1997 HP LaserJet 5000 / 5000 N / 5000 GN Service Manual (393 P.)

Service documentation for 1997-1998 LaserJet 5000 series with troubleshooting procedures, paper path diagnostics, fuser assembly removal, and DC controller specifications.

Manual Preview

Sample pages from the 1997 HP LaserJet 5000 / 5000 N / 5000 GN Service Manual (393 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

HP LaserJet 5000, 5000 N, 5000 GN (C4110-91033) — 1997–1998 Technical Service Sourcebook Specialized | LaserJet 5000 Series File.

- Nominal Print Quality: 1200 dpi is standardized to the maximum addressable resolution Requirements.

- Principal Securement Values: 100–127 VAC±10% at 50/60 Hz ±3Hz defines the electrical power input with 11 amps peak current Threshold.

- Rated Liquid Volume: Hydraulic fuser assembly achieves 392°F (200°C) nominal operating temperature for toner adhesion Mapping.

- Technical Power Rating: 100 MHz RISC microprocessor determines the formatter processing speed Configuration.

- Standard Working Temperature: Operating range sets 50–91°F (10–32°C) for optimal electrophotographic process Benchmarks.

- Defined Output Quality: 17 pages per minute (ppm) A4 or 16 ppm letter reaches the maximum print speed Range.

Professional Workshop Service Manual & Technical Specifications

Structured Installation Manual: HP LaserJet 5000/5000 N/5000 GN Service Manual-Nexus

Technical-Benchmarks: HP LaserJet 5000, 5000 N, 5000 GN (C4110-91033) // Calibration-Scope: Electrophotographic Printer / Engine Controller Logic // Maintenance-Category: 393-page technical reference documentation.

| Specification | Rating | Calibration-Standards |

|---|---|---|

| Print Resolution | 300-1200 dpi | Multiple resolution modes documented |

| Paper Capacity | 100-500 sheets | Tray-specific capacity specifications provided |

| Operating Temperature | 50-91°F (10-32°C) | Environmental tolerance parameters included |

| Power Requirements | 100-127 VAC / 220-240 VAC | Dual-voltage electrical specifications detailed |

| Memory Configuration | 4-12 MB standard | DIMM expansion procedures documented |

| Monthly Duty Cycle | 150,000 pages | Maintenance interval specifications referenced |

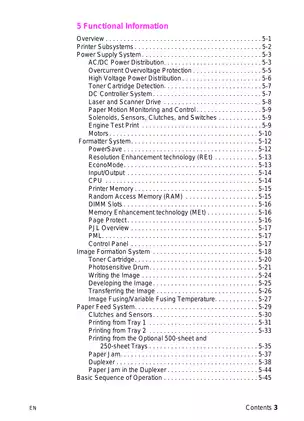

Technical units are distributed across Printer Operation, which details Functional Information, addressing Removing and Replacing Parts, presenting Troubleshooting procedures, and documenting Parts and Diagrams reference materials.

Systematically calling for comprehensive coverage, the manual documents the complete service architecture for HP's 17 ppm (A4) electrophotographic laser printer platform. The Printer Description chapter establishes foundational specifications including three model variants with progressive memory configurations, bidirectional IEEE 1284 parallel interface architecture, and dual-voltage power supply compatibility across 100-127 VAC and 220-240 VAC ranges. Documentation confirms operating temperature boundaries spanning 50–91°F with relative humidity tolerance between 20-80% non-condensing conditions.

The Service Approach section identifies field-replaceable unit methodology with emphasis on assembly-level component replacement. The manual references maintenance kit contents including fuser assembly, transfer roller, pickup mechanisms, and separation pad components calibrated for 150,000-page service intervals. Technical notes are provided for Support Materials Organization ordering procedures, with distinct part numbering systems for 110V and 220V regional variants and exchange program specifications for remanufactured assemblies.

Printer Operation documentation encompasses control panel menu structures across eight primary categories: Information, Paper Handling, Print Quality, Printing, Configuration, I/O, EIO networking, and Resets functions. The service mode procedures include page count verification, maintenance counter reset protocols, serial number configuration, and diagnostic activation sequences. Quality checks are addressed for Resolution Enhancement technology with four density settings, EconoMode toner conservation parameters, and variable fuser temperature modes spanning Normal, Low, High, and Vellum media specifications.

Functional Information systematically details six subsystem architectures. The Power Supply System section documents low-voltage DC generation at +3.4V, +5V, and +24V rails with overcurrent protection and thermal monitoring via thermistor TH1301 calibrated to 392°F fusing roller temperature. The DC Controller System manages laser diode modulation, paper motion coordination through photosensor PS401, PS301, PS402, PS403, and PS1307 flag detection, and main motor drive at 100 MHz RISC processor clock speeds. Image Formation documentation describes the six-stage electrophotographic process: cleaning via blade assembly, conditioning through primary charging roller with AC/DC bias superposition, laser writing at 1200x1200 dpi addressability, developing cylinder toner attraction, transfer roller positive charge application, and pressure fusing at controlled temperatures.

The Removing and Replacing Parts chapter provides exploded-view diagrams with numerical callouts for 47 major assemblies. Timing procedures are documented for DC Controller Board extraction requiring five rear-chassis screws and two internal long-screw fasteners, fuser removal via dual pressure-release handles with connector disconnect sequences, and formatter board withdrawal using captive thumbscrew mechanisms. The manual includes torque specifications for main gear assembly grounding screws, paper handling PCA mounting hardware, and laser scanner retention fasteners. Tool requirements specify Phillips #2 magnetized screwdriver with 6-inch shaft length and differentiation between self-tapping versus machine screw applications.

Troubleshooting methodology follows systematic fault isolation beginning with power-on verification through fan motor rotation observation, progressing to control panel display functionality, Event Log analysis of 30-entry error history, and paper path sensor validation. The document includes comprehensive defect identification matrices for image quality issues: repetitive defect ruler calibrated to photosensitive drum circumference of 94mm, fusing roller dimension of 86mm, and transfer roller spacing calculations. Engine test procedures bypass formatter circuitry to isolate print engine functionality through dedicated test button activation. Half self-test functional checks determine electrophotographic stage performance by interrupting paper motion mid-cycle for toner image inspection on drum surface.

The Parts and Diagrams section organizes components through three indexing methods: alphabetical nomenclature, numerical part number sequence, and exploded-view illustration cross-reference. Documentation specifies Support Materials Organization contact protocols, with North American ordering through 1-800-227-8164 and European SME coordination via +49-7031-142253. Exchange program availability covers DC Controller assembly C4110-69001, fuser units C4110-69002 (110V) and C4110-69003 (220V), laser scanner C4110-69008, and maintenance kit C4110-69006/69007 voltage-specific variants. The manual documents torque specifications for belt assembly through fastener identification tables listing M3x6, M4x10, and M4x16 screw classifications with corresponding part numbers and application-specific washer configurations.

FAQ

Customer Reviews

Read what our customers say about this Hewlett Packard Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)