1996 Yamaha TDM850 Service Manual (363 P.)

TDM850 technical guide detailing engine maintenance, fuel system, cooling components, transmission, electrical circuits, and suspension service procedures.

Manual Preview

Sample pages from the 1996 Yamaha TDM850 Service Manual (363 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha TDM850 (4TX1/4TX4) — 1996–1999 Analytical Analytical Primer | TDM850 Series Package.

- Engineered Net Mass: 229–232 kg (with oil and full fuel tank) represents the complete motorcycle weight Sequences.

- Defined Scan Resolution: For optimal performance, 849 cc displacement with 89.5 × 67.5 mm bore and stroke establishes the engine cylinder architecture Baseline.

- Rotational Force Data: 10.5:1 compression ratio — produces 1,200 kPa (12 kg/cm², 12 bar) compression pressure at 300 r/min Requirements.

- Principal Play Limits: Valve clearance is established at 0.15–0.20 mm (intake) and 0.25–0.30 mm (exhaust) cold Threshold.

- Advanced Temperature Range: Operating coolant capacity maintains 1.7 L (including all routes) with 0.3 L reservoir to upper level Mapping.

- Primary Enclosure Specs: Fuel tank requires 20 L total capacity with 3.1 L reserve amount for extended operation Configuration.

Professional Workshop Service Manual & Technical Specifications

Structured Technical Resource Manual: 1996–1999 Yamaha TDM850 Troubleshooting-Index

Series-Validation: TDM850 (1996-1999 model years) // Component-Focus: Engine Assembly, Transmission, and Electrical Subsystems Logic // Series-Validation: 370-page factory documentation with comprehensive specifications and repair procedures.

| Specification | Coverage Area | Documentation Status |

|---|---|---|

| Engine Systems | DOHC 5-valve, liquid-cooled 4-stroke parallel-twin, 849cc displacement | Complete specifications with clearance and torque reference data included |

| Transmission Assembly | 5-speed constant-mesh with shift cam and fork mechanisms | Comprehensive removal, inspection, and installation procedures documented |

| Electrical Architecture | T.C.I. ignition, A.C. magneto charging, electric starting system with safety interlocks | Circuit diagrams, troubleshooting logic, and component resistance specifications provided |

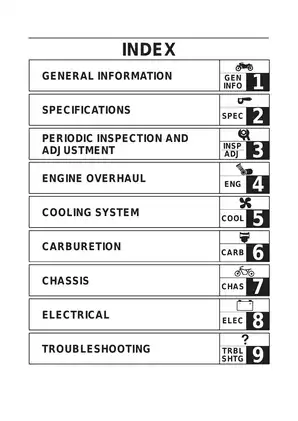

Systematizing the service groups into nine operational domains, the manual providing alignment specifications, engine operation data, complementary chassis system configurations, and electrical system diagnostics. The document consolidates general information protocols, references complete specifications spanning dimensions and performance parameters, incorporates periodic maintenance intervals with lubrication point mapping, examines engine overhaul procedures across camshaft and crankshaft assemblies, documents cooling system radiator and thermostatic valve architectures, addresses carburetor fuel delivery synchronization and adjustment procedures, covers steering components and suspension assembly protocols, presents electrical subsystem operation and troubleshooting methodology, and includes diagnostic decision trees for engine performance anomalies.

Hydraulic schematics are included for front and rear brake system architectures, detailing master cylinder configuration, caliper assembly sequences, and brake fluid specifications for DOT 4 compatibility. Steering component information is provided for headstock bearing installation, steering stem ring nut adjustment procedures, and handlebar alignment methodology. Inspection guidelines are provided for transmission gear engagement verification, shift fork wear analysis, and crankcase joint surface preparation protocols. Alignment specifications are included for camshaft timing mark positioning, rotor-to-crankcase reference points, and piston ring end-gap offset patterns. Reference data is included for oil clearance measurements on main journals and crank pins, along with bearing color-code selection charts that correlate crankcase and crankweb stamped values.

The manual documents torque specifications for the crankcase assembly to ensure proper structural integrity and gasket sealing function. Every major fastening point—from camshaft cap bolts through clutch spring installation and brake system unions—receives specified torque values in both SI and metric-kilogram units. Special tool requirements are identified throughout, including piston pin pullers, valve spring compressors, steering ring nut wrenches, and fork seal driver adapters.

Cable routing diagrams establish comprehensive harness pathways for ignition coils, brake hose positioning, throttle actuation systems, and sensor lead management across the frame structure. Lubrication point charts delineate bearing surfaces, oil seal application zones, and grease specification types—distinguishing between lithium soap base formulations for wheel bearings and molybdenum disulfide compounds for transmission and rear suspension pivots. The document provides component identification through motorcycle illustration symbols, enabling technicians to cross-reference exploded assembly diagrams with step-by-step removal and installation procedures.

Series-Validation: Multi-language support and periodic revision documentation for authorized dealer network distribution.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)