2006-2013 Triumph Tiger 1050 ABS Service Manual

Service procedures for engine, transmission, cooling system, fuel injection — all three-cylinder models. Complete coverage of the Tiger 1050 and Tiger 800 variants with electronic fuel management, ABS braking, and chassis components from factory documentation.

Manual Preview

Sample pages from the 2006-2013 Triumph Tiger 1050 ABS Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Triumph Tiger 1050 (ABS) — 2006–2013 Licensed Strategic Repository | Tiger Series Section.

- Designated Power Framework: 115 PS (114 bhp) at 9,400 rpm is calibrated to maximize engine output Benchmarks.

- Primary Operating Temps: For optimal function, the coolant thermostat opening temperature is specified as 85°C nominal Range.

- Advanced Cycle Rate: The engine displacement reaches 1050 cc (64 cu in) and governs the three-cylinder configuration Sequences.

- Design Package Size: The fuel tank capacity requires 20 litres (5.3 US gal) for standard highway operation Baseline.

- Engineered Moment Values: The maximum torque output is rated at 100 Nm (74 ft-lb) at 6,250 rpm Requirements.

- Certified Current Rating: The alternator provides 34A charging capacity to support the 12V 10 Amp-Hour battery Threshold.

Professional Workshop Service Manual & Technical Specifications

Detailed Installation Manual: Triumph Tiger 1050 (ABS) Repository

Component-Focus: Triumph Tiger 1050 (2006-2013), Tiger 800 (2006-2013) // Reference-Category: Electronic Control Module / Fuel Delivery Logic // Component-Focus: Crankshaft positioning, Torque documentation, Sensor networks.

| System Documentation | Coverage Scope | Reference Details |

|---|---|---|

| Engine & Transmission | 3-cylinder, 1050cc displacement, 6-speed transmission | Complete specifications provided |

| Electrical Architecture | CAN-bus communication, ECM integration, ABS modulation | Documented throughout sections |

| Diagnostic Capabilities | On-board fault detection, DTC logging, freeze-frame capture | See diagnostic tool section |

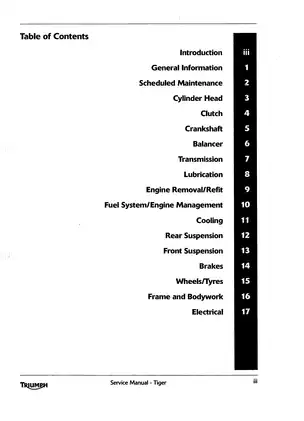

Factory procedures are documented for cylinder head servicing, transmission disassembly and reassembly, crankcase separation and joining, then covers engine mounting, fuel system architecture, and cooling circuit procedures; additionally presents secondary air injection operation, clutch cable adjustment methodology, and brake system maintenance protocols.

Integrated Logic-Path

Electrical system documentation covers the ignition architecture, starter motor circuit topology, alternator charging system operation, and battery management. The manual includes detailed ignition coil specifications, fuel pump relay configuration, and engine control module pin assignments. Lambda sensor operation and oxygen feedback systems are described, together with throttle position sensor calibration data and crankshaft position detection methods.

Technical Logic-Path

Suspension service documentation covers fork oil types, rear damper mounting brackets, and wheel bearing extraction procedures. Brake system information includes caliper piston dimensions, disc thickness wear limits, and master cylinder specifications. The document references ABS system modulation, speed sensor placement, and anti-lock brake component locations throughout the assembly sections.

Comprehensive Logic-Path

Disassembly instructions are documented for pistons and connecting rods, including gudgeon pin removal techniques, circlip handling, and piston ring gap verification. The manual provides balancer shaft assembly sequences, crankshaft bearing selection charts, and connecting rod bearing clearance measurement protocols using Plastigage methodology.

Comprehensive Threshold

Wear limits are specified for valve stem diameters, seat widths, and guide bore tolerances. Cylinder bore measurement procedures, piston skirt dimensions, and ring gap specifications are included. The document also contains connecting rod big-end bearing clearance ranges and crankshaft journal diameter service limits for proper component selection and assembly verification.

Precise Architecture

System operation descriptions cover fuel injection timing, ignition advance calculations, and manifold absolute pressure sensor integration. The manual documents torque specifications for the cylinder head to ensure proper gasket sealing, connecting rod assembly integrity, and crankcase joint reliability throughout engine construction.

FAQ

Customer Reviews

Read what our customers say about this Triumph Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)