Kubota L185-L355 Tractor Shop Manual 1976-1985

Kubota L185-L355 series tractor troubleshooting and repair reference, covering engine, transmission, hydraulics, and more. Includes part numbers and diagrams. Ref: Z751A

Manual Preview

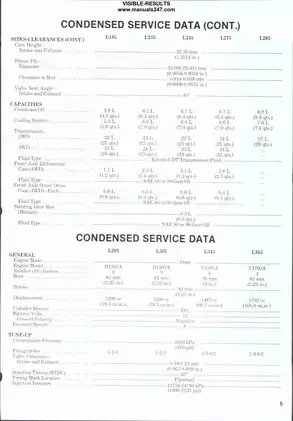

Sample pages from the Kubota L185-L355 Tractor Shop Manual 1976-1985 manual

Purchase & Download

Models Covered & Key Technical Specifications

Kubota L185/L235/L245/L275/L285/L295/L305/L345/L355 (Z751A) — 1976–1985 Diagnostic Briefing for L-Series Compact Tractors

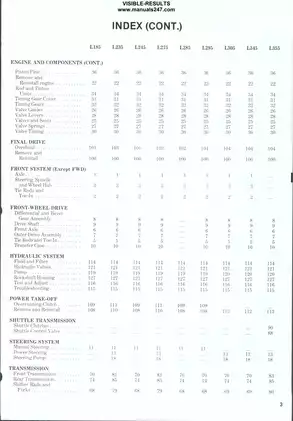

- Documented Technical Data: 743 cc (45.3 cu.in.) engine displacement as the baseline cylinder volume Specifications.

- Calibrated Power Rating: Rated Power at PTO Shaft is 11.5 kW (15.45 HP) as the active printing consumption Threshold.

- Rated RPM Specifications: Maximum rated engine speed achieves 2950 rpm (high idle) on Models L185, L245, and L295 throughout complete operating Threshold.

- Principal Specifications: Valve clearance sets 0.18–0.22 mm (0.007–0.009 inch) for both intake and exhaust valve actuation Parameters.

- Documented Injection Pressure: Injection pressure defines 13720–14700 kPa (1990–2135 psi) injection system threshold Requirements.

- Design Voltage Specifications: System pressure reaches 13240–14690 kPa (1920–2130 psi) hydraulic relief setting across all tractor Configuration.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Engineering Installation Manual: Kubota L185/L235/L245/L275/L285/L295/L305/L345/L355 Shop Manual Blueprint-Vault

Serial-Range: 1976-1985 // Technical-Benchmarks: L185 / L235 / L245 / L275 / L285 / L295 / L305 / L345 / L355 // Component-Focus: Engine and Transmission

| Component | Value | Validation-Data |

|---|---|---|

| Engine Make | Kubota | General Data |

| Bore | 76 mm (3 in.) | Standardized Measurement |

| Displacement | 743 cc (45.3 cu.in.) | Engine Specification |

| Compression Pressure | 3,235 kPa (470 psi) | Tune-Up Value |

| Rated Power at Pto Shaft | 11.5 kW (15.45 HP) | Performance Metric |

| Crankshaft Main Journal Diameter | 51.921–51.940 mm (2.0441–2.0449 in.) | Component Dimension |

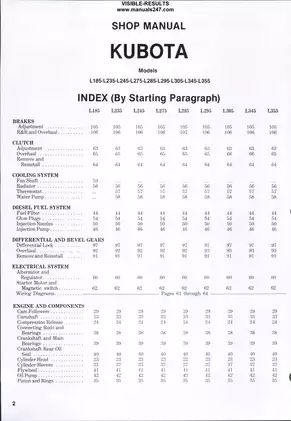

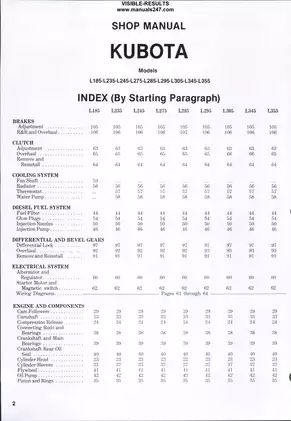

Documentation sections include troubleshooting, engine components, front axle, hydraulic system, steering system, transmission, and detailed wiring diagrams for comprehensive tractor operation. The manual covers practical maintenance procedures for a wide range of systems, ensuring optimal performance and longevity. This guide details specific torque specifications for engine components to ensure proper service interval reliability.

The document includes coverage of the engine and its major components, providing detailed R&R procedures and exploded views. Brake system specifications are included for various models, outlining adjustment and maintenance steps. Safety procedures are documented throughout the manual to ensure user protection during all operations. Fluid capacities are listed for all transmission and hydraulic systems, simplifying fluid replacement. Tool requirements are listed for specialized tasks, ensuring users have the necessary equipment.

FAQ

Customer Reviews

Read what our customers say about this Kubota Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)