1999 Sharp AR-C150 / AR-C100 Series Service Manual (339 P.)

Covers AR-C150 digital full color copier with procedures for image scanning, transfer belt operation, and fusing assembly — includes 600 dpi resolution specs and 170°C heat roller calibration. Part 00ZARC150/F1E

Manual Preview

Sample pages from the 1999 Sharp AR-C150 / AR-C100 Series Service Manual (339 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sharp AR-C150 / AR-C100 Digital Full Color Copier (00ZARC150/F1E) — 1999 Professional Technical Archive | AR-C Series Unit.

- Prescribed Coupling Torques: 600 dpi is measured at the scanner resolution for both main and sub scanning directions Topology.

- Standard Twist Specifications: For optimal fusing operations, 170°C is set to the upper heat roller temperature during standard paper copying Bounds.

- Core Holding Capacity: The image scanner limits 117 mm/sec imaging speed across all document scanning modes Matrix.

- Rated Load Capacity: Maximum print output maintains 600 dpi horizontal and vertical resolution Norms.

- Technical Cycle Rate: Drum deflection cycle is established at 125.6 mm pitch for proper color registration alignment Margin.

- Advanced Torque Data: The machine's maximum power consumption controls 1800W during full-load printing operations Topology.

Professional Workshop Service Manual & Technical Specifications

Unified Safety Manual: Copier Sharp AR-C150 / AR-C100 Series Service Manual (339 P.) Wiring-Compendium

Technical-Scope: Sharp AR-C150 Series (00ZARC150/F1E) — 1999 // Application-Range: Color Copying / Photoconductor and Transfer Logic // Repair-Classification: 600 dpi scanner resolution, 170°C fusing limits, 117 mm/sec imaging speed specifications.

| Metric | System-Path | Architecture |

|---|---|---|

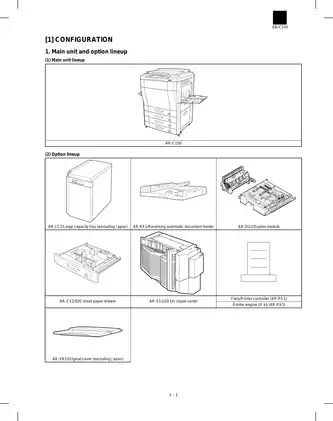

| Configuration and Specifications | Document structure across 22 chapters | Documented |

| Consumable Parts Lifecycle | Developer, toner, drum unit replacement intervals | Complete specifications provided |

| Setup and Installation Procedures | Environmental requirements and unpacking sequences | See Chapter 4 |

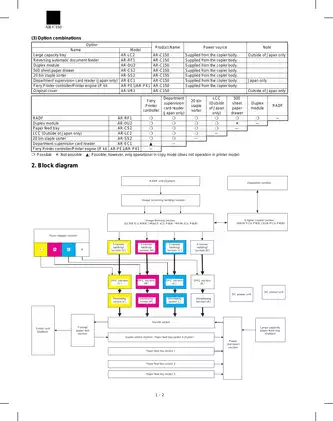

| External and Internal Components | Scanner, transfer, fusing, and paper transport assemblies | Documented |

| Simulation and Diagnostics | Code system for operation testing and adjustment | See Chapter 8 |

Maintenance information covers the document feed unit operation checks, assembles consumable parts installation guidance, references duplex module configuration options, addresses staple sorter bin specifications, and catalogs waste toner collection procedures.

Drivetrain specifications are addressed in the drive motor section documenting DC brushless motors for developing units, stepping motors for OPC drum positioning, synchronous motors for paper tray lift mechanisms, and electromagnetic clutches for transport roller control. The manual provides voltage adjustment procedures for main charger grid systems ranging from –200V to –900V default specifications, developing bias voltage controls set at –325V nominal levels, and transfer charger outputs varying between 1066V and 4000V depending on paper feed mode and color selection.

Reassembly procedures are specified for scanner unit parallelism adjustments, CCD lens positioning tolerances, fusing roller pressure calibration sequences, and transfer belt level compensation methods. Service intervals are documented for 40,000-sheet photoconductor replacement cycles, developer unit maintenance at identical 40,000-sheet intervals, and 80,000-sheet transfer belt renewal specifications. The document includes drum deflection cycle specifications reaching 125.6 mm pitch requirements for color registration alignment across yellow, magenta, cyan, and black imaging stations.

Component locations are identified for No. 2 and No. 3 mirror assemblies in the scanner reading section, LSU polygon motor units operating at 27,600 rpm for laser beam scanning, image density sensors positioned along the transfer belt pathway, and temperature thermistors monitoring fusing roller surface conditions between 125°C and 177°C operational ranges. Wiring diagrams and block schematics reference connections between ICU main PWB image processing boards, PCU PWB engine control circuits, high voltage power supply modules, and operation panel interface components.

Service procedures are documented for toner concentration reference level adjustments using SIM 25-2 diagnostic mode, CCD gamma calibration sequences with SIT chart UKOG-0280FCZZ, image density sensor gain optimization through automatic adjustment cycles, and photoconductor phase alignment compensating for 125.6mm drum circumference variations. The reference material documents torque specifications for the developing roller assembly mounting hardware to ensure proper thermal expansion compensation during extended operation cycles.

FAQ

Customer Reviews

Read what our customers say about this Sharp Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)