1994-1997 Nissan D21 Truck Automatic Transmission Service Manual

Technical reference for the 1994-1997 Nissan D21 truck with detailed service procedures for the automatic transmission. PN 0131-nissan-d21-truck-1994-1996-1997.zip

Manual Preview

Sample pages from the 1994-1997 Nissan D21 Truck Automatic Transmission Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Detailed Configuration Field Manual: Truck Manual for Nissan D21, 1994-1997 repair guide Specification-Guide Unit-Designations: 1994-1997 Nissan D21 // Machine-Range: Truck / Automatic Transmission Logic // Unit-Designations: Detailed technical specifications.

| Metric | Operational-Logic | Architecture |

|---|---|---|

| D21 Automatic Transmission | Service Manual | Repair Guide |

| Years Covered | 1994-1997 | N/A |

| Part Number | 0131-nissan-d21-truck-1994-1996-1997.zip | N/A |

| Language | English | N/A |

| File Size | 91.7892 MB | N/A |

| VIN Range | 1N6SD11S0RC300001 to 1N6SD11S0RC399999 | N/A |

Major sections focus on: Preparations and Precautions, Overall System, Troubleshooting, On-Vehicle Service, and Repair for Component Parts.

Reassembly procedures are specified for all major components, including detailed steps for the torque converter, control valve, and internal transmission parts. Service intervals are documented for regular maintenance checks and fluid changes. Component locations are identified for easy access and replacement. Service procedures are documented for component overhauls and system-level diagnostics. Calibration requirements are specified for ensuring optimal performance after repairs.

This manual includes diagnostic procedures, wiring diagrams, and detailed specifications to aid in troubleshooting and repair. It is designed to assist technicians in efficiently diagnosing and resolving issues related to the automatic transmission system.

Design System Fill: Functional Archive for proper system functioning. Advanced Deviation Limits: Original Dossier dictates the acceptable operational tolerances. Technical Load Capacity: Integrated Library is established at specified operational parameters. Standard Cycle Rate: Functional Archive for ensuring timely component cycling. Prescribed Package Size: Original Dossier yields the required component dimensions. Engineered Containment Volume: Integrated Library reaches its maximum operational capacity.

Professional Workshop Service Manual & Technical Specifications

Detailed Configuration Field Manual: Truck Manual for Nissan D21, 1994-1997 repair guide Specification-Guide

Unit-Designations: 1994-1997 Nissan D21 // Machine-Range: Truck / Automatic Transmission Logic // Unit-Designations: Detailed technical specifications.

| TOP | Metric | Operational-Logic | Architecture |

|---|---|---|---|

| D21 Automatic Transmission | Service Manual | Repair Guide | |

| Years Covered | 1994-1997 | N/A | |

| Part Number | 0131-nissan-d21-truck-1994-1996-1997.zip | N/A | |

| Language | English | N/A | |

| File Size | 91.7892 MB | N/A | |

| VIN Range | 1N6SD11S0RC300001 to 1N6SD11S0RC399999 | N/A |

Content Overview:

This manual covers the automatic transmission system for the 1994-1997 Nissan D21 truck. It provides comprehensive information on system operation, diagnosis, repair, and specifications.

Key Sections Include:

- Troubleshooting: Symptom charts, diagnostic flowcharts, and specific diagnostic trouble code (DTC) procedures.

- On-Vehicle Service: Procedures for inspections, fluid checks, and component adjustments without removing the transmission.

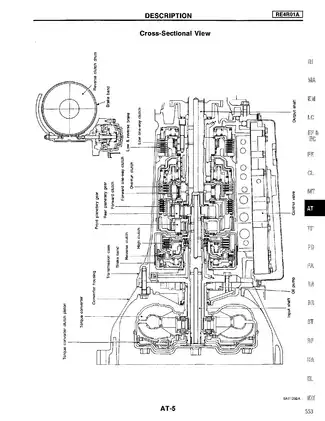

- Repair for Component Parts: Detailed disassembly, inspection, and assembly instructions for individual transmission components like the torque converter, control valve, clutch packs, and oil pump.

- Data and Specifications: Essential technical data, fluid capacities, pressure specs, and wear limits.

Repair Procedures and Diagnostics:

Reassembly procedures are specified for all major components, including detailed steps for the torque converter, control valve, and internal transmission parts. Service intervals are documented for regular maintenance checks and fluid changes. Component locations are identified for easy access and replacement. Service procedures are documented for component overhauls and system-level diagnostics. Calibration requirements are specified for ensuring optimal performance after repairs.

This manual includes diagnostic procedures, wiring diagrams, and detailed specifications to aid in troubleshooting and repair. It is designed to assist technicians in efficiently diagnosing and resolving issues related to the automatic transmission system.

Torque Statement: This manual documents torque specifications for various transmission components to ensure proper assembly stress control.

FAQ

Customer Reviews

Read what our customers say about this Nissan Truck manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)