1986-2001 Honda XL600 Transalp Repair Manual

Technician-level documentation for v-twin engines with fuel systems, cooling, electrical, carburetor tuning specs and torque values. Complete service procedures.

Manual Preview

Sample pages from the 1986-2001 Honda XL600 Transalp Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda XL600 Transalp — 1986–2001 Systematic Technical Reference | XL600 Series Kit.

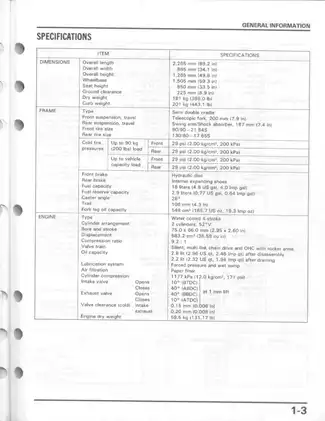

- Approved Assembly Torques: 110 N·m (11.0 kg-m, 80 ft-lb) corresponds to the swingarm/engine pivot nut fastening requirement Margin.

- Baseline Liquid Volume: For optimal lubrication, 583.2 cm³ (36.59 cu in) sets the engine displacement Architecture.

- Primary Play Limits: Valve clearance is rated at intake 0.15 mm (0.006 in) and exhaust 0.20 mm (0.008 in) Protocol.

- General Temperature Range: Compression pressure achieves 1177 ± 98 kPa (12.0 ± 1.0 kg/cm², 171 ± 14 psi) Norms.

- Essential Operational Speed: Idle speed determines 1,300 ± 100 rpm engine performance Bounds.

- Operational Fastener Specs: The fuel tank capacity yields 18 liters (4.8 US gal, 4.0 Imp gal) storage Topology.

Professional Workshop Service Manual & Technical Specifications

Professional Operations Overhaul Manual: Motorcycle Shop-Grade Honda XL600 Transalp - Comprehensive Service & Repair Guide (1986-2001) Service-Portfolio

Conceptual-Layout: Honda XL600 Transalp (1986-2001) // Engineering-Metrics: V-twin engine logic, dual-cylinder system // Conceptual-Layout: 200-page technical resource with torque specifications and component assembly procedures.

| Identifier | Diagnostic-Logic | Validation-Data |

|---|---|---|

| Engine Systems | Compression testing, valve timing data | Specifications documented, 1177 kPa standard |

| Chassis Assembly | Drive chain, suspension mechanics | Service limits and adjustment procedures included |

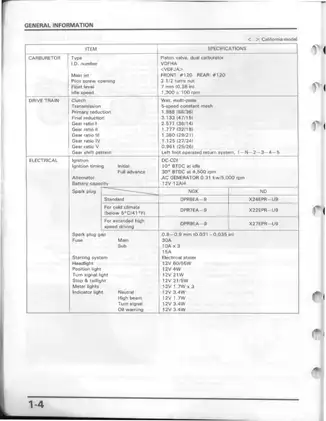

| Electrical Components | Ignition timing, starter clutch operation | Alternator output and battery capacity referenced |

| Brake Systems | Hydraulic and mechanical brake documentation | Fluid specifications and pad wear limits provided |

| Transmission | 5-speed constant mesh gearbox | Gear ratio and shift fork specifications detailed |

Major sections focus on engine removal and reinstallation procedures, cylinder head and valve servicing, and complete clutch and gearshift linkage assembly, while detailed coverage addresses fuel system configuration, cooling system maintenance, and comprehensive brake system documentation, complemented by front and rear suspension adjustment protocols, electrical system diagnostics, and cowling component installation guidance.

Modular Sequences

Special procedures are addressed for crankcase separation, bearing replacement, and connecting rod installation. The manual documents torque specifications for the crankshaft assembly to ensure proper component alignment retention. Comprehensive coverage includes main bearing oil clearance inspection using plastigauge methodology, connecting rod big-end measurements, and crankpin bearing selection by color-coded classification systems.

Comprehensive Protocol

Verification procedures are included for valve clearance adjustment, carburetor synchronization, and cooling system pressure testing. Reference chapters include radiator cap relief pressure validation, thermostat operation confirmation at specified temperature thresholds, and thermosensor resistance measurement across multiple temperature conditions. The document provides detailed cable and harness routing diagrams with specific component identification for both standard and California emissions control variants.

Precise Methodology

Repair information is provided for hydraulic brake systems, including master cylinder bore measurements, brake caliper piston specifications, and disc thickness service limits. Comprehensive assembly data covers brake pad replacement procedures, brake fluid compatibility requirements (DOT 3 or 4), and air-bleeding sequences. The manual details suspension geometry through fork leg fluid capacity specifications, spring free length documentation, and shock absorber compression force verification at established measurement points.

Operational Framework

The document includes coverage of wheel and tire specifications, including rim runout limits for both radial and axial measurements at front and rear positions. Spoke tension documentation references standard torque values for wheel assembly security. Bearing replacement procedures detail bearing driver attachment specifications and pilot dimensions for both front and rear wheel hubs, with emphasis on sealed bearing installation orientation.

Modular Nexus

Brake system specifications are included for rear drum internal-expanding shoe assemblies, with documentation of lining thickness service limits and drum inside diameter maximum wear parameters. The manual addresses both front hydraulic disc brake and rear mechanical brake documentation, including brake light switch adjustment procedures and pedal free play measurement references. Special attention covers emission control system components for California-certified models, including evaporative emission control system purge valve inspection and charcoal canister routing verification.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)