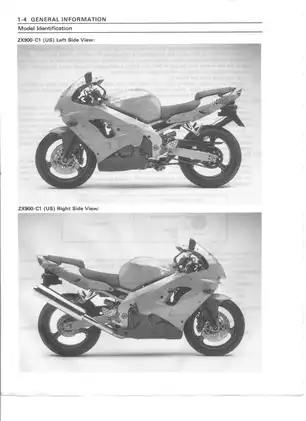

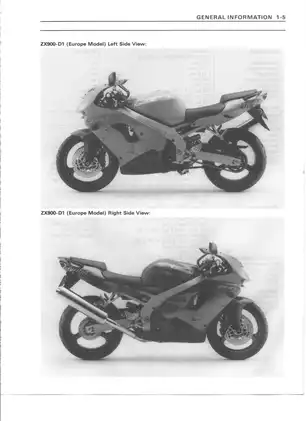

1998-2001 Kawasaki Ninja ZX-9R / ZX900-C1 Service Manual

Documents 1998-2001 Kawasaki Ninja ZX-9R / ZX900-C1 service procedures for the engine, fuel system, cooling system, and more. PN 99969-1099

Manual Preview

Sample pages from the 1998-2001 Kawasaki Ninja ZX-9R / ZX900-C1 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kawasaki Ninja ZX-9R (99969-1099) Manual: 1998-2001 Kawasaki Ninja ZX-9R / ZX900-C1 Service Manual Reference-Archive Kawasaki Ninja ZX-9R (99969-1099) Manual | Kawasaki Edition. Toolkit.

- General Cooling Specs: 2.9 L (0.77 US gal) signifies the system's coolant capacity Norms.

- Defined Physical Specs: The formatter board requires 64 MB for standard operation Logic.

- Nominal Physical Specs: 101 N·m (73 ft-lb) @ 9,000 rpm is standardized to the maximum torque output Bounds.

- Prescribed RPM Specs: The compression ratio reaches 11.5:1 dictates the combustion chamber pressure Matrix.

- General Thermal Envelope: For optimal operation, 15-30C defines the environmental limit Standards.

- Engine Displacement Data: 899 mL (54.9 cu in) establishes the engine displacement Architecture.

Professional Workshop Service Manual & Technical Specifications

Kawasaki Ninja ZX-9R (99969-1099) Manual: 1998-2001 Kawasaki Ninja ZX-9R / ZX900-C1 Service Manual Reference-Archive

Performance-Values: Kawasaki ZX900-C1 Ninja ZX-9R (1998-2001) // Repair-Classification: Motorbike / ZX900-C1 Series Logic // Performance-Values: Procedural Technical Compendium.

| Assessment-Parameter | Rating | Calibration-Spec |

|---|---|---|

| Engine Displacement | 899 mL | 54.9 cu in |

| Maximum Horsepower | 105 kW | 143 PS @ 11,000 r/min |

| Maximum Torque | 101 N·m | 73 ft-lb @ 9,000 r/min |

| Compression Ratio | 11.5:1 | N/A |

| Fuel Tank Capacity | 19 L | 5.0 US gal |

| Overall Length | 2,050 mm | 80.7 in |

The documentation provides guidance on engine, fuel system, cooling system, and more. Maintenance guidelines are included for routine checks and part replacements. OEM guidelines are included for component servicing and adjustment procedures. Transmission service information covers its removal, installation, and inspection. HVAC system procedures are included for system checks. Torque specifications are documented for critical fasteners to ensure proper assembly stress control.

Engine System Overviews

This manual provides extensive documentation on the motorcycle's core systems, including detailed diagrams and part breakdowns. It covers the engine's internal components, fuel delivery, and emission control systems. Careful inspection of these subsystems is crucial for maintaining optimal performance.

Performance Specifications

Key performance data, such as horsepower, torque, and top speed, are detailed within the manual. It also outlines the specific operational parameters for various components, ensuring users understand the intended performance characteristics.

Diagnostic and Repair Procedures

Diagnostic procedures and step-by-step repair instructions are provided for common issues and routine maintenance tasks. The manual emphasizes the use of correct tools and techniques for accurate repairs.

Torque specifications are documented for critical engine and chassis fasteners to ensure proper assembly stress control.

FAQ

Customer Reviews

Read what our customers say about this Kawasaki Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)