2005-2007 Bombardier DS650 / DS650 X / DS650 Intl Service Manual

Technical reference for all DS650 configurations, covering maintenance, engine, fuel, electrical, and more. PN 3A5A-X-INTL

Manual Preview

Sample pages from the 2005-2007 Bombardier DS650 / DS650 X / DS650 Intl Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Professional Quality Training Manual: ATV 2005-2007 Bombardier DS650 / DS650 X / DS650 Intl Service Manual Repository Bombardier DS650 / DS650 X / DS650 Intl (3A5A) — 2005–2007 Documentary Dossier & Overview Resource.

- Authorized Design Specs: 35 kPa (5 PSI) is configured at the front tire pressureBenchmarks.

- Published Dimensional Data: For optimal engine operation, 649 cc represents the cylinder displacement capacityBaseline.

- Reference Fluid Parameters: The cooling system is set to maintain 75–100°C (167–212°F) thermostat opening rangeRequirements.

- Fundamental Rotational Speed: Maximum engine speed limits the rated output to 3200 rpmThreshold.

- Specific Storage Capacity: The fuel tank indicates 17 L (4.5 US gallons) storage volumeParameters.

- Core Lubrication Volume: Oil capacity is measured at 1.7 L (1.8 US quarts) engine lubricationThreshold.

Professional Workshop Service Manual & Technical Specifications

Professional Quality Training Manual: ATV 2005-2007 Bombardier DS650 / DS650 X / DS650 Intl Service Manual Repository

| Component-Focus: Bombardier DS650 / DS650 X / DS650 Intl (3A5A) — 2005–2007 // Architecture-Focus: Documentary Dossier & Overview Resource // Component-Focus: ATV | Performance-Element | Diagnostic-Logic | Calibration-Data |

|---|---|---|---|

| Engine Systems | Troubleshooting Procedures | Initial Checks | |

| Fuel System | Carburetor Settings | Fuel Line Diagrams | |

| Electrical Components | Charging System Tests | Ignition Coil Specs | |

| Drive Train Maintenance | Chain Adjustment | Sprocket Wear | |

| Suspension Overhaul | Ball Joint Specs | A-Arm Bushing |

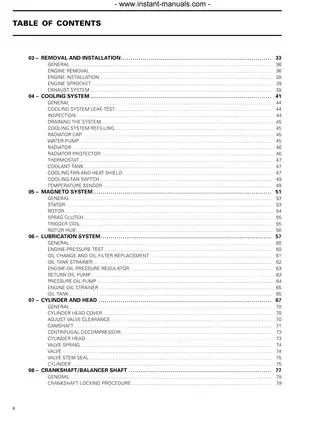

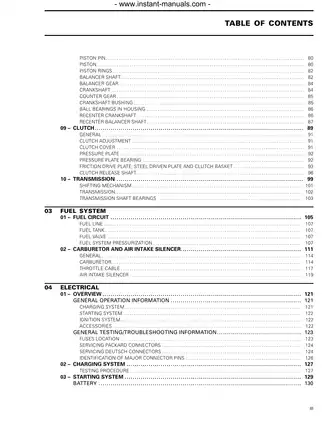

Factory procedures are documented for comprehensive system maintenance, troubleshooting, and repair. This manual covers essential procedures for the DS650, DS650 X, and DS650 Intl models from 2005 to 2007. It provides detailed schematics and step-by-step instructions for all major systems, including engine, transmission, suspension, and electrical components. Specific attention is given to diagnostic routines and part replacement guidelines, ensuring that repairs are performed correctly and efficiently for optimal performance and longevity. The document includes torque specifications for various components to ensure proper assembly and corrosion joint prevention.

Engine Systems Documentation

This section documents engine maintenance, troubleshooting, and repair procedures, covering critical areas such as cylinder head, crankshaft, and lubrication systems. It details the necessary steps for disassembly and reassembly, providing torque values and specific instructions for each component to guarantee correct installation and prevent potential damage. The manual emphasizes the importance of using the correct parts and procedures to maintain engine integrity and performance.

Fuel System Procedures

Explore detailed procedures for the fuel system, including fuel tank, fuel valve, and carburetor maintenance. The manual outlines steps for fuel system pressurization, leak testing, and carburetor adjustments. It provides guidance on float level settings and throttle cable adjustments, crucial for achieving optimal engine efficiency and performance. Proper fuel system maintenance ensures reliable operation and prevents common issues like fuel leaks or poor engine calibration.

Electrical System Components

This part of the manual details the electrical system, covering charging, starting, and ignition systems. It includes diagnostic procedures for various electrical components like the battery, ignition switch, and starter motor. The document provides resistance measurements and voltage tests to identify faulty parts. Proper electrical system maintenance is vital for reliable vehicle operation and preventing electrical failures. The manual guides users through troubleshooting common electrical issues, ensuring all connections are secure and components function as intended.

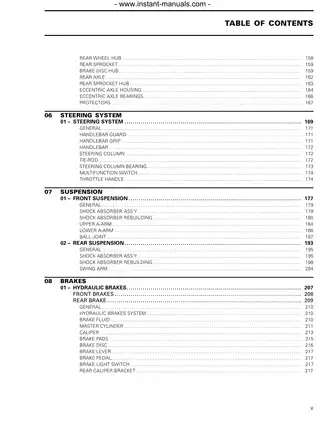

Drive Train and Suspension Maintenance

Focus is placed on drive train components, including the clutch, transmission, and rear axle systems. Procedures for adjusting the drive chain, maintaining sprockets, and inspecting various hubs and bearings are thoroughly explained. The suspension system, covering front and rear components like A-arms and shock absorbers, is also detailed, offering guidance on removal, disassembly, and adjustment. Correct maintenance of these systems ensures smooth power delivery and optimal handling characteristics for the ATV.

Steering and Braking System Servicing

This section covers the steering system, including handlebar, steering column, and tie-rod maintenance. It provides detailed instructions for inspecting and adjusting components to ensure precise steering control and stability. The braking system is also addressed, with procedures for maintaining brake fluid, calipers, and pads. Proper upkeep of the steering and braking systems is paramount for rider safety and confident control of the vehicle under various conditions. This manual documents torque specifications for ensuring proper assembly and corrosion joint prevention.

FAQ

Customer Reviews

Read what our customers say about this Bombardier ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)