1992-1994 Suzuki GSX250F Service Manual (200 P.)

Engine specifications, tappet clearance, transmission gears, and brake torque values — 248cc DOHC 4-cylinder factory repair procedures PN: 99000-25010

Manual Preview

Sample pages from the 1992-1994 Suzuki GSX250F Service Manual (200 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki GSX250F, GSX250FWN, GSX250FP, GSX250FR (TM1500, TM1501, TM1502) — 1991–1994 Manufacturer Tactical Expert | GSX250F Series Repository.

- Established Power Rating: The piston displacement corresponds to 248 cm³ (15.1 cu in) as the engine cylinder volume Architecture.

- Operational Power Draw: For optimal performance, 12.56:1 is calibrated to the compression ratio specification Framework.

- Essential Thermal Rating: Engine idle speed sets 1,600 ± 100 r/min (revolutions per minute) as the operational baseline Norms.

- Baseline Unit Dimensions: The fuel tank capacity defines 12 L (3.2/2.6 US/Imp gal) including reserve fuel volume Bounds.

- Integral Bolt Torques: Battery voltage rating is specified as 12V 21.6 kC (6 Ah)/10HR for electrical system operation Topology.

- Specific Interference Fit: Front tire standard specification dictates 110/70-17 54H (tubeless) for handling and stability Protocol.

Professional Workshop Service Manual & Technical Specifications

Systematic Reference Manual: Motorcycle Suzuki GSX250F Service & Repair: GSX250FWN, GSX250FP, GSX250FR - Factory Operations Guide Technical-Repository

Equipment-Series: GSX250F, GSX250FWN (1992), GSX250FP (1993), GSX250FR (1994) // Service-Level: Factory Operations / Maintenance and Tune-up Systems Logic // Equipment-Series: Four-stroke water-cooled engine and chassis documentation.

| Document Overview | Content Categories | Scope & Documentation |

|---|---|---|

| Periodic Maintenance & Engine Systems | 200 pages, comprehensive factory reference | Complete specifications and procedures included |

| General Information & Electrical Systems | Transmission, brakes, suspension coverage | All major systems documented with reference data |

| Cooling, Fuel, and Chassis Components | Troubleshooting and diagnostic procedures | Wire routing, cable guides, and service data provided |

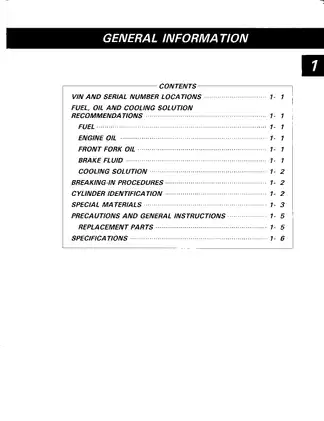

The manual presents information on general information and specifications covering VIN locations, fuel and oil recommendations, breaking-in procedures, and special materials required for maintenance work. Subsequent sections document periodic maintenance schedules, detailing inspection intervals for all major systems including battery status, air cleaner condition, exhaust pipe fastening, tappet clearance, spark plug service, engine oil and filter replacement, fuel lines, carburetor adjustment, cooling system integrity, clutch operation, drive chain slack, brake performance, steering assembly, front fork operation, rear suspension alignment, and chassis bolts and nuts torque specifications. The manual covers engine components removable with the engine in place, engine removal and remounting procedures, and comprehensive engine disassembly guidance. Inspection guidelines are provided for cylinder head distortion, valve stem runout, valve face wear, valve guide clearance, camshaft journal wear, cam chain length, cylinder bore condition, piston diameter measurement, piston ring groove clearance, piston pin bore sizing, and conrod bearing selection. Reference data is included for compression pressure specifications, oil pressure check procedures, signal generator resistance testing, ignition coil spark performance, and starter motor brush length limits. Alignment specifications are included for valve timing, cam sprocket positioning, and transmission gear ratios. Documentation sections include fuel and lubrication system coverage with fuel cock removal, fuel pump inspection, fuel tank service, carburetor specifications and balancing procedures, and complete lubrication system chart showing oil flow paths. This manual documents torque specifications for the clutch sleeve hub to ensure proper assembly security.

The document addresses cooling system description including thermostat operation, water pump bearing inspection, mechanical seal replacement, and coolant mixing ratios with temperature protection curves. Electrical system sections present ignition system signal generator checks, ignition coil spark performance testing, spark plug gap specifications, ignitor unit checking procedures using digital equipment, charging system regulator and rectifier function, AC generator no-load performance testing, starter system relay inspection, side-stand and ignition interlock relay operation, solenoid control unit checking, water temperature meter accuracy verification, combination meter lamp specifications, switch continuity testing, and battery initial charging procedures with electrolyte filling instructions. Chassis sections document fairing removal, front wheel bearing installation, tire removal and mounting with specialized equipment, front brake pad replacement, caliper and disc inspection, master cylinder reassembly procedures, front fork oil seal installation, and steering stem bearing races installation. Service procedures cover rear wheel reassembly with cushion lever bearing installation, rear brake caliper housing bolt tightening, rear swingarm suspension bearing installation, and suspension reassembly information with specific torque values. Troubleshooting sections organize complaints by system including engine noise diagnosis, clutch operation issues, transmission shifting problems, carburetor adjustment needs, electrical system failures, and chassis wear indicators. Wire routing diagrams show harness clamping points and lead wire positioning. Cable routing illustrations detail throttle cable paths, clutch cable positioning, and speedometer cable guides. Hose routing documentation includes coolant circulation paths, brake hose union positioning, and fuel hose clamping locations. Special tools sections list compression gauges, dial gauges, micrometer specifications, plastigauge sets, bearing installers, fork oil level gauges, and steering bearing removal equipment. Comprehensive tightening torque charts organize fasteners by diameter with conventional bolt and "T" marked bolt specifications in Newton-meters, kilogram-force-meters, and pound-force-feet units.

Service data tables document valve and guide specifications including intake and exhaust dimensions, tappet clearance cold state ranges, valve guide internal diameter standards, and valve stem outer diameter tolerances. Camshaft and cylinder head data include cam height service limits, camshaft journal oil clearance specifications, camshaft runout limits, and cam chain 20-pitch length reference values. Cylinder, piston, and piston ring data present compression pressure specifications, piston-to-cylinder clearance ranges, cylinder bore diameter limits, and piston ring end gap service limits. Thermostat and radiator data include valve opening temperature ranges and mechanical seal specifications. Transmission and drive chain data document primary reduction ratios, final reduction gear ratios for all five forward speeds, shift fork-to-groove clearance standards, and drive chain slack specifications. Carburetor specifications include bore size, idle speed targets, float height settings, and jet sizing with needle jet positioning. Electrical data cover ignition timing reference points, spark plug gap ranges, signal coil resistance values, ignition coil primary and secondary winding resistances, and battery capacity designations. Brake and wheel data include disc thickness limits, master cylinder bore diameters, wheel rim runout service limits, and tire tread depth requirements for front and rear applications. Suspension data document front fork stroke length, fork spring free length, fork oil level height, and rear wheel travel specifications.

Additional model-specific service data for GSX250FN ('92-model) variants document valve clearance specifications for intake and exhaust operations, noting differences in engine oil capacity without filter change versus with filter change during overhaul procedures. The appendix consolidates valve and guide dimensional data, camshaft and cylinder head tolerance specifications, and additional service data for comparative reference across model year variations.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)