Stihl FS 160, 180, 220, 280 Clearing Saw Service Manual 1989-04

Technical reference for Stihl FS 160, 180, 220, 280 models. Includes diagrams, specifications, and repair procedures. PN 0000 961 0608.

Manual Preview

Sample pages from the Stihl FS 160, 180, 220, 280 Clearing Saw Service Manual 1989-04 manual

Purchase & Download

Models Covered & Key Technical Specifications

Stihl FS 160, 180, 220, 280 (1989-04) — Series: 1989–2002 Full Coverage: FS 160, FS 180, FS 220, FS 220 K, FS 280, FS 280 K.

- Engine Displacement: 29.8 cm³ to 38.9 cm³ displacement parameters define the single-cylinder two-stroke architecture with special impregnated cylinder bores.

- Torque Specifications: 24.0 Nm (18 lbf.ft) M8x1 hexagon nut logic must be applied to the crankshaft flywheel and starter side fasteners.

- Ignition Gap: 0.5 mm (0.020 in) electrode gap parameters are mandated for NGK BPMR 7 A or Bosch WSR 6 F ignition framework.

- Fuel Mixture Ratio: 40:1 mix ratio logic required for regular grade gasoline and STIHL two-stroke engine oil parameters.

- Service Tool Part ID: 5910 890 2210 installing tool logic is required to fit hookless snap rings into the piston boss architecture.

- Ignition Timing: 0.15–0.25 mm (0.006–0.010 in) air gap logic established for the electronic breakerless magneto ignition framework.

Professional Workshop Service Manual & Technical Specifications

Verified Quality Repair Manual: Stihl FS 160, 180, 220, 280 Clearing Saw Service Manual (1989–04) – 157 Pages | Ready to Print Documentation-Framework

| Model-Designation: FS 160, 180, 220, 280 (1989-04) // Asset-ID: 4134 // Technical-Benchmarks: 29.8 cm³ - 38.9 cm³ Displacement OEM guidelines are included for all servicing procedures and repairs. Transmission service information covers clutch and gearhead assemblies. HVAC system procedures are included for carburetor and fuel system maintenance. Torque specifications are documented for critical fasteners to ensure proper assembly integrity. Parts identification is covered for all components including special accessories. | Component | Parameters | Calibration-Spec |

|---|---|---|---|

| FS 160 | Displacement: 29.8 cm³ | 0.6 bar (8.7 psi) | |

| FS 180 | Displacement: 35.2 cm³ | 0.6 bar (8.7 psi) | |

| FS 220 | Displacement: 35.2 cm³ | 0.4 bar (5.8 psi) | |

| FS 280 | Displacement: 38.9 cm³ | 0.4 bar (5.8 psi) |

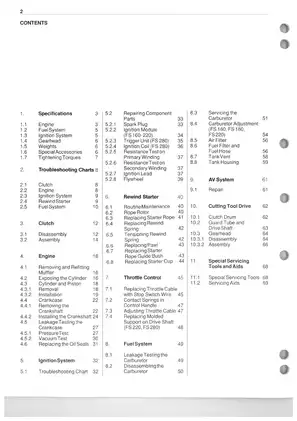

Cataloging major assemblies into their respective sections, this manual provides comprehensive documentation.

Procedures and Component Identification

This manual details the process for disassembly and assembly of key components including the engine, fuel system, ignition system, and clutch.

System Overviews and Maintenance

Service information covers the carburetor, air filter, fuel tank, and starter assembly for thorough maintenance.

Tightening Torques and Specifications

Documents torque specifications for critical fasteners to ensure proper oscillation integrity.

Parts List and Illustrations

Provides detailed illustrations and part numbers for easy identification and ordering.

Troubleshooting Guidance

Includes a troubleshooting chart to help diagnose and resolve common issues efficiently.

FAQ

Customer Reviews

Read what our customers say about this Stihl Brushcutter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)