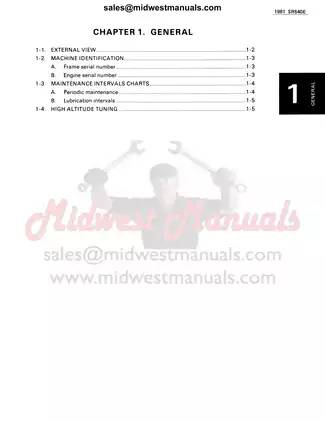

1981-1991 Yamaha SRV540 Series / SR540E / SR-V Service Manual

Technician-level documentation for SRV540 series engines covering fuel systems, ignition, carburetor adjustment, and engine overhaul procedures. Complete service specs included.

Manual Preview

Sample pages from the 1981-1991 Yamaha SRV540 Series / SR540E / SR-V Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha SRV540 Series SR540E SR-V — 1981–1991 Integrated Database Bundle | SRV540 Series Repository.

- Maximum Clamp Forces: 25 N·m is measured at the fastening topology Standards.

- Universal Tank Capacity: For operational efficiency, 28 L is set to the fuel system bounds Topology.

- Fundamental Adjustment Range: Spark plug gap limits at 0.6–0.7 mm (0.024–0.028 in) Matrix.

- Specific Generation Capacity: The cooling system requires 3.0 L (0.79 gal) Standards.

- Critical Velocity Specs: Maximum engine speed is established at 7500 rpm Protocol.

- Rated Tightening Data: Cylinder head bolts controls 40 N·m (29 lb-ft) Margin.

Professional Workshop Service Manual & Technical Specifications

In-Depth Overhaul Electrical Manual: Yamaha SRV540 Series SR540E SR-V 1981-1991 Snowmobile Service Procedure-Database

Technical-Benchmarks: Yamaha SRV540 Series, SR540E, SR-V models (1981-1991) // Equipment-Series: Snowmobile maintenance and engine diagnostics // Subsystem-Focus: Electrical systems, fuel delivery, and mechanical component documentation.

| Metric | Value | Validation-Data |

|---|---|---|

| Document Type | Service Manual | Complete specifications provided |

| Model Coverage | SRV540 Series variants | 1981-1991 production years |

| Primary Systems | Engine, transmission, electrical | Documented across chapters |

Following OEM groupings, the manual includes documentation on engine operation and mechanical function, fuel system components and carburetor adjustment procedures, electrical circuit diagrams and starter motor systems, transmission assembly and drive belt information, and suspension framework with track configuration details, organized to address comprehensive maintenance and diagnostic requirements.

Comprehensive Benchmarks

Timing procedures are documented for engine synchronization and ignition system parameters. The manual provides extensive coverage of two-stroke engine configurations, including cylinder head and piston assembly references, crankshaft specifications, and bearing clearance data. Service intervals and component replacement guidance are presented throughout, with detailed attention to fuel mixture ratios and lubrication requirements specific to the SRV540 platform.

Technical Framework

Technical notes are provided for electrical troubleshooting and wiring harness identification. The snowmobile's starting system, charging circuit, and lighting components receive dedicated coverage with schematic representations of electrical pathways. Documentation addresses ignition timing verification and magneto function testing, ensuring proper operation of the electronic control systems.

Advanced Protocol

Quality checks are addressed for carburetor performance and fuel delivery consistency. The document includes practical reference data on idle adjustment procedures, throttle cable routing, and fuel filter maintenance schedules. Intake manifold gasket specifications and float bowl configuration details support comprehensive carburetor service and restoration activities.

Diagnostic Topology

The transmission section documents gear engagement points and clutch assembly functions within the drive system. Belt tension guidelines and pulley alignment information provide specifications for the continuously variable transmission components. Secondary clutch operation and centrifugal engagement mechanics receive systematic documentation.

Diagnostic Architecture

The troubleshooting chapter addresses common operational concerns and diagnostic methodologies for identifying system failures. Documentation extends to track suspension geometry, ski alignment procedures, and chassis structural references. The manual documents torque specifications for fastener applications to ensure proper clamp load consistency across critical assemblies.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)