Kawasaki KF82/KF100/KF150 4-Stroke Air-Cooled Gasoline Engine Workshop Manual

Kawasaki KF Series engines: procedures for engine control, carburetor, ignition system, and governor. Includes specs and troubleshooting for KF82, KF100, KF150. Part No. 99924-2006.

Manual Preview

Sample pages from the Kawasaki KF82/KF100/KF150 4-Stroke Air-Cooled Gasoline Engine Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kawasaki KF82/KF100/KF150 Engine Workshop Manual Kawasaki KF82/KF100/KF150 (99924-2006) -- Air-Cooled 4-Stroke Engine Service Manual | Engine Compendium.

- Prescribed Fluid Capacity: 6.5 L is designed for the fuel tank capacity on KF82 models Standards.

- System Fill: For optimal operation, 8 L is configured at the fuel tank capacity for KF100 models Topology.

- Core Ambient Limits: 10.5 L -- signifies the fuel tank capacity for KF150 models Matrix.

- Rated Dimensional Limits: The cylinder bore requires 80 mm for the KF82 model Standards.

- Technical Assembly Gap: The piston displacement requires 397 cc for the KF100 model Margin.

- Advanced Locking Torques: The dry weight provides 67.5 kg for the KF150 model Protocol.

Professional Workshop Service Manual & Technical Specifications

Practical Troubleshooting Engine Manual: Kawasaki KF82/KF100/KF150 Engine Workshop Manual - Air-Cooled 4-Stroke Procedures Factory-Standards

| Engine-Type: Air Cooled, 4-stroke, single cylinder, gasoline engine // Assembly-Group: Engine // Engine-Type: KF82, KF100, KF150 Logic. | Performance-Element | Technical-Path | Calibration-Data |

|---|---|---|---|

| Engine Type | Air Cooled, 4-stroke, single cylinder, gasoline engine | ||

| Bore x stroke | KF82D: 80 x 68 mm | KF100D: 85 x 70 mm | KF150D: 95 x 82 mm |

| Piston Displacement | 341 cc | 397 cc | 581 cc |

| Maximum Output | 8.2 hp/4,000 r.p.m. | 10 hp/3,600 r.p.m. | 14 hp/3,600 r.p.m. |

| Dry Weight | 40 kg | 40 kg | 67.5 kg |

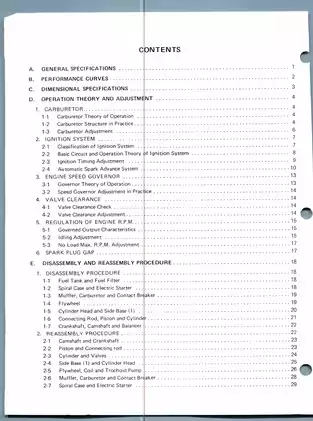

Featuring a modular arrangement of comprehensive system operation descriptions, this manual provides detailed insight into the architecture of the Kawasaki KF series engines. It covers essential aspects from basic specifications and performance curves to dimensional data, ensuring a complete understanding of engine mechanics.

System operation descriptions cover engine theory, carburetor functions, and ignition system principles. Detailed explanations are provided for the Electronic Ignition System, Automatic Spark Advance, and Electric Starter systems, offering a clear view of their operational logic and integration within the engine.

Assembly instructions are detailed for components such as the cylinder head, piston, connecting rod, crankshaft, flywheel, and starter motor. The manual guides users through the entire disassembly and reassembly process, emphasizing critical steps and component placements for successful engine repair.

Hydraulic schematics are included for understanding fluid dynamics and lubrication systems. Information on governor theory, valve clearance adjustment, and spark plug gap settings is also provided, contributing to optimal engine performance and longevity.

Steering component information is provided for troubleshooting common engine malfunctions. The manual addresses issues related to low power, hard starting, high-speed hunting, and excessive fuel or oil consumption, offering systematic diagnostic procedures and corrective actions.

The documentation addresses torque specifications for various components, including cylinder head bolts and flywheel nuts, to ensure proper rotational loosening prevention and structural integrity of the engine assembly.

FAQ

Customer Reviews

Read what our customers say about this Kawasaki Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)