1987 Husqvarna 154 / 254 Service Manual

Two-stroke chainsaws with electronic ignition, centrifugal clutch, and chain lubrication system. Covers specifications, service procedures, torque values, and troubleshooting for both models.

Manual Preview

Sample pages from the 1987 Husqvarna 154 / 254 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Husqvarna 154, 254 Chainsaw — 1987 Specialized Analytical Compendium | 154/254 Series Segment.

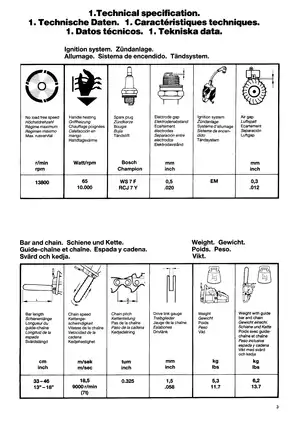

- Calibrated Coupling Torques: 10,000 rpm is calibrated to the maximum engine no-load speed requirement Sequences.

- Certified Twist Specifications: For spark ignition, 0.5 mm (0.020 in) governs the electrode gap measurement Baseline.

- Engineered Holding Capacity: The ignition module requires 0.3 mm (0.012 in) air gap for optimal sensor operation Requirements.

- Primary Load Capacity: 33–48 cm (13–18 in) — is specified as the guide bar length range Threshold.

- General Cycle Rate: Chain velocity reaches 9,000 r/min (7 teeth) at full operating speed Mapping.

- Integral Torque Data: Standard chain pitch is rated at 0.325 in spacing dimension Configuration.

Professional Workshop Service Manual & Technical Specifications

Enhanced Instructional Manual: Chainsaw 1987 Husqvarna 154, 254 Chainsaw - Factory Service & Repair Manual Technical-Repository

Operational-Scope: Husqvarna 154, 254 (1987 models) // Application-Range: Two-stroke engine maintenance and diagnostic troubleshooting logic // Serial-Range: Multi-language technical documentation covering complete service procedures.

| Assessment-Element | Value | Calibration-Data |

|---|---|---|

| Document Type | Factory Service Manual | Comprehensive technical coverage |

| Engine System | Two-stroke, 39-45 cc displacement | Complete ignition and fuel specifications |

| Chain Equipment | 0.325" pitch, 9000-9500 rpm speed range | Guide bar and sprocket documentation |

| Service Data | Torque specifications and fluid capacities | Multi-metric reference tables |

| Safety Features | Chain brake, anti-vibration system, handle heating (G models) | Full assembly and testing procedures |

Technical chapters are organized around fundamental operational requirements. The manual documents engine specifications and centrifugal clutch mechanisms, explores fuel system architecture and carburetor adjustment protocols, covers starter device assembly and electrical ignition systems, and addresses lubrication sequences and oil pump configuration.

Operational Logic-Path

Appropriately requiring comprehensive technical sequences, the manual provides detailed coverage of cylinder and piston assemblies with seizure diagnostics and carbon removal procedures. Crankcase and crankshaft sections include bearing installation, sealing ring positioning, and gasket replacement methodologies. The document includes coverage of vibration dampening equipment, chain brake functionality, and throttle control mechanisms. Safety procedures are documented for brake testing and spark arrester maintenance.

Core Interface

Brake system specifications are included for the automatic activation sequence and manual engagement protocols. The guide bar mounting system receives extensive treatment with bolt replacement techniques and correct orientation procedures. Fluid capacities are listed for fuel, oil, and lubrication reservoirs with tank ventilation testing procedures documented in multiple metric formats.

Strategic Logic-Path

The electrical system sections encompass electronic ignition configuration, spark plug gap verification (0.5 mm standard), and air gap adjustment (0.3 mm) for ignition module positioning. Generator testing with voltmeter protocols is included, along with heated handle system diagnostics for G-model variants. Carburetor rebuild sequences address needle valve inspection, diaphragm replacement, and fuel screen cleaning with detailed pressure testing parameters.

Operational Sequences

Tool requirements are listed for specialist service operations including piston stop tool, pressure gauge assemblies, and crankshaft extraction utilities. The document includes comprehensive troubleshooting matrices cross-referencing 43 diagnostic parameters across starting, idle speed, acceleration, and high-speed performance scenarios. Assembly procedures emphasize component orientation, spring positioning, and dimensional verification throughout.

Integrated Standard

The manual documents torque specifications for the crankshaft assembly to ensure proper joint security and thermal expansion compensation. Multi-language presentation supports English, German, French, Spanish, and Swedish technical audiences with parallel section organization and indexed reference tables.

FAQ

Customer Reviews

Read what our customers say about this Husqvarna Chainsaw manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)