2007 Ricoh D014/D015 (MPC 6000 and MPC 7500) Copiers Service Manual

Official Service and Repair Manual for Ricoh D014/D015 MPC 6000/7500 Copiers. Comprehensive coverage for troubleshooting and maintenance, including part numbers and diagrams. PN D014/D015

Manual Preview

Sample pages from the 2007 Ricoh D014/D015 (MPC 6000 and MPC 7500) Copiers Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ricoh D014/D015 (MPC 6000 and MPC 7500) Copiers Service Manual - 2007 Professional Copier Sourcebook | Series Copier Archive. • Design Specification: Machine Code D014/D015 corresponds to Primary identification designation. • Advanced Specification: Year is 2007 determines Model year of manufacture. • Calibrated Specification: File Size is 15.91 MB is calibrated to Digital document size. • Documented Specification: Pages is 853 defines Total document page count. • Prescribed Specification: Language is English dictates Primary language of content. • Engineered Specification: Category is Copier sets Equipment classification.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Instructional Overhaul Manual: Copier 2007 Ricoh D014/D015 (MPC 6000 and MPC 7500) Copiers - Comprehensive Service & Repair Guide Field-Reference

Serial-Range: D014 / D015 (2007 Edition) // Specification-Class: Copier / System Logic // Operational-Framework: Comprehensive Service & Repair Guide

| Specification | Diagnostic-Logic | Context |

|---|---|---|

| Machine Code | D014/D015 | Primary identification designation |

| Year | 2007 | Model year of manufacture |

| File Size | 15.91 MB | Digital document size |

| Pages | 853 | Total document page count |

| Language | English | Primary language of content |

| Category | Copier | Equipment classification |

TABLE OF CONTENTS

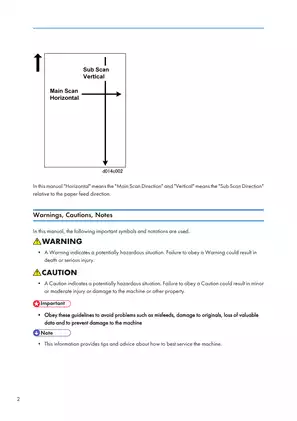

- Conventions

- Warnings, Cautions, Notes

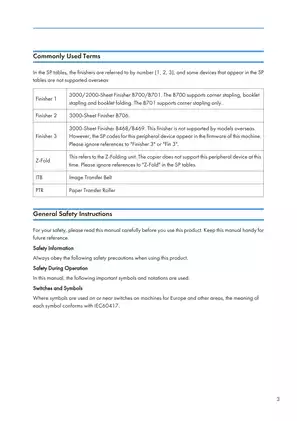

- Commonly Used Terms

- General Safety Instructions

- Responsibilities of the Customer Engineer

- Before Installation, Maintenance

- During Maintenance

- After Installation, Servicing

- Special Safety Instructions for Toner

- Safety Instructions for this Machine

- New Features of D014/D015

- Responses to Requests for Improvement

- Image Quality Improvement

- Comparison of Changes in Basic Operation

- System Configuration and New Options

- More Details About Design Changes

- Small Changes

- Notes About Servicing

- Detailed Summary of Changes

-

- Installation

- Copier D014/D015 Accessories

- Copy Tray (B756) Accessories

- A3/11" X 17" Paper Size Tray (B331) Accessories

- Counters Accessories

- LCT (B473), LCT Adapter (B699) Accessories

- LG Unit for A4/LT LCT (B474) Accessories

- LCIT RT4000 (D350) Accessories

- 2000/3000 Sheet Finishers (D373/D374) Accessories

- Punch Unit (B702) Accessories

- Output Jogger Unit (B703) Accessories

- Mail Box (B762) Accessories

- 3000-Sheet Finisher (B830), Finisher Adapter (D375) Accessories

- Punch Unit B831 Accessories

- Cover Interposer Tray (B704) Accessories

- Cover Interposer Tray CI5000 (B835) Accessories

- Z-Folding Unit ZF4000 (B660) Accessories

-

- Preventive Maintenance

-

- Replacement and Adjustment

-

- Troubleshooting

-

- Service Tables

-

- Details

-

- Specifications

Technical content addresses system configuration, new options, and detailed summaries of changes for the D014/D015 series. Key sections cover installation requirements, copier and peripherals configurations, and various accessory options. It also details preventive maintenance procedures, replacement and adjustment guidelines for major components like the drum and PCU, and comprehensive troubleshooting with SC codes. The manual concludes with detailed specifications and operational overviews, offering a complete reference for service engineers. Troubleshooting coverage is extensive, including SC codes for scanning, image development, paper feed, and device communication. The manual also details specific service tables and troubleshooting procedures for common issues, ensuring thorough support for the D014/D015 model series.

Systematically demanding installation procedures are thoroughly documented, covering everything from operating environment requirements to the connection of various peripheral devices. The manual details the setup for multiple system configurations, including options for copy trays, counter brackets, and large capacity trays (LCTs). Specific instructions are provided for installing finishers, punch units, jogger units, mailboxes, and cover interposer trays, ensuring correct assembly and functionality. The process for updating firmware and configuring specific settings like staple supply names and paper size detection are clearly outlined, facilitating optimal machine performance. Maintenance and troubleshooting sections offer guidance on common issues, replacement procedures for key components, and diagnostic codes, providing a complete support solution for service technicians. Detailed explanations of design changes, small adjustments, and notes about servicing ensure users are aware of the latest improvements and best practices for maintaining the D014/D015 copier series.

Torque Statement: Documents torque specifications for components to ensure proper cyclic stress resistance.

FAQ

Customer Reviews

Read what our customers say about this Ricoh Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)