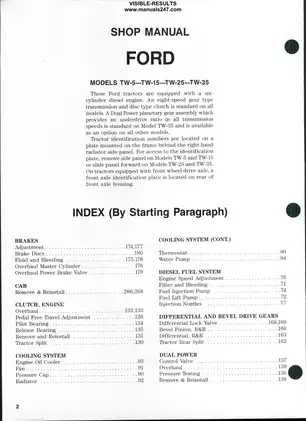

1983-1989 Ford TW-5 / TW-15 / TW-25 / TW-35 Tractor Shop Manual

Ford TW-5, TW-15, TW-25 & TW-35 diesel tractor service procedures — engine overhaul, transmission repair, hydraulic lift systems, PTO clutch, differential lock, and complete powertrain diagnostics for 1983-1989 models.

Manual Preview

Sample pages from the 1983-1989 Ford TW-5 / TW-15 / TW-25 / TW-35 Tractor Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ford TW-5, TW-15, TW-25 & TW-35 — 1983–1989 Precision Engineering Vault | TW Series Compendium.

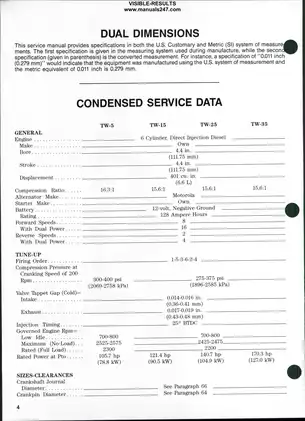

- Calibrated Displacement Data: 401 cu. in. (6.6 L) is measured at the six-cylinder diesel engine displacement Architecture.

- Rated Power Output: 105.7 hp (78.8 kW) represents the TW-5 engine horsepower at 2300 rpm rated load Topology.

- Critical Compression Ratio: 15.6:1 — is established at the standard TW-5 combustion chamber pressure Matrix.

- Universal Valve Clearance: The intake valve requires 0.014-0.016 in. (0.36-0.41 mm) cold lash setting Standards.

- Core Amperage Specs: Battery capacity produces 128 Ampere Hours at the 12-volt negative ground system Margin.

- Standard Feed Speed: Engine idle speed is configured at 700-800 rpm for all TW models Protocol.

Professional Workshop Service Manual & Technical Specifications

Strategic Wiring Manual: Ford TW-5, TW-15, TW-25 & TW-35 Tractor Shop Manual Chassis-Documentation

Product-Line: Ford TW-5, TW-15, TW-25, and TW-35 models (1983-1989 production years, including Mark II variants) // Subsystem-Focus: Engine, transmission, and hydraulic system documentation / Complete powertrain and operational procedures // Product-Line: Comprehensive diesel engine and integrated mechanical systems reference.

| Documentation Section | Primary Coverage | Available Details |

|---|---|---|

| Engine Systems | Six-cylinder diesel powerplant with direct injection | Specifications and component documentation included |

| Transmission Assembly | Eight-speed constant-mesh gearbox with Dual Power planetary option | Service procedures and adjustment data provided |

| Hydraulic Systems | Lift control, power steering, and brake circuits | Operational parameters and troubleshooting guides documented |

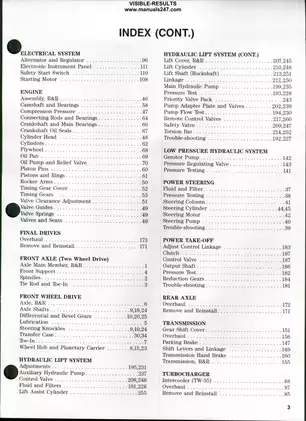

Repair procedures are structured around engine and transmission systems, covers brakes and clutch assemblies, addresses hydraulic lift functionality, and includes power take-off and differential components. The manual encompasses front axle configurations (both two-wheel and four-wheel drive options), steering system architecture, and electrical system monitoring, continuing with final drive mechanisms and associated control systems.

Operational Architecture

Tool requirements are listed for engine service operations. The document includes wiring schematics for the electronic instrument panel monitoring system, which displays engine temperature, oil pressure, transmission conditions, fuel status, and ground speed. Installation guidelines are provided for major component replacement procedures, including engine removal and reinstallation sequences, transmission separation methods, and rear axle assembly procedures. Reference data is documented for crankshaft, camshaft, and bearing journal dimensions.

Systematic Benchmarks

Maintenance guidelines are included for cooling system maintenance, fuel system servicing, and transmission fluid renewal intervals. Valve clearance reference data is included for intake and exhaust valve adjustment on all models. Specification tables document compression pressure ranges, timing relationships, and bearing clearance parameters required for proper assembly. The manual provides documentation of torque specifications for the engine block fasteners to ensure proper load distribution.

Systematic Benchmarks

OEM guidelines are included for clutch pedal adjustment procedures, brake system bleeding methods, and power steering fluid servicing. Electrical system components are documented, including alternator output testing, battery voltage verification, and starting motor performance parameters. Transmission overhaul procedures reference shift linkage geometry, bearing preload methodology, and output shaft alignment requirements.

Advanced Protocol

Transmission service information covers eight-speed transmission disassembly, countershaft gear arrangement, and shift fork positioning. The document references carrier bearing adjustment procedures for the main drive bevel pinion assembly. Hydraulic system schematics show relief valve integration, pressure regulating valve operation, and remote control valve priority sequencing. Pto clutch assembly documentation includes friction plate configuration and brake pad replacement guidance.

Systematic Logic-Path

Front axle service procedures are documented for multiple configurations, including APL-345, APL-355, APL-3054, and APL-365 type axles used across model years. Differential assembly overhaul procedures are included with backlash measurement methodology and bearing preload calculation techniques. The manual documents torque specifications for the differential carrier fasteners to ensure proper load distribution across bearing surfaces.

Comprehensive Coverage: Factory diagnostic procedures, component identification, and system operation principles are provided throughout this 163-page reference manual, supporting service on 1983-1989 Ford TW series tractors across all four displacement and power configurations.

FAQ

Customer Reviews

Read what our customers say about this Ford Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)