2006 Ski-Doo REV Series Service Manual: GSX/GTX/MX Z/Summit (502 P.)

377/552/593 engines with RAVE valve, DPM, and Power Tek ignition systems. Covers fan-cooled and liquid-cooled models including Expedition, Adrenaline variants. PN MMR2005-059.

Manual Preview

Sample pages from the 2006 Ski-Doo REV Series Service Manual: GSX/GTX/MX Z/Summit (502 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Bombardier MX Z 600 HO (CG5A, CG5B) — 2006 Operational Directory Digest | MX Z 600 HO Series Packet.

- Authorized Interference Fit: Piston/cylinder wall clearance is calibrated to 0.104–0.136 mm (0.004–0.005 in) for precise engine architecture Mapping.

- Published Circuit Specs: For optimal performance, Engine fuel capacity reaches 30 L (7.9 US gal) governing operational Configuration.

- Reference Climate Parameters: Coolant system capacity is specified as 3.5 L (0.92 US gal) across all liquid-cooled applications Benchmarks.

- Fundamental Physical Specs: The compression ratio supports 9.5:1 for standard combustion chamber pressure Logic.

- Specific Coupling Torques: Cylinder head bolts are rated at 29 N•m (21 lbf•ft) in criss-cross sequence Range.

- Core End Play: Crankshaft end-play is calibrated to 0.10–0.30 mm (0.004–0.012 in) within acceptable bearing tolerance Baseline.

Professional Workshop Service Manual & Technical Specifications

Consolidated Safety Assembly Manual: Snowmobile Ski-Doo REV Series Service Manual (2006): GSX, GTX, MX Z, Summit, Expedition, and Fan / Liquid Cooled Models Snowmobile 2006 Specification-Set

Service-Level: Bombardier GSX, GTX, MX Z, Summit, Expedition (2006 models) // Operational-Scope: Fuel system, ignition timing, and engine management protocols // Operational-Scope: Complete technical specifications for two-stroke and liquid-cooled powerplants.

| Service-Nexus | Rating | Calibration-Spec |

|---|---|---|

| Engine Assembly Procedures | Complete | Piston/cylinder clearance, ring gaps documented |

| Fuel and Carburetor Systems | Comprehensive | Jet sizing, float height, and adjustment reference data |

| Transmission and Drive Components | Full Coverage | Belt alignment, pulley positioning specifications |

| Cooling and Thermal Management | Detailed | Coolant capacity, thermostat specifications included |

| Electrical and Ignition Systems | Complete | Spark plug specifications, ignition timing charts |

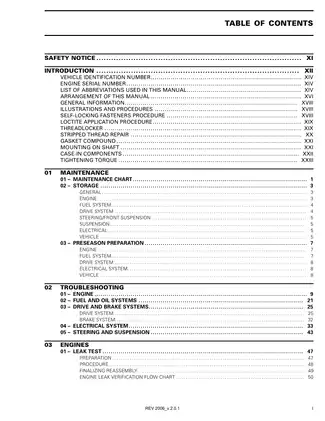

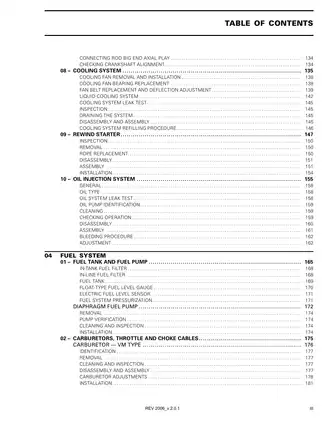

Repair data is categorized into systematic sections that address engine architecture, including fuel delivery components, ignition timing calibration, and transmission system operation. The manual structures maintenance procedures for carburetors and choke mechanisms, synchronization of throttle assemblies, and drive pulley calibration according to manufacturer specifications. Technical notes are provided for cylinder head warpage measurement, piston ring end gap inspection, and crankshaft deflection verification within documented tolerances. Quality checks are addressed for cooling system integrity, including leak test procedures and coolant refilling sequences. The RAVE valve system documentation covers bellows integrity assessment, compression spring tension verification, and solenoid function testing.

Adjustment procedures are detailed for engine idle speed, carburetor air/fuel mixture ratios, and throttle cable tension to maintain optimal performance. Timing procedures are documented for magneto system setup, ignition coil function, and trigger coil positioning to ensure proper spark advance. The manual includes comprehensive wiring diagrams for all electrical circuits, connector pinout specifications, and circuit protection through fuse and relay documentation. The document provides torque specifications for crankshaft bearing assembly, including proper installation sequences and heating procedures to prevent assembly damage. Technical guidance covers fuel system pressurization testing, oil injection pump calibration, and DPM (Digital Performance Management) system operation across carburetor and electronic fuel injection variants.

The manual documents torque specifications for engine mounting fasteners and suspension components to ensure proper axial load stability.

FAQ

Customer Reviews

Read what our customers say about this Ski-Doo Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)