine firmware, along with firmware update protocols using IC card technology. Detailed section descriptions provide system overviews, drive layout diagrams, and board structure references for the controller and BCU (Base Engine Control Unit). The document covers optional peripheral equipment including duplex units, paper feed units, two-tray finishers, large capacity trays, four-bin mailboxes, and IEEE1394 interface boards, each with dedicated replacement and adjustment procedures. Jam detection logic, paper overflow detection thresholds, and error recovery procedures are documented for all paper handling sections. The specification section provides general machine specifications, supported paper sizes, software accessories, and optional equipment compatibility matrices.

FAQ

Customer Reviews

Read what our customers say about this Ricoh Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)