1990 Yanmar 3TG66/3TG72 Gasoline Engine Component Manual

Technical manual covering repair procedures for Yanmar 3TG66 and 3TG72 gasoline engines. Includes detailed diagrams and specifications for optimal engine performance.

Manual Preview

Sample pages from the 1990 Yanmar 3TG66/3TG72 Gasoline Engine Component Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Factory-Level Instructional Workshop Manual: Engines (Gasoline) Technical Yanmar 3TG66/3TG72 Gasoline Engine Component Manual (172 P.) | Workshop Ready Repair-Index

Yanmar Gasoline Engines 3TG66/3TG72 (CTM12) — Series: CTM12 (16MAY90).

- Technical Resolution Data: 0.2 mm (0.008 in.) aligns with the standard valve clearance specification.

- Specific Temperature Range: 71°C (160°F) begins the opening temperature range for the thermostat.

- Essential Power Rating: 1.0 kW signifies the rated output for the Nippon Denso starter specification.

- Advanced Memory Capacity: 0.15 mm (0.006 in.) represents the maximum clearance for piston pin bushings.

- Core Speed Performance: 0.30 mm (0.012 in.) indicates the maximum backlash for the governor gear.

- Integral Lubrication Data: 11 N·m (96 lb-in.) is the specified torque for the oil pump attaching cap screws.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Instructional Workshop Manual: Engines (Gasoline) Technical Yanmar 3TG66/3TG72 Gasoline Engine Component Manual (172 P.) | Workshop Ready Repair-Index

Yanmar Gasoline Engines 3TG66/3TG72 (CTM12) // Series-Validation: CTM12 (16MAY90) / Engine Logic // Serial-Range: 150196.

| Assessment-Element | Parameters | Framework |

|---|---|---|

| Cylinder Head | Max Valve Recession | 0.60 mm (0.024 in.) |

| Rocker Arm | Max Shaft Clearance | 0.12 mm (0.005 in.) |

| Camshaft | Max End Play | 0.5 mm (0.02 in.) |

| Piston | Max Ring Groove Clearance (Top Ring) | 0.25 mm (0.010 in.) |

| Crankshaft | Max End Play | 0.50 mm (0.020 in.) |

| Governor | Governor Gear Backlash (New) | 0.11—0.30 mm (0.004—0.012 in.) |

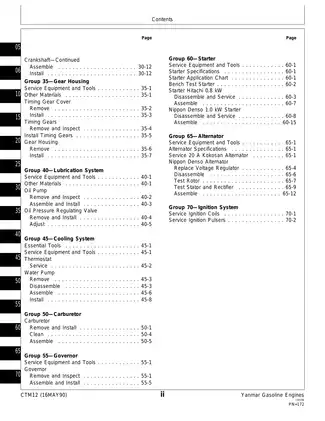

Following OEM groupings, the manual includes sections dedicated to engine repair, system diagnostics, and detailed specifications for Yanmar 3TG66 and 3TG72 gasoline engines. Procedures are outlined for component disassembly and assembly, ensuring clarity for service technicians. It covers essential systems like the valve train, crankshaft, lubrication, cooling, and ignition systems, providing a comprehensive overview of engine maintenance and repair.

Valve Train and Camshaft Procedures

This section documents the systematic approach to servicing the valve train and camshaft components, including detailed steps for measurement, inspection, and assembly, ensuring proper valve clearance and timing.

Crankshaft and Main Bearings Systems

The manual provides in-depth guidance on the crankshaft and main bearings, covering critical aspects such as end play measurement, bearing clearance checks, and oil seal replacement procedures for engine longevity.

Lubrication System Components

Servicing the lubrication system is detailed, including oil pump inspection, rotor recess checks, and oil pressure regulating valve adjustments to maintain optimal engine lubrication.

Cooling System Maintenance

This segment outlines the procedures for maintaining the cooling system, focusing on thermostat testing, water pump disassembly and assembly, and proper coolant levels for engine temperature regulation.

Ignition System Specifications

Key specifications for the ignition system are provided, including servicing procedures for ignition coils and pulsers, ensuring efficient engine combustion and performance.

This manual documents torque specifications for cylinder head cap screws to ensure proper pivot-point integrity.

FAQ

Customer Reviews

Read what our customers say about this Yanmar Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)