2009 Sharp AR-C150 / AR-C250 / AR-C160 Service Manual (214 P.)

Covers AR-C150, AR-C160, and AR-C250 digital copiers with procedures for image process calibration, fusing control, transfer belt adjustment, and color balance optimization.

Manual Preview

Sample pages from the 2009 Sharp AR-C150 / AR-C250 / AR-C160 Service Manual (214 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sharp AR-C150/AR-C160/AR-C250 Digital Full Color Copier — 2009 Mechanical Industrial Sourcebook | Digital Copier Series Set.

- Measured Locking Torques: 113 N·m (83 lb-ft) is set to the blade cap screw fastening requirement Requirements.

- Established Containment Volume: For hydraulic operation, 17 L (4.5 gal) specifies the transaxle capacity Threshold.

- Factory Running Clearance: The intake valve requires 0.20 mm (0.008 in) cold lash setting Mapping.

- Approved Heat Tolerance: 15–35°C (59–95°F) yields the operational envelope limit Configuration.

- Reference Weight Data: The 42-inch model dictates 54.5 kg (120 lb) rated configuration Benchmarks.

- Critical Threaded Fastener Data: Maximum engine speed produces 3200 rpm calibrated guidelines Range.

Professional Workshop Service Manual & Technical Specifications

Multi-System Repair Calibration Manual: Copier 2009 Sharp AR-C150 / AR-C250 / AR-C160 Service Manual (214 P.) Transmission-Guide

Operational-Scope: Sharp AR-C150/C160/C250 digital copier models // Performance-Values: Color/Monochrome copy operations / Electrophotographic image processing logic // Product-Line: 600×600 dpi resolution, 15-25 ppm output specifications.

| Assessment-Parameter | Value | Architecture |

|---|---|---|

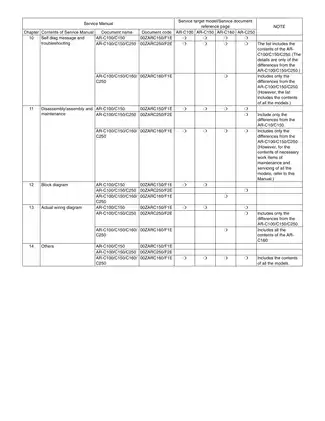

| Configuration Overview | 21 Chapters | Documented across scanner, image process, and fusing sections |

| Specifications Database | Engine/Optical/Control | Complete specifications provided |

| Consumable Parts Index | Developer/Toner/Drums | Replacement schedules documented |

| External/Internal Views | Assembly diagrams | See Chapter 5 |

| Machine Operations | Mode descriptions | Operating procedures documented |

| Setting and Adjustments | 25 adjustment procedures | Calibration references included |

| Simulation Diagnostics | Code system | Testing protocols documented |

| Self-Diagnosis Messages | Troubleshooting codes | Error resolution procedures |

| Maintenance/Disassembly | Component removal | Assembly sequences documented |

| Block Diagrams | System architecture | Chapter 12 |

| Wiring Charts | Actual wiring | Chapter 13 |

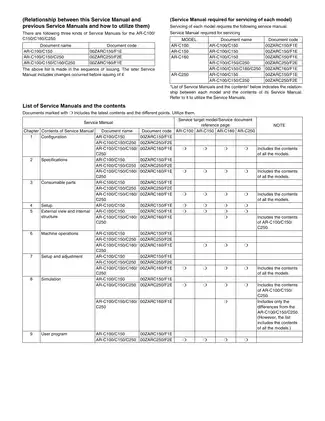

Documentation sections include configuration data establishing specifications, covering external view and internal structure, establishing machine operations, and describing setting and adjustments. The manual addresses simulation procedures, self-diagnosis message protocols, maintenance requirements, block diagram architecture, wiring chart documentation, and consumable parts compatibility data spanning developer units, toner cartridges, OPC drum assemblies, and transfer belt components.

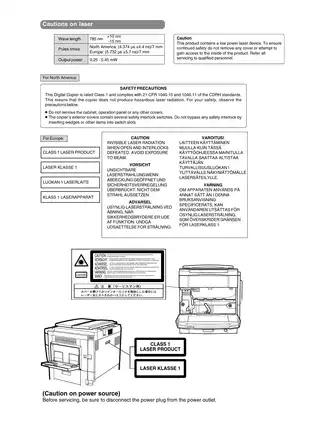

Technical content addresses the digital full-color copier architecture implementing 785nm laser scanning technology. The document provides scanner section specifications including CCD-based RGB image capture with 600dpi resolution in main and sub scanning directions. Image processing capabilities are documented through 256-gradation 8-bit signal conversion supporting color separation, area detection filtering, and dither pattern generation across multiple copy modes including Text/Photo, Printed Photo, Map, and Copy-of-Copy variants.

Torque specifications are documented for the fusing section components to ensure proper seal compression uniformity. Parts identification is covered for the optical scanning assembly, image forming stations, paper transport mechanisms, and electrical control boards. Removal procedures are documented for developer units, photoconductor drums, transfer belt assemblies, fusing rollers, and printed circuit board modules. Technical specifications are provided for main charger grid voltage adjustment, developing bias voltage calibration, transfer voltage optimization, and CCD gamma correction across normal document and copy document modes.

Factory specifications are documented for the AR-C150 15ppm model, AR-C160 16ppm model, and AR-C250 25ppm model variants. The manual includes adjustment procedures for DV doctor gap positioning, DV roller main pole alignment, toner concentration control reference levels, image density sensor calibration, photoconductor phase synchronization, and color registration in main and sub scanning directions. Simulation mode protocols enable diagnostic testing of optical scanning systems, paper transport clutches, fusing temperature control, developing motor operation, and transfer belt positioning mechanisms.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)