Triumph Sprint ST 1050cc / Sprint ST ABS Service Manual

Complete service and repair reference covering engine, transmission, fuel system, suspension, brakes, and electrical components with detailed torque specifications and diagnostic procedures. Part number 3856070.

Manual Preview

Sample pages from the Triumph Sprint ST 1050cc / Sprint ST ABS Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Triumph Sprint ST (1050cc) & Sprint ST ABS — 2007 and earlier Industrial Archive for Motorcycle Unit.

- Maximum Production Rate: 125 PS (123 bhp) is measured at 9,100 rpm establishes the engine output Architecture.

- Universal Physical Specs: 1050 cc represents the total cylinder displacement Protocol.

- Fundamental Output Quality: 105 Nm (77 ft.lbf) at 7,500 rpm is established at peak torque Norms.

- Specific Fill Levels: For optimal fuel storage, 21 litres is set to the tank capacity Bounds.

- Critical Assembly Gap: The compression ratio is configured at 12.0:1 Topology.

- Rated Print Rate: 12V—10 Amp. Hour represents the battery specification Parameters.

Professional Workshop Service Manual & Technical Specifications

Advanced Maintenance Training Manual: Motorcycle 2007 and Earlier Triumph Sprint ST (1050cc) & Sprint ST ABS - Essential Service & Repair Manual Knowledge-Base

Technical-Benchmarks: Triumph Sprint ST (2007 and earlier), Sprint ST ABS (2007 and earlier) // Repair-Classification: Engine, transmission, fuel system, and electrical subsystems Logic // Technical-Domain: Comprehensive service procedures, diagnostic troubleshooting, and component specifications.

| Service-Nexus | Technical-Path | Logic |

|---|---|---|

| Engine Systems | Cylinder head, crankshaft, transmission components | Complete specifications provided |

| Fuel Management | Injection system, throttle bodies, intake air | Electronic control modules documented |

| Electrical Infrastructure | Charging system, ignition, diagnostic circuits | CAN communication protocols included |

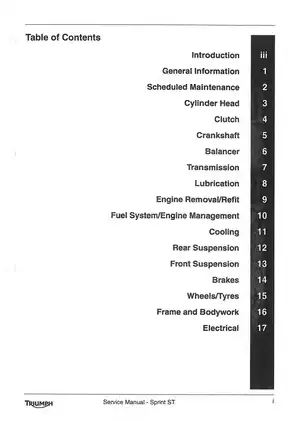

Systematizing the service groups into operational sequences reveals that the document encompasses cylinder head operations through frame assembly procedures. The manual details engine and transmission systems, coordinates fuel system and engine management functions, incorporates cooling and rear suspension guidance, documents front suspension alignment and brake configurations, addresses wheels and tire specifications, and frames electrical diagnostics and secondary air injection controls through comprehensive reference material.

Structured Threshold

Repair information is provided for engine disassembly and crankshaft assembly procedures, covering balancer alignment, bearing selection methodologies, and connecting rod big-end clearance verification. The manual documents torque specifications for the crankshaft main journal assembly to ensure proper structural misalignment prevention. Precise module inspection protocols address visual assessment of camshaft journal wear, clutch friction plate thickness tolerances, and cylinder liner installation techniques.

Modular Architecture

The document includes coverage of transmission shaft disassembly sequences, primary drive gear reduction ratios, and selector drum positioning. Brake system specifications are included for hydraulic caliper piston diameter documentation, disc thickness reference data for both standard and ABS configurations, and master cylinder bore measurements. Safety procedures are documented for initial crankcase separation protocols, bearing shell installation verification, and proper sealing compound application.

Modular Topology

Fluid capacities are listed for engine oil wet and dry fill volumes, transmission lubrication feed specifications, and coolant system volume calculations. The manual provides electrical circuit diagram interpretation guidelines, covering alternator charging system output voltage ranges, starting circuit relay operation logic, and diagnostic trouble code retrieval procedures. Ignition system precautions address high-voltage coil safety, engine stop switch operation, and clutch-dependent starter motor engagement requirements.

Comprehensive Threshold

Engine management system architecture encompasses intake air temperature sensing, manifold absolute pressure monitoring, lambda oxygen sensor feedback integration, throttle position signal processing, and crankshaft position detection methodology. Secondary air injection system operation includes reed valve function, solenoid control logic, and catalyst efficiency protocols. The manual outlines scheduled maintenance intervals for engine oil renewal, filter element changes, spark plug inspection, fuel system pressure verification, and cooling system fluid exchange procedures at defined mileage and time-based checkpoints.

Core Benchmarks

Component inspection procedures document valve clearance measurement techniques, piston ring gap assessment methodologies, and bearing journal diameter verification using precision instruments. The document provides wiring color code reference tables, connector pin numbering systems, and circuit diagram symbol glossaries for electrical troubleshooting. Emission control system documentation includes catalyst positioning, oxygen sensor heater circuit specifications, and evaporative loss control canister operation for California-regulated markets.

Technical Benchmark Data:

Engine displacement reaches 1050 cubic centimeters with bore and stroke dimensions of 79 by 71.4 millimeters. Power output is documented at 125 PS to 2007 model year and 126.5 PS from 2007 model year, with torque specifications recorded at 105 newton-meters at 7500 revolutions per minute. Compression ratio references 12.0 to one, and cylinder head valve configurations detail inlet valve head diameter of 33.5 millimeters and exhaust valve head diameter of 27.0 millimeters. Fuel system operates at 3.0 bar nominal pressure with unleaded 95 RON fuel specification for worldwide markets and 89 CLC/AKI octane rating for United States operation.

Transmission assembly incorporates six-speed constant mesh gearing with first gear ratio of 2.733, second gear 1.947, third gear 1.545, fourth gear 1.292, fifth gear 1.154, and sixth gear 1.074. Final drive ratio is documented at 2.210, with DID X-ring chain specification and 106 link count configuration. Suspension front travel dimension is 120 millimeters, with fork oil volume of 469 cubic centimeters and recommended Showa SS8 grade specification. Rear wheel travel measures 140 millimeters, with Mobil HP 222 grease specification for rear suspension bearing lubrication.

Brake system configuration details twin hydraulic four-piston front calipers with 33.96 and 30.23 millimeter piston diameters acting on dual 320 millimeter discs, and single hydraulic two-piston rear caliper with 27 millimeter piston diameter acting on 220 millimeter disc. Electrical charging system delivers 35 ampere output through alternator assembly, with rectifier-regulator output regulation to 14.5 plus or minus 0.5 volts direct current at battery. Battery specification references YUASA YTX12-BS 12 volt 10 ampere-hour rating.

FAQ

Customer Reviews

Read what our customers say about this Triumph Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)