2002-2004 Honda CBR954RR Fireblade Service Manual (495 P.)

954cc 4-cylinder inline engine with comprehensive service procedures for fuel injection, ignition, cooling, clutch, transmission, chassis, and suspension systems.

Manual Preview

Sample pages from the 2002-2004 Honda CBR954RR Fireblade Service Manual (495 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda CBR954RR Fireblade — 2002–2004 Comprehensive Factory Reference | CBR954RR Series Repository.

- Calibrated Displacement Data: 954 cm³ (58.2 cu in) is established at the engine cylinder volume Matrix.

- Rated Maximum Power Output: For optimal performance, 11.5:1 compression ratio yields the peak combustion efficiency Standards.

- Critical Fuel Capacity Specification: The fuel tank reaches 18.0 liter (4.76 US gal, 3.96 Imp gal) — specifies the reserve margin Protocol.

- Universal Engine Oil Capacity: At disassembly, 4.0 liter (4.2 US qt, 3.5 Imp qt) is standardized to maintain lubrication Architecture.

- Maximum Oil Pressure Rating: 490 kPa (5.0 kgf/cm², 71 psi) at 5,400 rpm/(80°C/176°F) corresponds to system protection Norms.

- Documented Valve Clearance Data: Intake valve gap maintains 0.16 ± 0.03 mm (0.006 ± 0.001 in) cold lash setting Guidelines.

Professional Workshop Service Manual & Technical Specifications

Technical Installation Manual: Honda CBR954RR Fireblade Manual - Comprehensive Factory Repair Guide (2002-2004) Field-Reference

Service-Level: 2002-2004 Honda CBR954RR Fireblade // Service-Level: Motorcycle Service / Engine, Transmission, and Suspension Logic // Application-Range: Factory Service Procedures, Complete Technical Documentation, Component-Level Reference Data.

| Integrated-Framework | Parameters | Calibration-Spec |

|---|---|---|

| Engine Systems | Displacement: 954 cm³, DOHC 4-Cylinder Configuration | Valve clearance and timing specifications included |

| Fuel Injection | PGM-FI System with Digital Control | Fuel pressure and injector resistance documented |

| Suspension & Chassis | Inverted fork, Swingarm rear suspension | Pre-load and damping adjustment reference data |

| Transmission | 6-Speed Constant Mesh | Gear ratio specifications provided |

| Brake System | Hydraulic Double Disc (Front), Single Disc (Rear) | Pad thickness and fluid specifications documented |

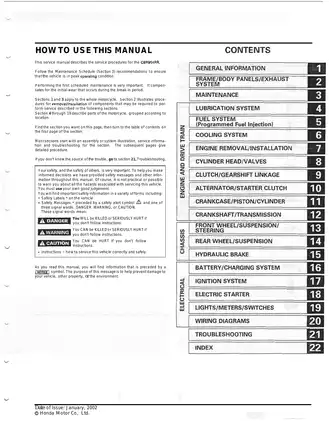

Providing a structural breakdown of the manual's contents, this reference documents the intake, fuel delivery, ignition, cooling, and drivetrain mechanisms. The manual covers engine and transmission systems, explores electrical and lighting circuits, and addresses suspension component service procedures. The document structures frame/body panel removal alongside exhaust system maintenance, incorporates cooling system procedures including thermostat and water pump reference data, and provides detailed crankcase and piston assembly guidance.

Fundamentally requiring knowledge of metric fastener specifications, the manual documents torque values for critical engine fasteners to ensure proper assembly. Technical notes are provided for bearing clearances, oil circulation passages, and component alignment procedures. Adjustment procedures are detailed for valve clearance using feeler gauges and shim selection tables. Quality checks are addressed for piston ring end gaps, cylinder bore measurements, and crankshaft runout verification.

The engine control module (ECM) section includes comprehensive self-diagnostic procedures with malfunction indicator lamp (MIL) failure codes 0 through 35, enabling systematic troubleshooting of the PGM-FI system. Timing hole alignment procedures, peak voltage inspection methods for ignition and cam pulse generators, and fuel pressure measurement techniques are documented. The document includes wiring diagrams detailing cable and harness routing for all engine management sensors and actuators.

Service sections detail mechanical fuel pump operation, fuel filter replacement sequences, pressure regulator function, and fuel line inspection protocols. Clutch assembly disassembly procedures, shift drum and shift fork service instructions, and gearshift linkage adjustment methods enable drivetrain maintenance. Cooling system procedures include radiator removal, water pump mechanical seal inspection, and coolant concentration verification using hydrometer testing.

Documentation addresses steering head bearing adjustment, fork assembly disassembly including oil level measurement at 73 mm specification, and damper rod adjuster case procedures. Front brake caliper piston removal, master cylinder seal replacement, and rear master cylinder push rod assembly are thoroughly illustrated. The manual documents suspension linkage bearing replacement, shock absorber nitrogen pressure release procedures, and swingarm pivot bearing service using specialized pressing tools.

Electrical system sections cover alternator stator removal, flywheel holder tool usage, and starter one-way clutch assembly procedures. Battery testing, spark plug gap specifications (0.80–0.90 mm standard), and ignition coil mounting are documented. The document includes emission control system diagrams showing PAIR (Pulse Secondary Air Injection) solenoid valve operation, evaporative emission (EVAP) canister purge control for California models, and heated oxygen sensor function.

Maintenance schedule tables reference service intervals in odometer readings (16,000 km / 25,600 km intervals) alongside monthly inspection requirements. The manual documents that torque specifications for the crankshaft main journal 9 mm bolts utilize the Plastic Region Tightening Method, requiring new bolts with specific oil additive coatings that must not be removed.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)