2001 Canon iR1600/iR2000 Service Manual (496 P.)

Technical reference for iR1600 (16 cpm) and iR2000 (20 cpm) copiers with scanner diagnostics, image formation, and laser exposure procedures. Covers 496 pages of troubleshooting and adjustment data.

Manual Preview

Sample pages from the 2001 Canon iR1600/iR2000 Service Manual (496 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon iR1600/iR2000 (FY8-13HJ-000) — 2001 Specialized Detailed Original Collection | iR Series Section.

- Factory Assembly Gap: The copying speed is configured at 16 copies/min for iR1600 and 20 copies/min for iR2000 — representing standard output Requirements.

- Essential Load Capacity: Reading resolution produces 600 dpi × 600 dpi demonstrating the scanner system capture Threshold.

- Key Thermal Envelope: The fixing heater maintains 800 W power consumption for 120/230V supply establishing thermal energy Mapping.

- Primary Size Parameters: The photosensitive drum requires 30 mm (OPC) effective diameter for core imaging Configuration.

- General Fastening Values: Print resolution for copying is set to 1,200 (equivalent) × 600 dpi producing superior output Benchmarks.

- Integral Running Clearance: Operating temperature range reaches 15 to 30°C (59 to 86°F) maintaining environmental specifications Range.

Professional Workshop Service Manual & Technical Specifications

Verified Technical Manual: Canon iR1600/iR2000 Workshop Compendium

Assembly-Group: Canon iR1600/iR2000 (FY8-13HJ-000) 2001 // Technical-Scope: Copier / iR Series Container Logic // Assembly-Group: 600 dpi scanning resolution with 1,200 equivalent × 600 dpi output specifications.

| Documentation Coverage | Technical Systems | Reference Sections |

|---|---|---|

| Image Formation Processes | Laser exposure scanning mechanisms | Complete specifications provided |

| Electrical Circuit Architecture | DC controller and processor integration | Documented in Chapter 2 |

| Mechanical Drive Systems | Pickup, feeding, and registration assemblies | See Chapter 6 specifications |

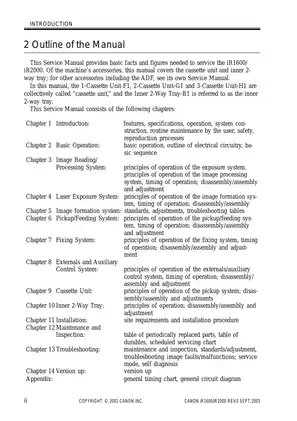

Factory procedures are documented for image reading and processing system operation, laser exposure control sequences, pickup and feeding mechanisms, image formation bias regulation, and fixing temperature management protocols across fourteen comprehensive chapters. The manual covers original detection sensor calibration including power supply circuit diagnostics, troubleshooting methodologies for operational faults, and maintenance counter reporting functions.

Electrical system documentation covers DC controller PCB architecture, high-voltage bias generation circuits for primary charging rollers, developing cylinder control mechanisms, and transfer charging applications. The resource includes connector wiring diagrams linking image processor boards to analog processing units, motor drive signal pathways, and sensor detection networks across cassette assemblies.

System operation descriptions cover indirect photoelectric reproduction processes utilizing OPC photosensitive drums with 30mm diameter specifications, roller charging methods generating AC constant current control at approximately 1110 µA, and semiconductor laser scanning synchronized through BD signal detection. Documentation sections include heat roller fixing systems rated at 800W power consumption, automatic background control for density correction, and registration clutch timing sequences coordinated with paper movement sensors.

Disassembly instructions are documented for copyboard glass removal procedures, contact sensor extraction requiring analog processor PCB disconnection, and fixing assembly separation involving thermistor inspection protocols. The manual provides detailed harness routing specifications, connector identification matrices across J-series terminals, and grounding wire continuity verification methods.

Wear limits are specified for fixing roller pressure measurements between 2.9 to 4.6mm at center positions, pickup roller surface condition evaluation criteria, and separation pad replacement intervals based on 50,000 sheet durability ratings. Service mode parameter adjustment ranges include CCD sensitivity calibration, main scanning direction positioning tolerances measured in 0.04mm increments, and leading edge margin correction values.

The documentation provides comprehensive wiring diagrams illustrating signal pathways between original detection boards and reader motor drive circuits, power supply PCB outputs distributed across full-time and remote ON/OFF systems, and cassette unit controller interfaces managing solenoid activation timing. Troubleshooting flowcharts address image density faults, feeding mechanism failures, and sensor detection anomalies with systematic diagnostic procedures.

Technical specifications detail copying speeds of 16 copies/minute for iR1600 and 20 copies/minute for iR2000 models, reading resolution capabilities at 600 × 600 dpi, and reproduction ratio adjustments spanning 50% to 200% in 1% increments. The manual documents torque specifications for mechanical assemblies to ensure proper thread engagement security during component installation procedures.

FAQ

Customer Reviews

Read what our customers say about this Canon Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)