1984 Honda ATC Big Red / ATC200ES Service Manual

Covers cylinder head, valves, transmission, crankshaft, and drive system with detailed torque specifications and rebuild procedures for professional mechanics.

Manual Preview

Sample pages from the 1984 Honda ATC Big Red / ATC200ES Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ATC200ES Big Red (ATC200ES) — 1984 Operational Technical Reference | ATC200 Series Compendium.

- Maximum Heat Dissipation Data: 13.0 BHP at 7,000 rpm corresponds to the peak engine horsepower Bounds.

- Universal Production Rate: For optimal cylinder volume, 192 cc (11.7 cu in) sets the single-cylinder displacement Matrix.

- Fundamental Form Factor: The inclined 15° engine arrangement is rated at establishing proper combustion geometry Standards.

- Specific Tightening Data: A compression ratio of 7.8:1 achieves the required combustion pressure Topology.

- Published Gap Specs: Maximum torque yields 1.46 kg·m (1.07 lb-ft) at 5,500 rpm Protocol.

- System Working Temperature: Fuel tank capacity reaches 11.5 liters (3.0 US gal) for extended operation Margin.

Professional Workshop Service Manual & Technical Specifications

Unified Calibration Manual: 1984 Honda ATC Big Red, ATC200ES Service & Repair Assembly-Guide

Engine-Type: 1984 Honda ATC200ES, Honda ATC Big Red // Performance-Values: Engine Systems, Fuel System / Drivetrain Logic // Engine-Type: Complete technical reference material for ATC service operations.

| System Component | Documentation Scope | Coverage Type |

|---|---|---|

| Drivetrain Assembly | Transmission, clutch, gear selection | Complete specifications provided |

| Fuel Delivery | Carburetor components, float level | See Chapter 4 specifications |

| Power Generation | Alternator output, ignition timing | Factory preset parameters documented |

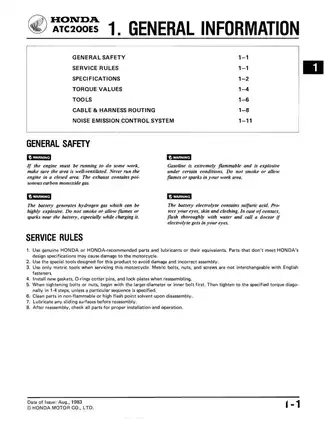

The documentation provides guidance on general information and lubrication fundamentals, incorporates maintenance procedures and service schedules, references fuel system operations and carburetor assembly, and covers cylinder head and valve train architecture. Engine removal and installation requirements are included, along with subtransmission and output gear mechanisms, transmission and crankshaft disassembly references, and front wheel steering assembly procedures.

Structured Standard

Drivetrain specifications are addressed in the transmission sections covering five-speed constant mesh gear selection with reverse operation. Reassembly procedures are specified for manual and centrifugal clutch components, including spring tension documentation and lock nut torque reference data. Service intervals are documented for both lubrication points and major component maintenance. Component locations are identified for brake system assemblies, including drum specifications and shoe wear indicators.

Strategic Architecture

Service procedures are documented for front suspension systems, rear brake mechanisms, and final drive gear assemblies. The manual documents torque specifications for the crankshaft to ensure proper assembly stress control. Final drive components include ring gear tooth contact pattern analysis, backlash measurement methodology, and bearing preload verification. Electrical system schematics present ignition timing values, charging system output ratings, and starter motor specifications.

Engineered Benchmarks

Troubleshooting sections reference compression test procedures, performance diagnostics, and systematic circuit continuity checks. The document references fuel system flow restrictions, carburetor jet sizing parameters, and pilot screw positioning. Valve clearance documentation provides measurement points for both intake and exhaust configurations. Specifications for tire circumference, brake drum inside diameter, and wheel bearing play tolerance are systematically listed.

Diagnostic Standard

Cooling system breather tube routing is included with cable and harness path identification. Spark plug gap measurements and ignition system component replacement procedures are covered. The manual identifies specific tool numbers for specialized service operations, including valve spring compressors, bearing removers, and shaft pullers. Universal joint inspection and drive shaft damper assembly procedures receive detailed documentation.

Systematic Interface

Electrical wiring diagrams present lighting circuits, charging system operation, and starter motor relay configuration. Battery testing procedures reference specific gravity measurements and fluid level inspection protocols. The document includes maintenance schedule tables showing service period intervals and component inspection frequencies. Noise emission control system compliance references federal requirements and component tampering prevention details.

FAQ

Customer Reviews

Read what our customers say about this Honda ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews