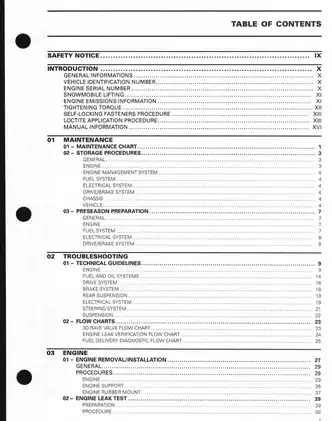

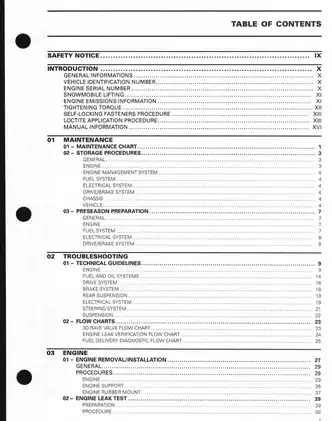

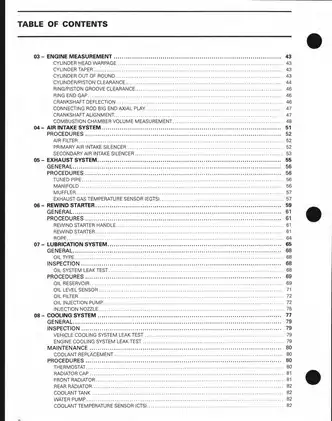

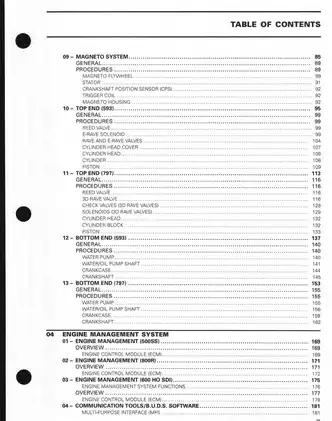

2008 BRP Ski-Doo REV-XP Shop Manual — Technical Service Guide

Complete technical reference for REV-XP 500SS/600 HO SDI/800R Power TEK engines. Covers service procedures, diagnostics, and repair specifications. PN 2BPSBX5A9Y1000001

Manual Preview

Sample pages from the 2008 BRP Ski-Doo REV-XP Shop Manual — Technical Service Guide manual

Purchase & Download

Models Covered & Key Technical Specifications

BRP 2008 Ski-Doo REV-XP Series (2BPSBX5A9Y1000001) — 2008 Precision Engineering Vault | REV-XP Series Repository.

- Nominal Displacement Data: 593 cc (500SS) and 797 cc (800R) engine cylinder volumes represents the primary architecture Framework.

- Prescribed Power Output: For optimal performance, 8600 RPM is standardized as the engine speed limiter maximum rated threshold Specifications.

- System Pressure Specification: 90 kPa (13 PSI) is standardized to the radiator cap pressure rating Baseline.

- Technical Coolant Specs: The cylinder head thermostat is set to open at 37°C (99°F) for standard coolant circulation Logic.

- Standard Fuel Injection: 400 kPa (58 PSI) pressure yields the fuel pump delivery specification on 600 HO SDI models Benchmarks.

- Defined Freezing Point: Coolant mixture reaches -37°C (-35°F) is established at the minimum freeze protection Range.

Professional Workshop Service Manual & Technical Specifications

Detailed Installation Overhaul Manual: BRP Ski-Doo REV-XP Shop Manual – Snowmobile (654 Pages) | Shop Standards Field-Reference

Unit-Designations: 2008 BRP Ski-Doo REV-XP Series (GSX Limited, GSX Sport, MX Z Adrenaline, MX Z Renegade, MX Z TNT, MX Z Trail, MX Z X, Summit Everest, Summit X) // Specification-Class: Rotax 593cc and 797cc Twin-Cylinder Engine Classification / Liquid-cooled 2-Stroke Architectures // Year-Coverage: 2008 Model Year Complete Service Reference.

| Service-Nexus | Technical-Path | Context |

|---|---|---|

| Engine Disassembly Procedures | Top End Components (Cylinder Head, Piston, RAVE Valves) | Complete removal and inspection protocols documented |

| Drive System Operations | Belt, Pulley, and Chaincase Assemblies | Service and adjustment sequences provided |

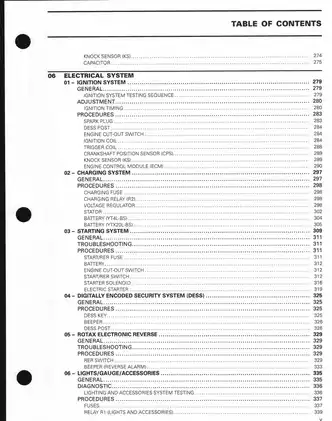

| Magneto and Ignition Architecture | Crankshaft Position Sensors, Trigger Coils, Stator Systems | Full testing and replacement procedures included |

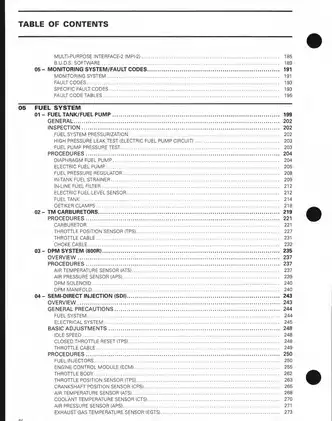

Integrated service sections encompass engine removal and installation, covering the 593cc 500SS/600 HO SDI platforms alongside the 797cc 800R Power TEK configurations. Lubrication system pathways, fuel delivery networks via Mikuni TM-40 carburetors and Semi-Direct Injection architectures, and electrical management through Denso 360W/480W magneto systems are systematically documented. The manual references RAVE valve operations (pressure-operated designs on 500SS engines, Electronic E-RAVE on 600 HO SDI units, and 3D vacuum-modulated configurations on 800R Power TEK variants) with comprehensive assembly and diagnostic procedures. Coolant system architecture incorporates ethylene glycol specifications, thermostat opening parameters, and radiator maintenance protocols throughout multiple sections. Brake system coverage includes hydraulic fluid types, pad replacement pathways, and caliper service details. The document includes wiring diagrams, electrical connector specifications for Sumitomo, Deutsch, Packard, AMP, Kostal, and battery terminal configurations.

Core Protocol

Reassembly procedures are specified for engine bottom-end components including water pump assemblies, bearing installation sequences, and crankcase assembly with Loctite 5910 sealing compound application methodologies. Oil injection pump alignment procedures document cable adjustment specifications with detailed torque requirements across model variants. The manual details removal and installation protocols for front and rear radiators, including rivet drilling procedures and coolant tank service steps. Storage procedures encompass fuel stabilizer application, engine lubrication oil injection protocols, and vehicle protection measures during extended idle periods. Preseason preparation sections reference spark plug replacement timing, throttle cable adjustment, and brake system inspection before operational use.

Diagnostic Parameters

Service intervals are documented for drive belt condition assessment, track tension verification, and chassis suspension component inspection at specified maintenance intervals. Technical guidelines provide troubleshooting logic organized by symptom categories including engine starting failures, irregular idle conditions, high operating temperatures, acceleration performance deficiencies, and electrical system malfunction identification. The document includes 3D RAVE valve flow charts, engine leak verification protocols, and fuel delivery diagnostic decision trees with pressure testing specifications. Engine measurement sections detail cylinder taper assessment procedures, piston-to-cylinder clearance calculations, ring end gap verification methodologies, and crankshaft deflection measurement techniques on bench-mounted configurations.

Modular Benchmarks

Component locations are identified for all major assemblies including the Engine Control Module (ECM) positioning, fuel pump placement, and oil injection pump mounting arrangements. Electrical connector types and pin configurations are cataloged with corresponding wire color designations and continuity testing parameters. The manual documents torque specifications organized by fastener grade (5.8, 8.8, 10.9, and 12.9 property classes) with metric conversions to foot-pound and inch-pound measurement units. DPM (Digital Performance Management) system operation, E-RAVE solenoid functionality, and knock sensor diagnostic procedures are detailed with B.U.D.S. software activation protocols.

Core Interface

Service procedures are documented for cylinder head removal, featuring valve cover extraction, spark plug removal sequences, and coolant socket disconnection steps. RAVE valve disassembly protocols include bellows removal, piston extraction, and spring tension adjustment methodologies. The document specifies reed valve installation orientation, blade stopper distance verification, and intake adapter sealing procedures. Exhaust system service encompasses tuned pipe spring removal using specialized tools (exhaust spring installer/remover P/N 529 035 401), manifold screw torque specifications segregated by engine platform, and muffler attachment spring installation protocols.

Technical Sequences

Calibration requirements are specified for oil pump cable adjustment using throttle free play wedge tools (P/N 529 036 042), with cable adjuster positioning on both 500SS (16.5 mm specification) and 600 HO SDI (20.0 mm specification) engines. Drive belt height adjustment protocols reference deflection measurement criteria and pulley distance establishment procedures. Track tension and alignment procedures document the interrelated nature of these adjustments and provide specification ranges for slack measurement and lateral positioning. The manual documents the professional pathway for cooling system leak testing using vacuum/pressure pump equipment (P/N 529 021 800) with pressure maintenance criteria (100 kPa / 15 PSI for system verification, 34 kPa / 5 PSI for engine internal sealing validation).

The manual documents torque specifications for engine suspension bolts to ensure proper cyclic stress resistance. Ignition timing reference data, fuel injection pressure parameters, and coolant temperature sensor resistance values across operating temperature ranges are included in comprehensive specification tables. The document provides troubleshooting guidance for drive system symptoms including acceleration deficiency diagnosis, maximum RPM achievement verification, and belt wear pattern interpretation relative to pulley condition assessment. Communication tool protocols for B.U.D.S. software connectivity establish diagnostic procedures for fault code retrieval and component activation testing procedures on the Engine Management System architecture.

FAQ

Customer Reviews

Read what our customers say about this Ski-Doo Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)