1996 Yamaha WaveBlaster WB700A/WB700AU Service Manual

Carburetor, fuel pump, and injection system service — plus impeller and reed valve procedures. Complete engine, electrical, and jet pump maintenance with part numbers and torque specs.

Manual Preview

Sample pages from the 1996 Yamaha WaveBlaster WB700A/WB700AU Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha WaveBlaster WB700A — 1996 Advanced Digital Vault | WaveBlaster Series Module.

- Approved Maximum Resolution: 701 cm³ (42.78 cu in) is measured at the engine displacement Architecture.

- Factory Assembly Torques: For peak performance, 47.0 kW (64 hp) @ 6,250 rpm is set to maximum power output Framework.

- Primary Capacity Limits: 69 km/h (43 mph) — limits the maximum speed capability Topology.

- General Energy Draw: The fuel tank capacity requires 25 L (6.6 US gal) for operational standards Matrix.

- Essential Burn-in Temperature: Compression ratio achieves 7.2:1 to maintain combustion chamber pressure Standards.

- Operational Optical Resolution: Battery capacity reaches 12V / 68.4 kC (19 Ah) for electrical system Protocol.

Professional Workshop Service Manual & Technical Specifications

Technical Service Assembly Manual: Yamaha WB700A (R-U) 1996 - Comprehensive WaveRunner Maintenance & Repair Manual Resource-Library

Specification-Class: WB700A (R-U) models 1996 // Operational-Scope: Two-stroke engine and jet propulsion Logic // Specification-Class: 701 cm³ displacement, 73 hp output, water-cooled 2-stroke configuration.

| Component Category | Documentation Level | Reference Scope |

|---|---|---|

| Engine Systems | Complete specifications provided | Chapters 5-6 |

| Fuel & Oil Injection | Torque values and clearance data included | Pages 35-53 |

| Electrical Architecture | Test procedures and component testing | Chapter 7 |

| Jet Pump Unit | Impeller clearance and bearing data documented | Pages 24-30 |

| Hull & Steering | Adjustment procedures and cable routing | Chapter 8 |

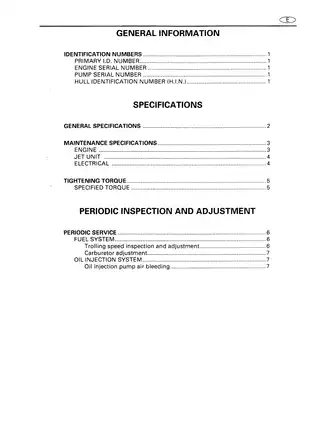

Consistently requiring attention to sequential procedures, this manual provides a comprehensive resource for Yamaha WaveBlaster WB700A service operations. The documentation encompasses Reed valve assembly and cylinder systems, including cylinder head warpage specifications and piston clearance reference data. Cooling system maintenance is addressed throughout dedicated sections covering water jacket cleaning, mineral deposit removal, and thermal switch operation verification. The fuel system data includes carburetor adjustment values, pilot jet and main jet sizing, and float arm height reference measurements. Special procedures are addressed for oil injection system air bleeding, throttle valve synchronization checking, and choke system adjustment processes.

Technical Sequences

Testing requirements are specified for compression pressure evaluation, with baseline readings documented at 940 kPa minimum. The troubleshooting chapter addresses ignition system diagnostics, including spark plug resistance testing and CDI unit functionality verification. Electrical system inspection covers stator coil resistance measurement, charging coil specification testing, and rectifier regulator voltage regulation parameters. Drive unit documentation includes impeller clearance limits and coupling rubber assessment procedures, with run-out tolerance data for intermediate shaft components.

Core Threshold

The manual documents torque specifications for the engine mounting configuration to ensure proper mating surface contact. Component identification sections reference primary ID numbering, engine serial number location, pump serial number placement on intermediate housing, and hull identification number position on the footrest floor. Specifications for the 2-stroke power unit cover bore/stroke dimensions (81 x 68 mm), compression ratio (7.2:1), and reed valve lift measurement data (10.7-11.1 mm).

Technical Sequences

Maintenance hierarchies are structured into periodic inspection intervals spanning initial service through extended operating hours. The manual includes battery fluid level checking procedures, battery specific gravity testing at standard temperature (1.28 at 20°C), and battery charging current specifications. Spark plug gap reference data is provided, with NGK B8HS and BR8HS specifications documented for proper ignition system function.

Core Logic-Path

Jet pump unit assembly includes impeller installation with left-hand thread specifications, drive shaft bearing configuration, and oil seal positioning data. The document provides wiring diagram schematics, cable routing illustrations, and cooling water system flow path documentation. Electrical component specifications include starter motor brush length limits, commutator diameter parameters, and brush holder assembly reference data.

Engineered Framework

Hull and hood systems documentation covers steering system pivot shaft bearing inspection, gunwale attachment specifications, and deck-mounted component installation sequences. The reference includes battery case mounting, fire extinguisher box positioning, and through-hull fitting dimensions. Repair procedures for fiberglass surfaces document sanding progression sequences, gel-coat application methods, and polyester resin curing parameters.

The document includes tightening torque tables for engine mounting bolts (16 Nm), jet pump coupling (37 Nm), and crankcase assembly (28 Nm second step), with specifications provided in newton-meters, meter-kilograms, and foot-pounds. Service point diagrams indicate lubrication locations, grease capacity measurements, and water-resistant grease application areas throughout the engine, jet unit, and steering systems.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)