1999 Honda CB1100SF Service Manual

Complete 200-page service guide covering maintenance, fuel injection (PGM-FI), engine specifications, cooling system, and brake procedures. Factory documentation for precision CB1100SF repair and rebuild.

Manual Preview

Sample pages from the 1999 Honda CB1100SF Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda CB1100SF — 1999 Consolidated Mechanical Index | CB1100SF Series Record.

- Prescribed Thermal Rating: Engine coolant capacity reaches 3.2 L (3.4 US qt) is designed for the liquid cooling system Architecture.

- Documented Feed Speed: Oil pressure achieves 490 kPa (5.0 kgf/cm², 71 psi) at 5,400 rpm controls the main journal bearing flow Norms.

- Maximum Footprint Data: Dry weight totals 222 kg (489 lbs) is measured at the frame assembly Bounds.

- System Securement Values: The fuel tank capacity requires 22 L (5.8 US gal, 4.8 Imp gal) for standard operation Topology.

- Technical Clearance Data: Valve clearance specifications indicate 0.16 + 0.03 mm (0.006 + 0.001 in) intake delivers proper engine performance Matrix.

- Advanced Climate Parameters: Compression ratio achieves 11.2:1 pressure is specified as the combustion efficiency standard Standards.

Professional Workshop Service Manual & Technical Specifications

Precision Troubleshooting Reference Manual: Honda CB1100SF (1999)

Repair-Classification: CB1100SF (1999) // Service-Level: Programmed Fuel Injection / Engine Systems Logic // Repair-Classification: Four-cylinder inline 1,137cc configuration with DOHC valve train.

| Assessment-Parameter | Value | Calibration-Spec |

|---|---|---|

| Document Coverage | General information through electrical systems | 20 major sections documented |

| System Categories | Engine, fuel injection, cooling, transmission | Complete specification references included |

| Component Scope | Lubrication, chassis, brake hydraulics | Technical data provided throughout |

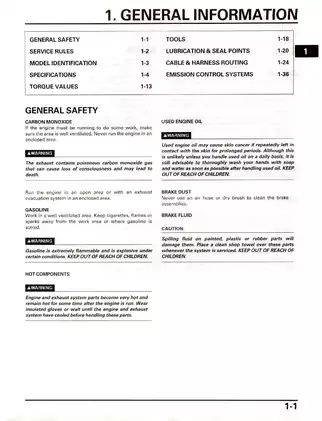

Following OEM groupings, the manual includes Lubrication System documentation, Fuel System procedures covering PGM-FI diagnostics, Cooling System protocols, and Chassis suspension guidance, describing systems integration, explaining component relationships, documenting electrical architecture, and covering Frame assembly procedures through troubleshooting methodology.

Engineered Interface

This manual covers the complete 1999 Honda CB1100SF platform with detailed system organization. The document describes engine architecture featuring a 79.0 × 58.0 mm bore and stroke configuration with forced-pressure lubrication and dual-overhead camshaft valve timing. Fuel system data is documented extensively for the Programmed Fuel Injection system, including throttle body identification numbers and idle speed specifications. The manual provides wiring diagrams for electrical integration and system location references for all major components.

Precise Parameters

Diagnostic procedures are covered for malfunction indicator failure codes with self-diagnosis reset sequences. The document includes specifications for cylinder compression testing, valve clearance reference data, and clutch operation parameters. Comprehensive torque specifications are documented for fastener applications throughout engine, frame, and chassis subsystems. Sensor resistance measurements at 20°C are provided for intake air temperature, engine coolant temperature, fuel injector, and PAIR solenoid valve components, ensuring reference accuracy during inspection and troubleshooting.

Advanced Framework

Wiring diagrams are provided for the main harness routing, PAIR control systems, and electrical connector locations. The manual documents fuel system component assembly procedures with emphasis on seal ring and O-ring replacement protocols. Cooling system procedures are covered including thermostat valve lift specifications and radiator capacity data. Brake system documentation describes both front and rear hydraulic configurations with caliper cylinder specifications and master cylinder bore measurements.

Core Benchmarks

Fuel system troubleshooting is detailed for starting difficulties, rough idle conditions, and acceleration performance issues. The document includes PGM-FI system self-diagnosis procedures with malfunction indicator interpretation guidelines. Maintenance schedule intervals are documented with frequency references for oil changes, air filter replacement, brake fluid service, and suspension inspection. Drive chain adjustment slack specifications and brake pad wear indicator thresholds are included with reference marking information.

Systematic Protocol

Adjustment procedures are detailed for engine idle speed using the throttle stop screw methodology. Valve clearance inspection and adjustment sequences are documented with specific feeler gauge specifications and shim thickness calculation formulas. The manual describes spark plug gap inspection using wire-type feeler gauges and specifies CR8EHVX-9 plug designation for this platform. Starter valve synchronization procedures are covered with intake vacuum pressure measurement guidance and idle speed verification protocols.

The manual documents torque specifications for bolt fastener applications to ensure proper assembly and rotational loosening prevention, with specific attention to flange bolt sequences, locking agent application points, and sealing washer replacement requirements throughout the engine, transmission, and frame systems.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)