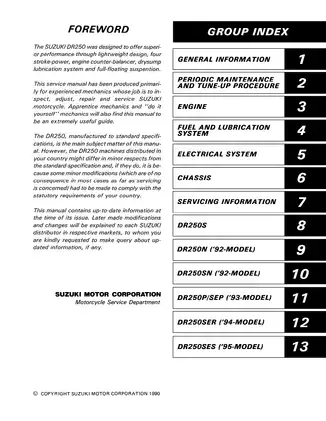

1990-1995 Suzuki DR250 / DR250S / DR250L Service Manual

Documents DR250 series engine procedures, valve clearance 0.05-0.10mm intake / 0.08-0.13mm exhaust, carburetor MIKUNI TM31SS, and complete chassis maintenance with torque specifications. Ref: 99500-42114-03E

Manual Preview

Sample pages from the 1990-1995 Suzuki DR250 / DR250S / DR250L Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki DR250, DR250S, DR250N Series — 1990–1995 Precision Engineering Vault | DR250 Series Repository.

- Calibrated Displacement Data: 249 cm³ (15.2 cu in) is specified as the engine piston volume Architecture.

- Measured Bore Specification: 73.0 mm (2.874 in) represents the cylinder bore diameter Mapping.

- Verified Stroke Length: 59.6 mm (2.346 in) is measured at the crankshaft pin travel Configuration.

- Design Compression Ratio: The cylinder head requires 10.0:1 for standard combustion chamber pressure Benchmarks.

- Engineered Fuel Capacity: Tank volume reaches 9.5 L (2.5 US gal) including reserve Parameters.

- Essential Oil Change Volume: Engine oil capacity is configured at 1,700 ml (1.8 US qt) for standard service Baseline.

Professional Workshop Service Manual & Technical Specifications

Professional Assembly Field Manual: Suzuki DR250 Motorcycle Service Manual 1990-1995 Data-Compendium

Assembly-Group: Suzuki 250, 250S, DR250, DR250S, DR250L, DR250N, DR250SN, DR250P, DR250SEP, DR250SER, DR250SES // Machine-Range: Motorcycle / Dual-Purpose Sportbike Logic // Technical-Scope: Complete service procedures, emissions data, electrical systems, and chassis maintenance.

| Integrated-Framework | Technical-Path | Validation-Data |

|---|---|---|

| Engine Overhaul Components | Disassembly, Inspection, Reassembly Procedures | Chapter 3—Engine section documents complete procedures |

| Emissions & Carburetor Systems | Fuel delivery, mixture control, EPA compliance | Chapters 4 and 8 specify carburetor configurations and regulations |

| Suspension & Brake Assemblies | Front fork, rear shock, disc brake systems | Chapters 6 outlines maintenance intervals and component inspection |

Technical content addresses engine systems and periodic maintenance schedules, carburetor tuning and fuel system design, suspension adjustment and front fork servicing, brake fluid circulation and caliper operation, and electrical systems including ignition timing and charging circuits.

Core Sequences

Maintenance information covers cylinder head procedures and valve clearance specifications, spark plug inspection intervals and heat range selection, brake pad replacement and fluid bleeding sequences, chain tension adjustment and drive sprocket positioning, and steering bearing adjustment with handlebar alignment details. The document includes procedural references for all periodic maintenance at initial 5-hour, 30-hour, and 60-hour service intervals, establishing intervals that apply across all model variants from 1990 through 1995.

Comprehensive Standard

Reference data is included for piston ring end gap measurements and cylinder bore diameter verification, clutch drive plate wear indicators and transmission shift fork clearance specifications, engine mounting bolt torque values and crankshaft bearing preload settings, fuel tank capacity ratings, and engine oil viscosity recommendations for seasonal temperature ranges. Bolt tightening sequences are documented for engine head, cylinder base, and crankcase assembly, with specific values provided in metric and imperial units to facilitate service work across different regional markets and equipment specifications.

Core Threshold

Alignment specifications are included for front suspension preload adjustment and rear shock absorber spring tension settings, camshaft journal oil clearance measurements, and piston-to-cylinder dimensional tolerances. The manual provides detailed rocker arm shaft specifications, conrod deflection limits, wheel rim runout verification methods using dial gauges and magnetic stands. Wiring diagram schematics document the CDI ignition system architecture, lighting circuit configuration with regulator/rectifier integration, and battery charging circuit operation for electrical system troubleshooting.

Integrated Logic-Path

Diagnostic procedures are covered for engine noise identification and carburetor mixture quality assessment, transmission shifting problems and clutch engagement issues, brake system performance evaluation and suspension handling characteristics. Troubleshooting tables address engine starting difficulties, fuel delivery obstructions, spark quality deficiency, and transmission gear engagement failures. The document provides symptom-based guidance for identifying worn piston rings, damaged valve guides, scored cylinder walls, excessive valve clearance, and compromised bearing surfaces through abnormal noise signatures and operational characteristics.

Systematic Benchmarks

This manual documents torque specifications for the primary drive gear to ensure proper threading security, camshaft sprocket bolts to verify correct valve timing alignment, clutch sleeve hub nuts to achieve adequate friction plate compression, and crankcase fasteners to prevent internal oil leakage. Service data tables present specification limits for all internal engine components including valve stem diameters, cam lobe heights, piston pin bore dimensions, and transmission gear ratios with identification numbers. The manual provides comprehensive wiring diagrams with wire color coding, cable routing diagrams with clamp positioning details, and hose routing instructions for fuel, brake, and cooling system installations specific to each model year variant.

NO footer sections, NO generation notices.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)