Sharp SD-2260 Copier Service Manual (256 P.)

Maintenance procedures, optical section tuning, and duplex copying diagnostics for Sharp SD-2260. Covers toner concentration control, image forming adjustments, and RADF system setup. Reference 00ZSD2260SME1

Manual Preview

Sample pages from the Sharp SD-2260 Copier Service Manual (256 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sharp SD-2260 — 1990s Structured Directory for SD-2260 Series Library.

- Factory Native Resolution Data: 5.0 lines/mm is standardized to the copy center output Range.

- Certified Clamp Forces: For proper fusing operation, 250 N·m corresponds to the upper separation pawl life Sequences.

- Engineered Fluid Levels: The waste toner bottle capacity reaches 1750 g (125K with 6% density originals) Baseline.

- Primary Wattage Specs: Japan 15A specification main heater is rated at 750 W maximum power consumption Requirements.

- General Cold Start Limits: Warm-up time achieves approximately 10 minutes (15A specification) or about 5 minutes (20A specification) Threshold.

- Integral Scan Resolution: Copy magnification ratio setting achieves ±0.9% accuracy with fixed ratios including 200/141/122/115/100/86/81/70/50 percent

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Troubleshooting Repair Manual: Official Sharp SD-2260 Copier Service Manual - Comprehensive Maintenance & Troubleshooting Guide Technical-Repository

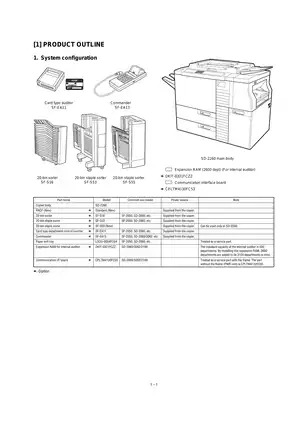

Model-Portfolio: SD-2260 copier systems and compatible options // Year-Coverage: Multi-region operational specifications covering Japan, Europe, USA, Canada, Australia, and export markets // Calibration-Scope: Electrical adjustments, mechanical alignments, and sensor calibration procedures documented.

| Integrated-Framework | Baseline | Calibration-Data |

|---|---|---|

| Paper Feed Systems | Roller, air pressure, and automatic feed mechanisms | Complete operational ranges and adjustment procedures included |

| Image Forming & Optical Sections | Charger units, OPC drum, developing, fusing assemblies | Voltage outputs, sensor sensitivities, and alignment specifications documented |

| Process Control | Main charger grid voltage, transfer/separation charger circuits | Threshold levels, correction modes, and monitoring parameters provided |

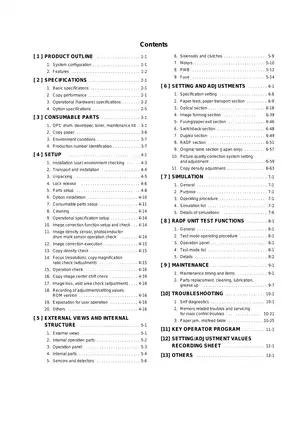

The repository is divided into thirteen comprehensive sections covering system configuration, specifications, consumable parts identification, installation procedures, and troubleshooting protocols. The manual addresses paper feed and transport mechanisms, optical section adjustments, image forming unit operations, fusing system parameters, duplex copying functionality, RADF unit control, original table systems, and picture quality correction operations. Sections also encompass simulation test modes, sensor and detector operations, maintenance timing schedules, and communication interface specifications for multi-region deployments.

Analytically mandating systematic service procedures, the manual provides detailed reference material for the scanner unit, optical mirrors and lenses, photoconductor drum operations, cleaner blade positioning, and developing roller main electrode alignment. Installation guidelines are provided for optional accessories including sorters, staple units, auditors, and expansion memory modules. Maintenance guidelines are included for cleaning procedures, lubrication points, and fusing section component care. OEM guidelines are included for consumable parts including toner cartridges, developer concentrate, OPC drums, and waste toner collection systems, each with production identification codes and compatibility matrices. Transmission service information covers paper transport timing, clutch and solenoid operations, belt tension adjustments, and paper stopper positioning across all operational modes. HVAC system procedures are included for fan motor operations, air pressure validation, blower valve positioning, and suction system calibration.

The document includes torque specifications for the fusing roller pressure assembly to ensure proper mechanical engagement. Electrical adjustment simulations are documented for copy magnification ratio correction, focus positioning across normal and specialty modes, image density sensing, and sensor threshold calibration. Sensor and detector specifications cover the original table glass area, RADF transport path, duplex section alignment, and paper path sensors with their associated control circuits. Wiring diagram data is provided for main control PWB interfaces, high voltage power distribution, AC/DC power conversion, and auditor communication protocols. The manual documents the process control sensor output levels, OPC drum mark sensor sensitivity ranges, image density reference values, and automatic correction procedures activated during machine warm-up cycles.

Operation test modes enable field verification of scanner motor function, lens carriage positioning, color lamp application voltage, discharge lamp and blank lamp operations, developing unit rotation, toner concentration sensing, paper feed motor rpm verification, and transport roller clutch timing. Simulation procedures detail the paper empty detector judgment timing, paper resist force adjustment algorithms, duplex unit alignment plate stop positions, and RADF document stop position calibration for six distinct operating modes. The manual documents the fusing temperature settings for both single copy and duplex copy modes across different regional specifications, with separate parameters for Japan 15A, Japan 20A, and export configurations. Key operator program settings are mapped to enable user-configurable density levels, toner save function control, power save mode selection, and display language options based on destination specification codes.

Counter and maintenance records sections provide data clearing procedures for misfeed tracking, trouble event logging, OPC drum correction counters, developer usage cycles, and copy count accumulation per paper feed tray. Reference specifications include paper size detection sensor thresholds, paper width and length sensor calibration data, original size detection LED positioning, and document size sensor output level tables. The manual provides comprehensive troubleshooting self-diagnostic information, allowing service technicians to reference error code meanings, memory trouble cancellation procedures, communication interface troubleshooting, and paper feed tray failure diagnostics without performing repairs themselves.

Reference Structure: The document is organized as a complete technical repository with table of contents sections, detailed specification tables, simulation procedure guides, sensor and detector pinout diagrams, PWB location diagrams, electrical schematic references, and mechanical assembly drawings indicating component locations and access procedures.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)