2002-2003 Bombardier DS 650 ATV Shop Manual

Complete service documentation for DS 650 covering engine diagnostics, carburetor adjustment, transmission repair, and brake system maintenance with detailed torque specifications.

Manual Preview

Sample pages from the 2002-2003 Bombardier DS 650 ATV Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Bombardier DS® 650 (7463, 7527, 7483, 7528, 7484, 7518, 7529, 7519, 7530, 7520, 7587, 7589, 7588, 7590) — 2002–2003 Industrial Applied Repository | DS 650 Series Record.

- Established Assembly Torques: Magneto nut fastener specifications dictate the engine crankshaft securing requirement Margin.

- Measured Liquid Volume: For hydraulic system operation, 1.75 L (0.58 U.S. gal) corresponds to cooling system capacity Protocol.

- Certified Play Limits: Connecting rod big end axial play yields a maximum specification of 0.8 mm (0.031 in) Architecture.

- Factory Temperature Range: The thermostat closes at 95°C (221°F) and opens at 90°C (205°F) for engine cooling Norms.

- Integral Operational Speed: Engine RPM limiter reaches 7900 rpm in any forward gear Bounds.

- Specific Fastener Specs: Wheel nut torque is set to 52.5 N•m (39 lbf•ft) in criss-cross sequence Topology.

Professional Workshop Service Manual & Technical Specifications

Commercial Hydraulic Manual: Bombardier DS 650 ATV Technical-Briefing

Architecture-Focus: DS® 650 (Yellow, Black) 2002-2003, DS® 650 Baja 2002-2003 // Diagnostic-Area: Engine, transmission, fuel system and electrical subsystems // Architecture-Focus: Complete technical specifications with torque data and component reference.

| System Category | Components Covered | Documentation Status |

|---|---|---|

| Engine Assembly | Cylinder head, crankshaft, clutch, transmission | Torque specifications and service limits provided |

| Fuel and Cooling | Carburetor, fuel circuit, radiator, thermostat | Complete reference data included |

| Electrical Integration | Magneto, ignition coils, starter, battery | Testing procedures and wiring diagrams documented |

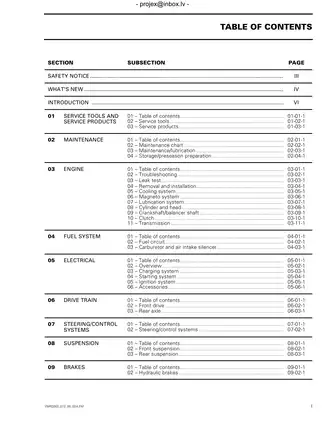

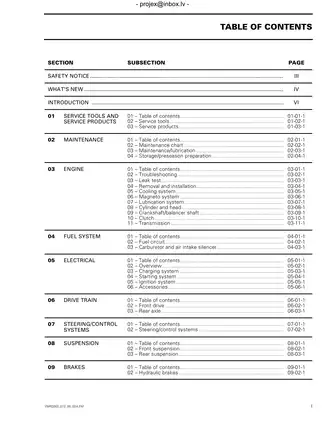

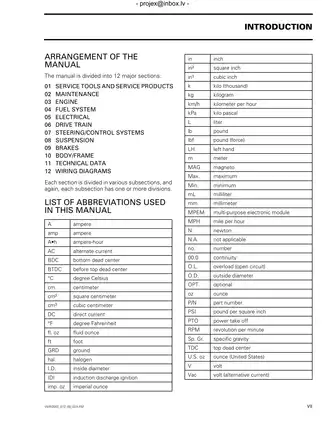

Organized into dedicated modules for Service Tools and Products, Maintenance procedures, Engine systems, Fuel System, Electrical subsystems, Drive Train assembly, Steering and Control mechanisms, Suspension architecture, Braking circuits, Body and Frame construction, Technical Data, and Wiring Diagrams. The documentation addresses Service Tools sections, incorporates Maintenance schedules across seasonal intervals, presents Engine subsystems including cooling and magneto operation, covers Fuel System circuit design, details Electrical configuration with charging and starting protocols, explains Drive Train power transmission, outlines Steering and Control system layout, documents Suspension component configuration, specifies Braking system hydraulic operation, and provides Frame and Body structural information.

Diagnostic Topology

System operation descriptions cover engine mechanical function, transmission engagement sequencing, fuel delivery mechanisms, electrical charging and ignition timing, front and rear suspension articulation, and hydraulic brake force application. The manual provides detailed troubleshooting sections addressing cooling system failures, magneto spark generation, oil pressure anomalies, cylinder and head gasket integrity, crankshaft and balancer alignment, transmission shifting difficulty, engine power loss, and clutch engagement issues. Wear limits are specified for piston rings, valve components, bearing clearances, connecting rod tolerances, clutch friction plates, and brake pad linings to establish service replacement criteria.

Comprehensive Standard

Disassembly instructions are documented for engine removal and installation procedures, carburetor disassembly and cleaning sequences, brake caliper and master cylinder component breakdown, suspension shock absorber spring separation, and frame-mounted accessory extraction. Assembly instructions are detailed for engine installation with proper torque sequencing, carburetor adjustment for float level and pilot screw positioning, brake system bleeding and fluid circulation, suspension component reassembly with preload adjustment, and steering system alignment calibration. The documentation includes exploded view assemblies identifying component relationships, torque value specifications for fastener tightening, Loctite product application procedures, and lubrication point locations.

Engineered Interface

The manual provides comprehensive maintenance intervals organized by operational hours and seasonal usage: initial 10-hour service, 25-hour inspections, 50-hour component evaluation, 100-hour major servicing, and 200-hour complete overhaul cycles. Component reference data identifies service products including threadlocker compounds, pipe sealants, synthetic greases, hydraulic fluids, and coolant specifications. Technical specifications tables document engine displacement of 652 cubic centimeters, compression ratio of 9.7:1, valve timing angles for intake and exhaust, piston clearance tolerances, and crankshaft deflection limits.

Strategic Benchmarks

Front suspension documents double A-arm configuration with 305-millimeter travel, oil-damped shock absorbers, and spring preload adjustment procedures. Rear suspension describes rigid swing arm architecture with 292-millimeter travel, nitrogen-charged shock reservoir, and bearing preload methodology. Electrical system covers magneto generation at 290 watts and 6000 RPM output, CDI ignition type, 13-ampere-hour battery capacity, and 0.9-kilowatt starter motor power rating. Transmission references five-speed constant-mesh design with 3.6:1 rear axle ratio and Regina 530 drive chain specification.

Systematic Protocol

The manual documents torque specifications for the engine support fasteners to ensure proper assembly stress control. Wiring diagrams identify circuit functions for charging system voltage regulation, starting solenoid activation, ignition coil primary and secondary winding operation, brake light switching, and accessory lighting circuits. Component identification includes alternation between Packard and Deutsch connector housing types with pin configuration reference. The documentation addresses component testing procedures including multimeter resistance measurement, oscilloscope signal verification, and pressure gauge functional assessment techniques.

FAQ

Customer Reviews

Read what our customers say about this Bombardier ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)