Ski-Doo repair manual (2009-10): GTX, GSX, GTX, MKZ, Summit

Manual Preview

Sample pages from the Ski-Doo repair manual (2009-10): GTX, GSX, GTX, MKZ, Summit manual

Purchase & Download

Models Covered & Key Technical Specifications

- GTX LE 600 HO E-TEC

- GSX Limited 600 HO E-TEC

- GSX Sport 500SS

- GTX Sport 500SS

- MKZ 50TH 600 HO E-TEC

- MXZ Adrenaline 600 HO E-TEC

- MXZ Adrenaline 800R Power TEK

- MXZ Renegade X 600 HO E-TEC

- MXZ Renegade X 800R Power TEK

- MXZ Trail 500SS

- MXZ TNT 500SS

- MXX TNT 600 HO E-TEC

- MXZ X 600 HO E-TEC

- MXZ X 800R Power TEK

- Summit 50TH 800R Power TEK

- Summit Everest 600

- Summit Everest 600 HO E-TEC

- Summit Everest (146) (154) (163) 800R Power TEK

- Summit Hill Climb (154) 800R Power TEK

- Summit X 600 HO E-TEC

- Summit X (146) (154) (163) 800R Power TEK

- REV XR 1200 4-TEC

- GTX LE

- GTX SE

- GSX Limited

- MXZ Renegade

- MXZ Renegade X

- MXZ TNT

- MXZ X

Production year(s): 2009-2010

Professional Workshop Service Manual & Technical Specifications

Targeted Technical Reference – 2009-2010 Ski-Doo Snowmobile Manual

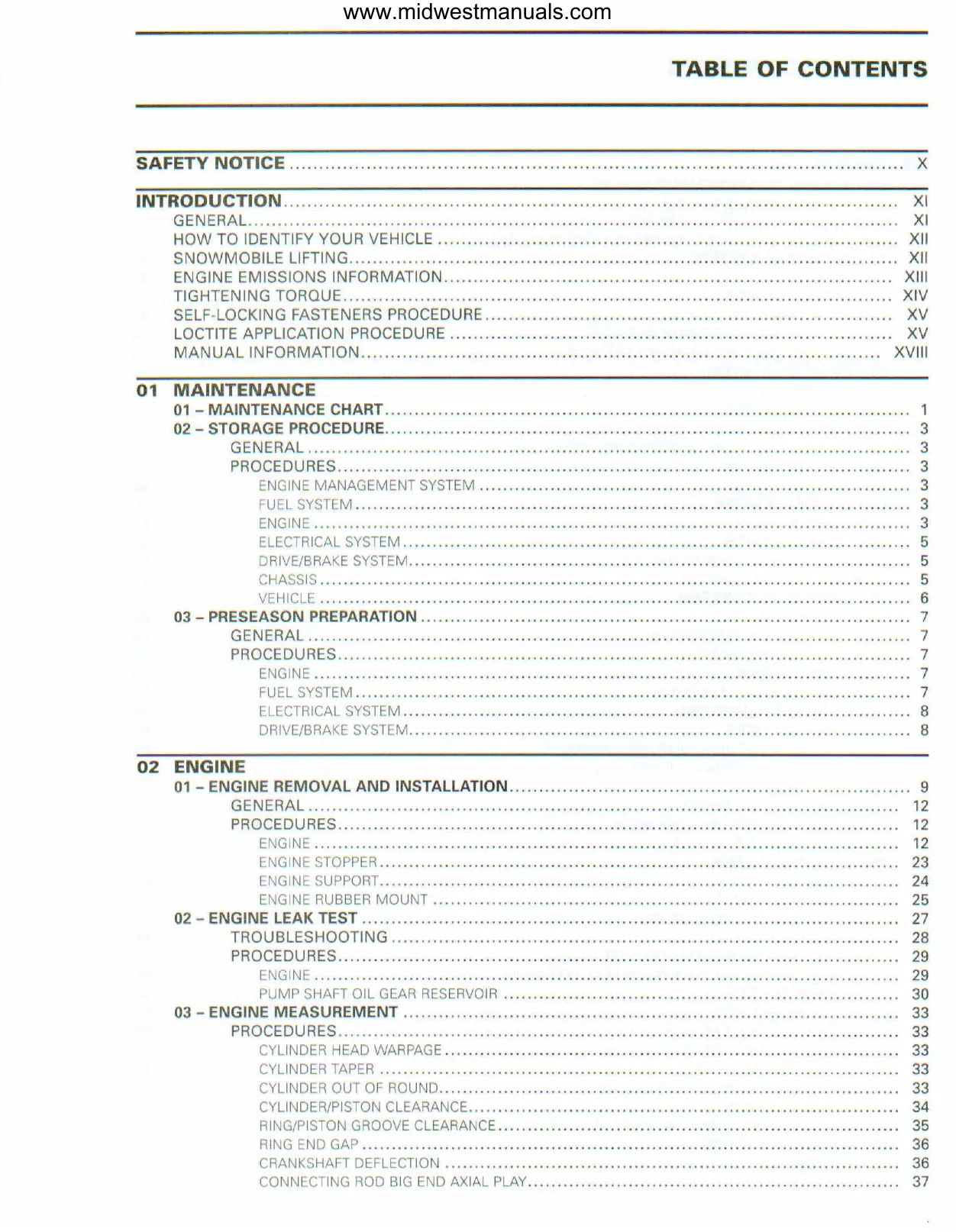

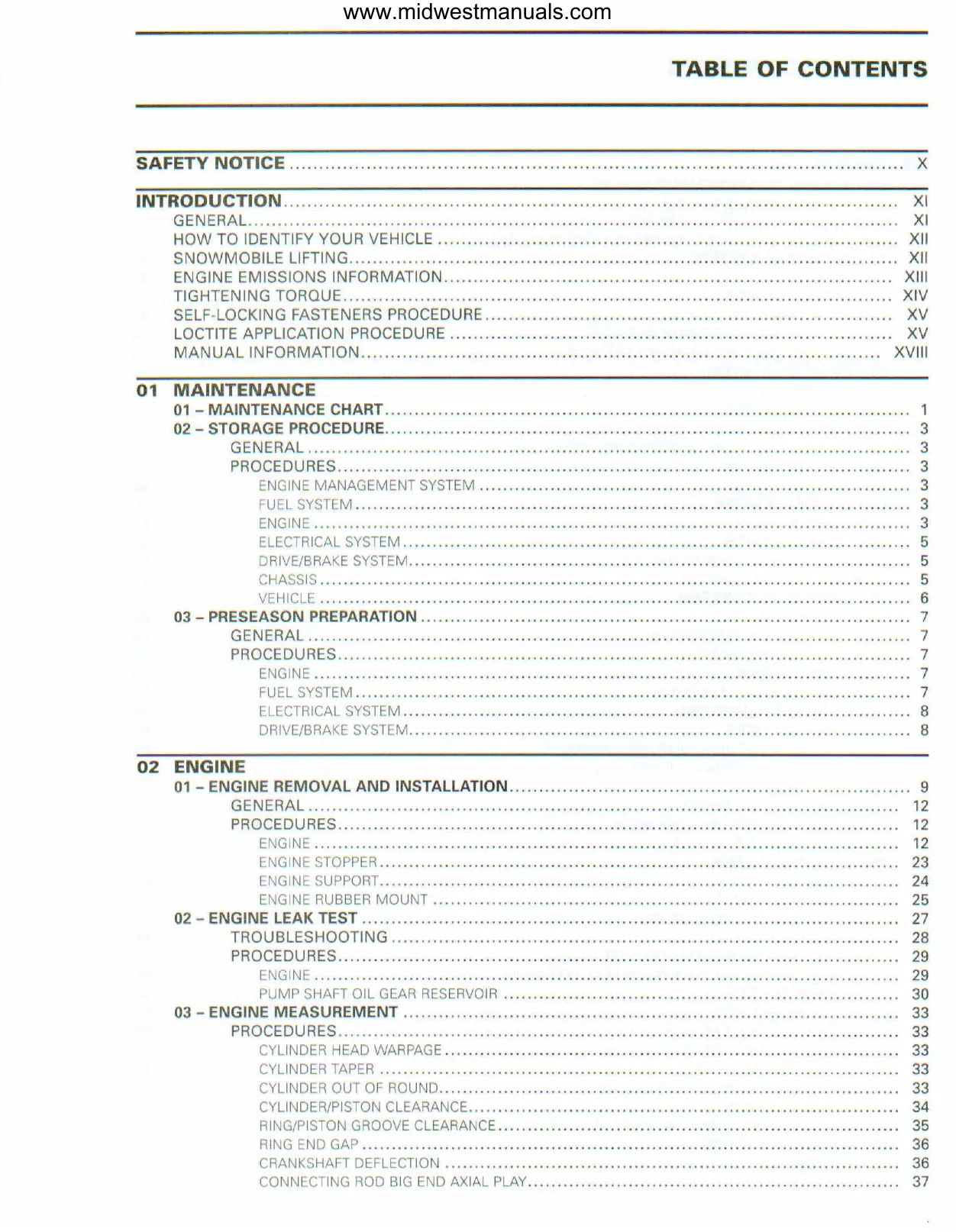

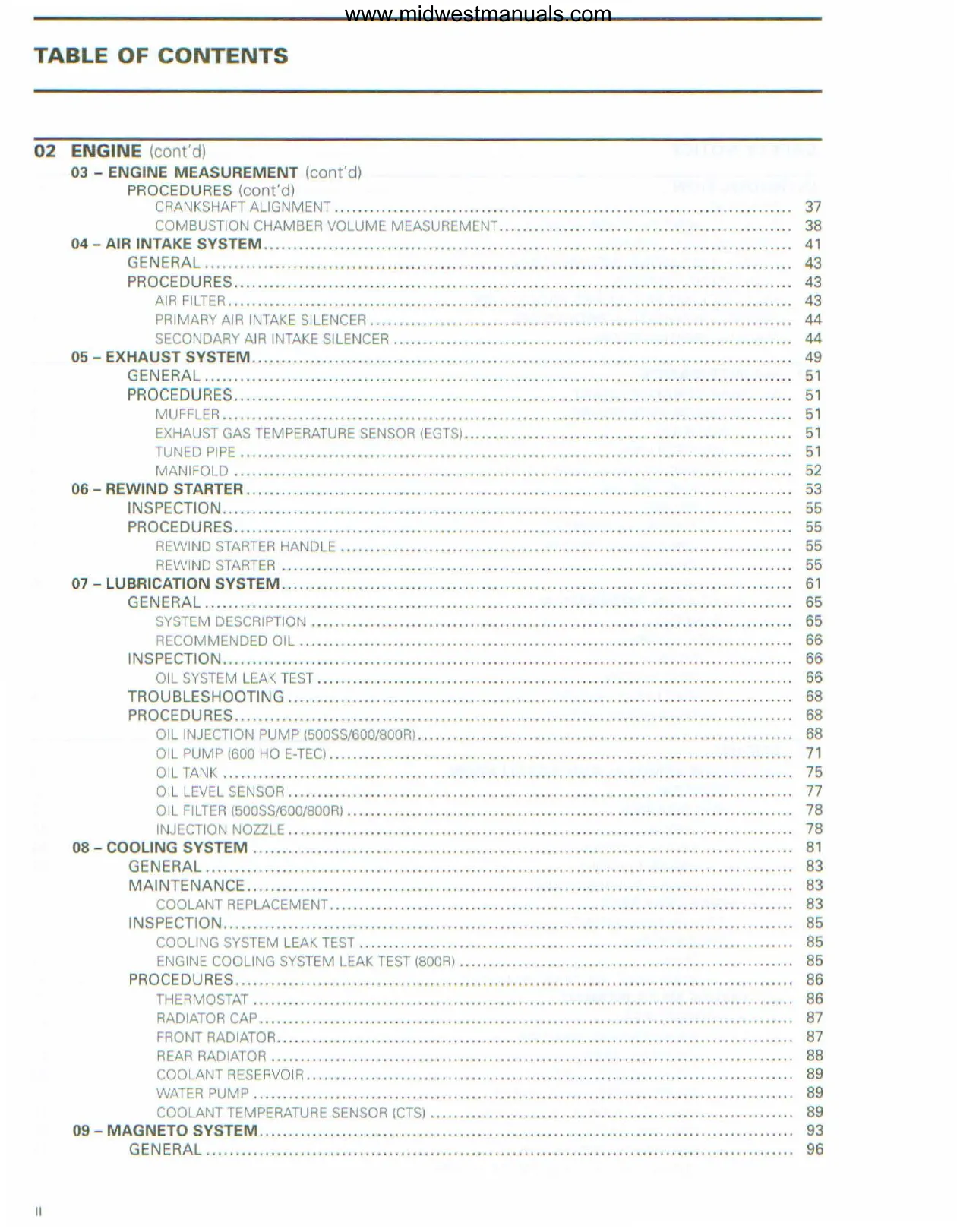

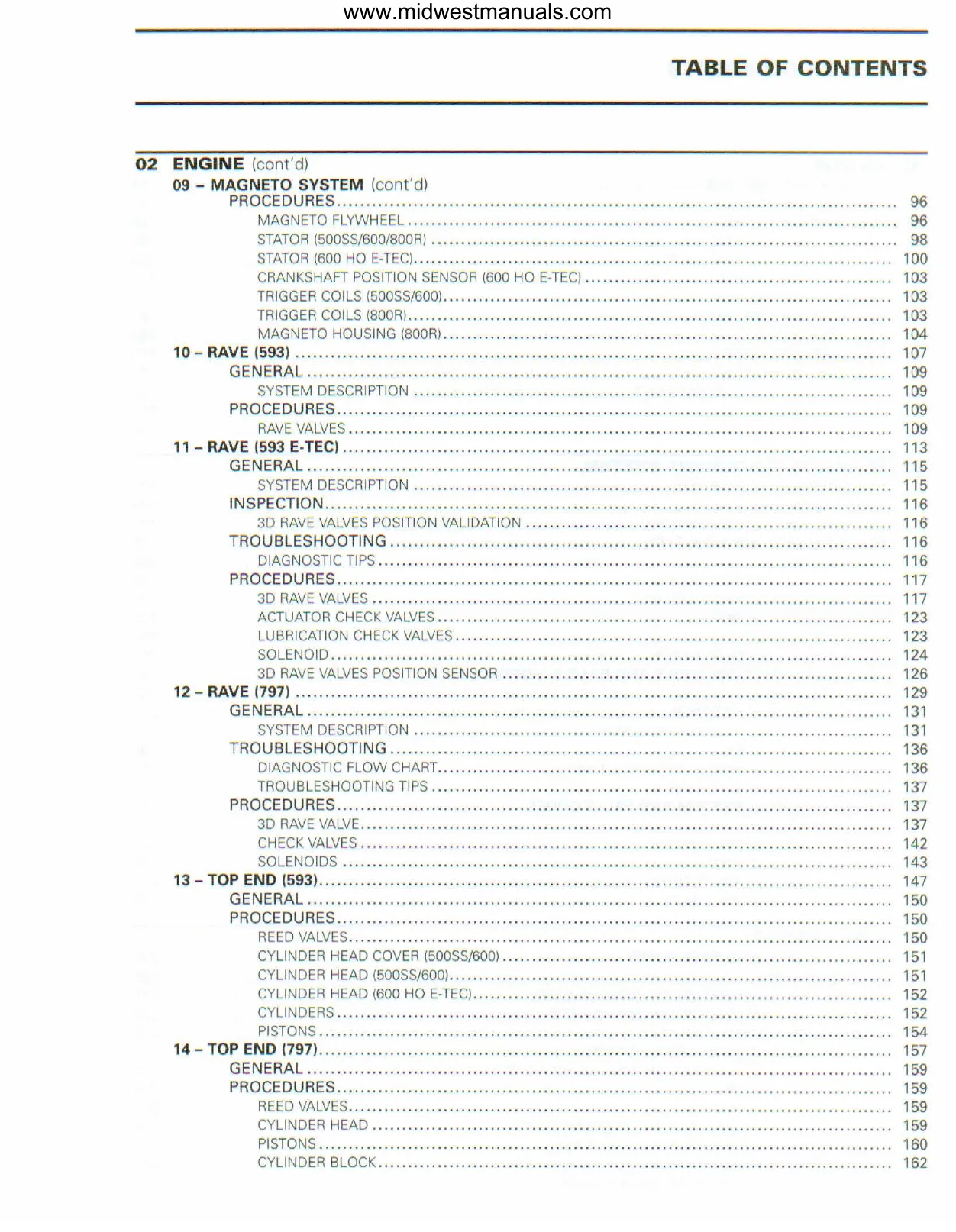

This service and repair manual provides structured technical reference coverage for a wide range of 2009 and 2010 Ski-Doo snowmobile models. It is designed to help users locate the exact technical information they need across mechanical, electrical and chassis domains without procedural repair narratives, enabling efficient verification of system coverage and component detail.

Covered Model Variants

| The manual includes documentation for multiple Ski-Doo series from 2009–2010, such as: | Model Variant | Covered |

|---|---|---|

| GTX LE 600 HO E-TEC | Yes | |

| GSX Limited 600 HO E-TEC | Yes | |

| GSX Sport 500SS | Yes | |

| GTX Sport 500SS | Yes | |

| MKZ 50TH 600 HO E-TEC | Yes | |

| MXZ Adrenaline 600/800R Power TEK | Yes | |

| MXZ Renegade X | Yes | |

| Summit 50TH/EVEREST 600/800R | Yes |

Manual Focus and Structure

The documentation organizes major domains in a way that enables fast reference and comparison:

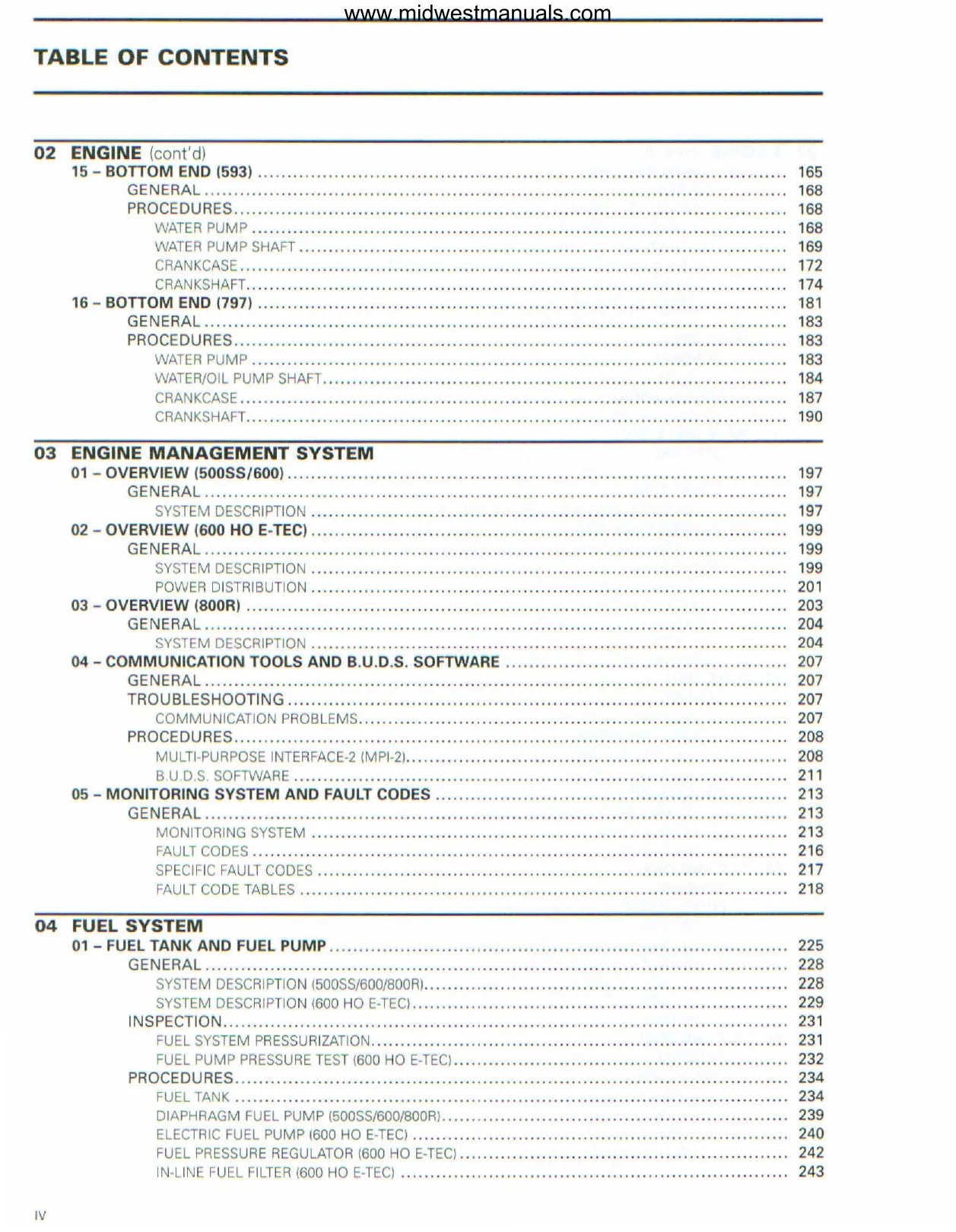

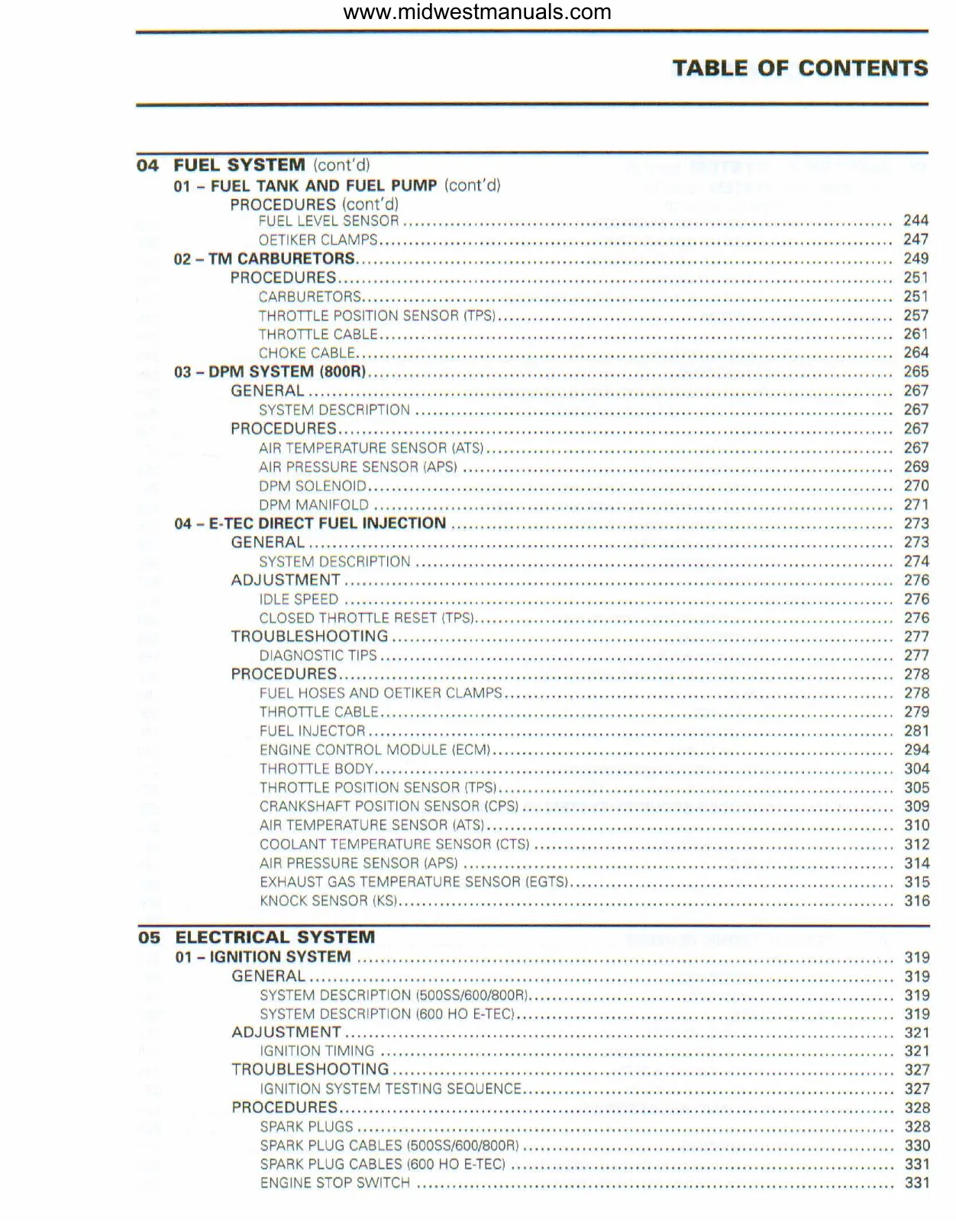

- Engine and Performance Systems: Technical specifications and structural breakdowns for powertrain elements, including two-stroke E-TEC engine systems and performance characteristics.

- Fuel and Lubrication Systems: Domain groupings that reflect fuel path mapping, injection system components, lubrication architecture and pressure parameters across variants.

- Chassis, Suspension & Brake Systems: Structural summaries of suspension linkages, brake domains and control assemblies as they relate to overall handling and dynamics.

- Electrical and Control Architecture: Wiring harness layouts, ignition circuits, charging systems and module groupings with domain-level organization without step-by-step narrative.

- Cooling and Intake Domains: Reference breakdowns for cooling circuits, intake paths and sensor groupings that support performance parameters.

Typical Reference Sections Included

- Multi-model specifications and identification data

- Grouped electrical schematics with circuit family segmentation

- Engine and fuel delivery system maps by model type

- Suspension, brake and chassis structural breakdowns

FAQ

Customer Reviews

Read what our customers say about this Ski-Doo Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)